All connections are correct,ive been thru diagnostics that the factory sent me,waiting for a response back from them on the next steps.

That doesn’t seem right. If the torch fires when you short the end of the cable that’s plugged into the cutter then THAT port is the torch on/off.

@MikesFabrication the torch on/off port on the control box has spade connectors on the inside. check to make sure those are fully seated. It could also be the port itself that’s bad. I’ve seen a few posts about that.

One of the tests they had me do was checking the Torch port,and its wiring,visually and with ohm-meter.

You’re right. I was confusing that with the people that plug the torch firing wire into the VIM.

I played with the connections on the Cutter and the VIM box,and got it to fire and cut. Now,we pulled a couple ready-cut files off of the forum,and they partially cut,and I get a Low Voltage detected message(100-200v shown). Fires at 300v,drops to 95-126 while cutting,spikes to 300 when it stops suddenly. And a Misfire-detected I really dont like the way the cables plug into the VIM box,they feel loose. All cables are tied up on the table and the machine,so nothing is loosely flopping around,VIM is velcro to cutter.

Is your air flow from the compressor keeping up with the demand?

Yes,I have 120psi currently,its a commercial compressor,makes 150psi,18cfm. Another thought,I put a regulator on the inlet to cutter,maybe run it direct?

Is the plunger stuck in the torch head? Should be able to push it up with your finger. It should pop right back.

it will cut a good chunk of the part before it stops, but i will check the torch

Probably not the problem but last week my Fusion 360 post 1.6 download to Fusion had a problem. It would fire and start to cut and the torch would raise up and shutdown. Reloaded new Fusion 360 post 1.6 download in fusion and now works perfectly.

I have not used fusion personally, i have been getting cut ready files from fireshare to test the table.

Dumb question on but have to you tried a different fire share download?

Your Manual will have a stated inlet pressure it should be regulated going into your machine.

I was thinking maybe you had some sort of restriction that may cause a pressure to drop during operation after a little bit of time.

we uploaded the LS Keychain,a simple test-piece.It fires and will cut,until it needs to change position for next cut-line,then it throws the fault,you can restart from that point,cut next step. So it cut the “L” and stopped,moves to start “S” Fires,and stops,Restart,Cut out the perimeter. I removed the regulator I installed on the inlet,so its not an air-issue,Compressor isnt kicking on during cut,so not a shop voltage-drop issue. I checked the tip,nozzle components,all as they should be. We have tried 4 different files,all with same issue.

It sounds almost like a pierce delay issue.

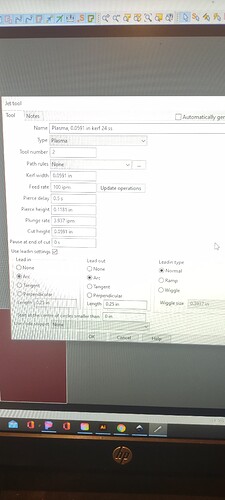

Its not mentioning the delay in the fault,its set at .5 cutting 24ga Stainless

Try .7 or more maybe even .9 see what happens.

Your lead in and out are set to 1/4" should be like

.09 not .250 . I don’t use Sheetcam but it looks way to long.

Ok,Thanks we will try that next.