During my spindle break in

run there was a terrible noise from the spindle. I believe it is the upper spindle bearing. Did any one else experience this? It really only happened at higher rpms, and it would come and go.

Sorry the audio didn’t come though. I think my spindle has a bad bearing. No load spindle sounds pretty good, under load it is horrific.

put an indicator on it for fun. I assume you will probably need a support ticket to have this addressed.

Runout is just fine. It almost sounds like one of the balls isn’t round. The sound comes and goes as it finds its place in the orbit.

If you can share a video with sound I’ll be able to let you know what I think the issue is. I’ll let you know the belt is sensitive to tension and too little or too much (usually too little) will cause a pretty terrible and cyclic sound to occur.

I started a ticket and Jake is helping me. He agreed that it was a spindle. Thank you though Daniel.

Hi- i listened to the video and responded to your ticket. To me it actually sounds like the belt could be cogging as a result of being far too loose. It’s possible that shipping vibrations/etc caused the motor to shift and thus lose tension. I explained the instructions needed to tighten the belt. If the noise persists then i would agree with your assessment that its a bad spindle bearing (we run all of these spindles through a condensed break in cycle all the way up to 8000 rpm which makes me skeptical of it being a bad bearing, but ill await your feedback).

Great, I will do that and send another video to you.

Adding tension to the belt seems to have fixed it.

Great to hear, thanks for the follow-up!

I havent opened up my spindle yet but is there an opportunity to swap pulleys to overdrive the spindle further? Or reduce to 1:1

I wouldn’t recommend overdriving further, but you can definitely underdrive it. We’ve made tons of pulleys right on the machine for dialing in the right ratio.

Is this due to bearings/ balance or reduced torque?

There’s not a lot of room to make the driving pulley larger- and making the driven pulley smaller has torque transmission issues.

Does anyone have instructions on changing tension on the belt ? I think I’m having the same issue (resonance at 7000-8000 rpm) and still waiting for response from customer support.

There are two upward facing allen bolts under the motor in slotted holes. loosen these and then pull snug, doesnt need to be super tight as its cogged.

I tried different belt tensions and it still didn’t fix the issue. I had a resonance setting the speed to around 6300RPM when everything is cold. I found pinching bottom part of the motor and the belt housing towards the front side of the machine eliminated it. I did some investigation and the plate between the motor and belt housing is only bolted on with two bolts, I think this allows it to rock back and forth (it’s not very flat) and resonate. I put some Kapton tape between the plate and belt housing and that helped, but now the spindle still resonates at 8000RPM, no matter what belt tension I use. Having just one bolt seems to help which I used to fine tune belt tension, but as soon as I tighten the other bolt it starts again.

I’m still waiting to hear from customer service, I’ll ping them again with the new info.

Did you make any progress with the vibration at higher rpms? I have the same issue.

I’m going to try honing the mating surfaces and see if that helps.

My issue was belt tension. Some fine tuning helped it quite a bit.

I don’t know if this could be contributing to the issue.

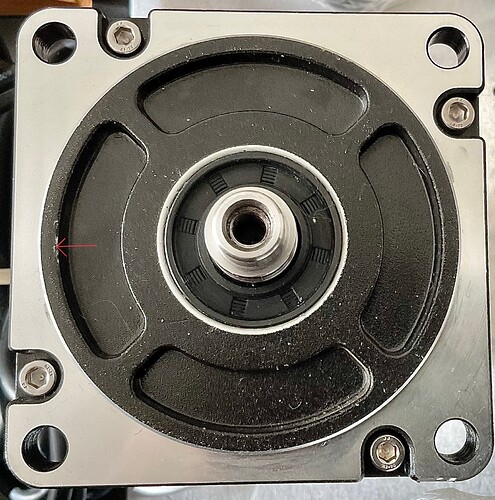

I see very little contact area between the cap screw and the adjustment plate. A washer placed underneath would help distribute the load better.

Problem is the cap screws provided are not sufficiently long enough. They are a little under 3/8” long and only 3-1/2 teeth are engaged.

So I tried a 5/8” long screw but it contacted the servo rib in this area.

The thickness of the plates together measure 0.440” so probably a 1/4-20 x 1/2” long cap screw plus washer would be ideal.