Hey all

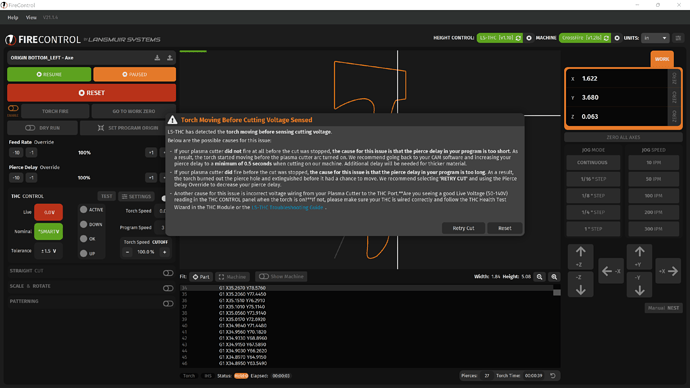

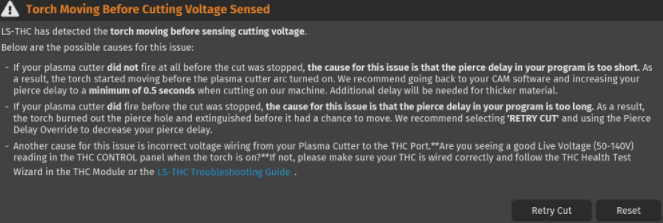

I am having trouble with cutting my Fusion 360 design. The torch fires for a second or 2 then stops flashing the error. Pierce delay is too long.

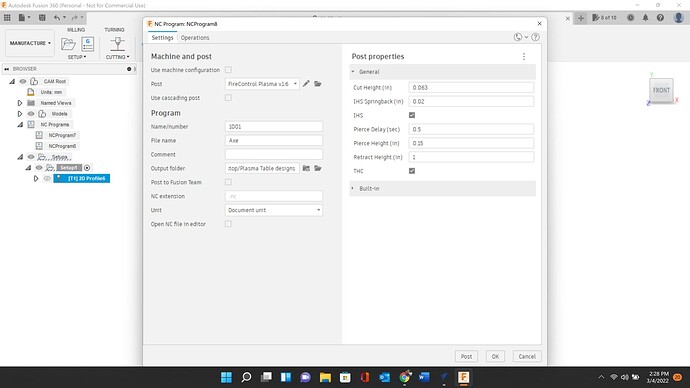

I have tried adjusting the pierce delay in the post-process window.

Any help would be great.

Matt

.5sec looks good in fusion 360. under .5sec will be too short for the Langmuir

Flashing the error code from where?

does the torch manually fire properly?

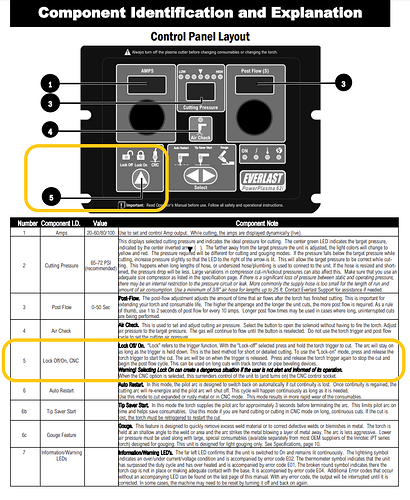

What cutting mode is your Everlast set to?

https://www.everlastgenerators.com/sites/everlastgenerators/files/downloads/467c5d5d3d45cd73503e4f44901e71c7.pdf

1 Like

dang you Manual-Man…thwarted again by you and your devious ways…

I was gonna do that…but Nooooo…you jumped in faster than a fart spreading in a room…

the other thing to consider…possible issues with div/raw voltage from the CNC port…

1 Like

working at the computer this afternoon and I have 4 monitors going, easy to see what’s happening.

A screen for everything.

We should get a answer bot for this forum and we modify its cues and responses .

