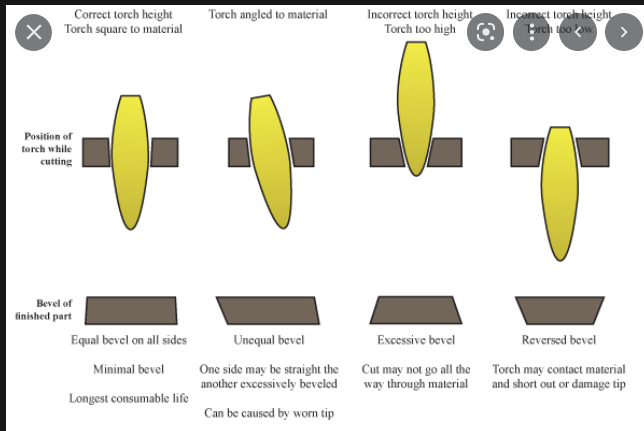

Thanks for the pics Phillip. So it looks like the angle is almost rectangular from the top to the sides. I will post some pics of my first test cuts, but I think the taper on my parts is way too big, what could be the reason of a too big cut height.

Also the edges on the lower side are very round, I tried the feed compensation, but THC fails stopped the trials.

I started the suggested 0.063inch from the LS vids. And used all settings from those instructions. When lowering to about 0.05inch at least the massive dross on the backside sometimes disappears on one side, which looks like the torch isnt really perpendicular to the workpiece/table. At least the slide of the z-axis is, but I guess I have to check if the Torch head really is.

Regarding my setup, I have the Crossfire Pro with the Razorcut 45 directly from LS. Just set up everything, completely new. Table and cutter didnt even run half an hour so far.

I really haven´t found some good settings, regarding amps and feeds. Excessive backside dross is the biggest issue, followed by tapers. It is cut through, but it all looks like it isnt cut well through.

The nozzle seems to be 0.9mm, as the bore gauge indicates. But it looks like the hole isnt centered in some way by eye. I think I will just change it, after I tested the angle of the torch towards the table.

At the moment, I really can´t test that much, because no matter how low I set the cut or piercing height, i get thc voltage losses randomly at piercing or mid cut. Workpieces are clean, clamp is right on an even grinded part of the workpiece.

So I hope its the moisture in the air, causing the arc to fail randomly. That wasnt mentioned in the troubleshooting guide as a possible reason for this, but I`ve read some posts here, mentioning some ppl had issues like that because of wet air. And my air is very moist, I can even see water in the stream of the air gun even when the tank has been drained jsut some hours ago.

So I`ll get me a refridgerated dryer.

Thanks for the responses so far.