@sircaladin

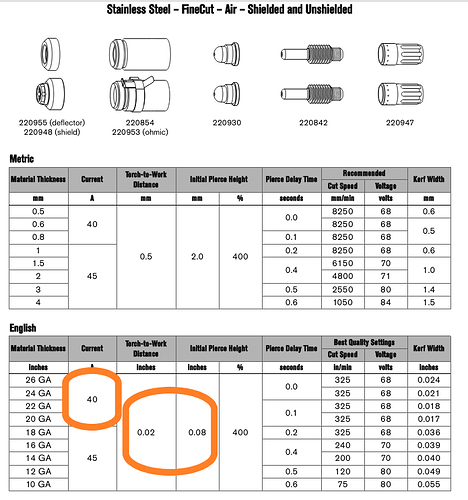

there’s a low cut height of .02 also very low pierce height of .08 and the slightly lower amperage of 40 amps.

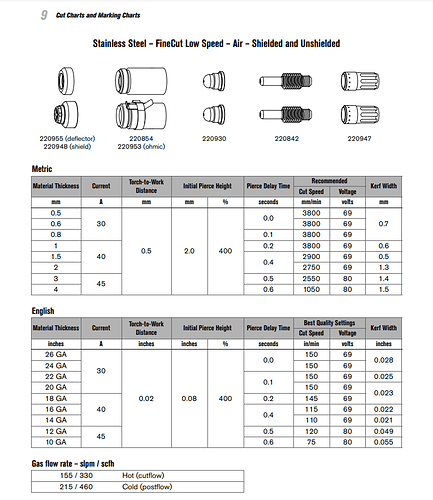

depending on how detailed project you’re cutting is or if you are cutting on a pro the can noty move faster then you also may want to look at the slow speed charts.

these slow speed charts also show a short cut height and pierce height as well as a 30 amp section for thinner materials

here is a link to some posts of stainless cut i ve done

@Langmuir-Johnny

Here are a few things I do when cutting stainless.

-Peel the plastic film from material.

-cut height .02" pierce height .08"

-short as possible pierce delay

-cut as fast as possible while maintaining geometry

(start with 35 amps at 200ipm,I have a powermax 85 so I am taking a guess here)

-Pour water on sheet during cut if geometry is complex and could build up heat.

-(with the Powermax I use Finecuts unshielded)

This is my rough approach when cutting stainless with my p…

2 Likes