Hmmm… Toolbot may be a good name.

1 Like

The Everlast is set to CNC and I have the machine torch.

The torch fires then stops. Then the message pops up. and there is a little hole in the metal.

Also the consumables are brand new.

you can increase the pierce delay in Firecontrol at " Pierce Delay Overide" but make sure the file you post from fusion 360 in at .5sec minimum.

Work clamp directly on the material being cut?

Passed your THC tests?

yes, past the THC tests.

Should I be increasing the delay?

I have the torch set to 20amps and 65psi. Not sure if that matters.

Thank you so much for being fast on the response.

nicaDd

March 4, 2022, 9:30pm

10

yes increase your delay to about .8. Some cutters require a longer delay that what specs tell you.

.8 seems to be a good starting point and you can decrease/increase from there.

1 Like

Yes , Yes.

What he said.

Coppersmithcustoms:

20amps

pretty low but maybe an Everlast user can post some 20 ga mild steel settings.

Your making a hatchet out of 20 ga ?

Lol. I am on an axe-throwing league. It was a nice shape to test. Figured I could do something with some small hatchets.

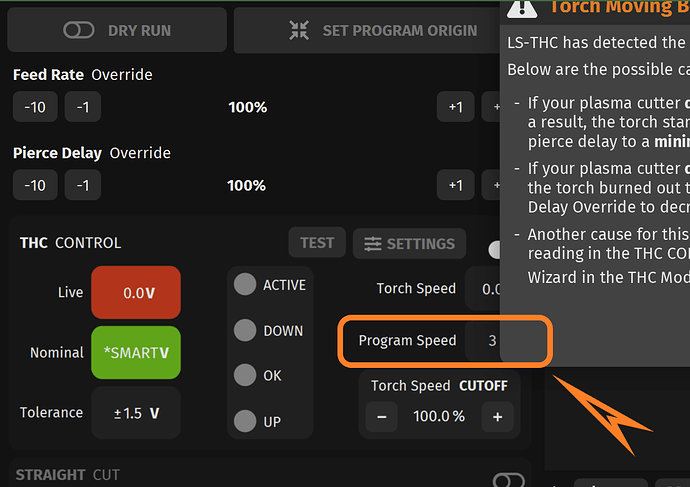

I increased my delay time and it seemed to run longer. It basically ran until it cut through the metal. Then stopped. Am I missing something in the feed rate?

Lets work down the list.

Can you post your nc file?

How is your THC getting its voltage measurement?

CNC port RAW, CNC port divided or RAW from inside the case

what speed is this?

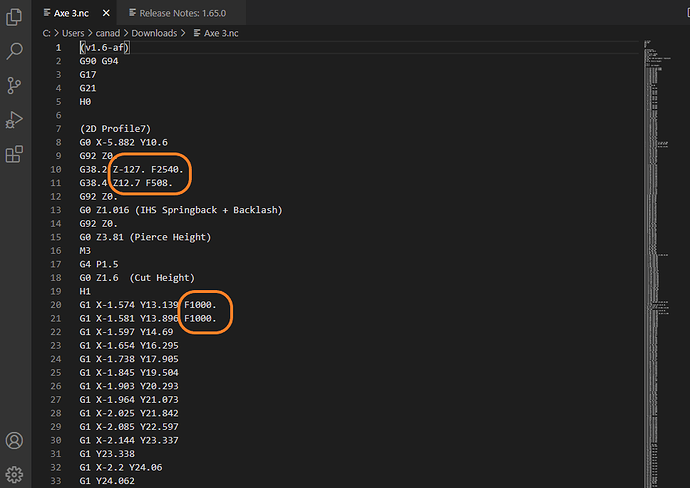

I utilized the setup @toolboy shared. CNC port for on off and raw from inside case.Axe 3.nc (8.8 KB)

The NC file i sent has that # at 990

I thought it might be too slow so I increased the speed.

I don’t know.