After getting off work this morning I went to my metal supplier and picked up 193 pounds of drops.

One man’s drops is another man’s treasure! At $1.05 a pound, I wasn’t complaining. I got seven sheets ranging from 16 gauge up to 1/8th inch. Most of it is 1/8th and that’s really thicker than I was shooting for. I’m still new to all of this and didn’t have my calipers with me. Still a decent haul. It won’t go to waste, I was just wanting more 16 and 14 gauge, live and learn.

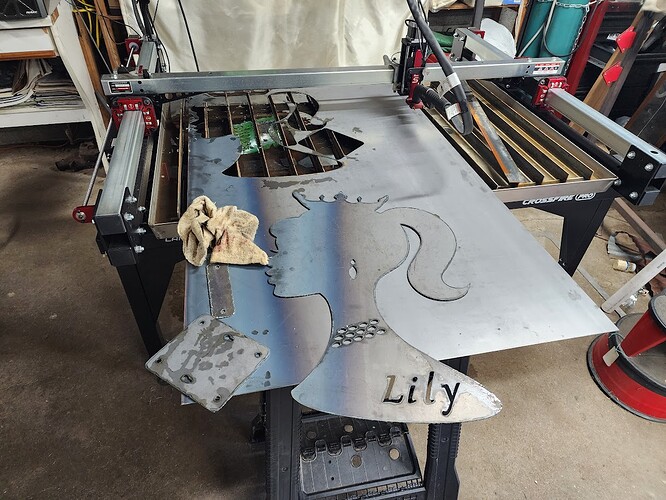

Then when I got home I got on the forum and caught up on what everyone else is doing and saw a post by @DonP on a piece he did and knew I had to do one for each of my granddaughters.

While it did cut just fine in 16 gauge (45ipm at 45 amps Titanium 45), the dross…oh the dross! I read where people have dross that basically falls off. That has not been my experience so far. That crap welds itself to the back of the piece, I’m going to be grinding for a while cleaning this up. Has anybody used anti-spatter spray on the back of the piece to try and eliminate some of that? Also I guess I need to pony up and waste some metal to do some cuts testing my ipm.