Thank you very much!

Okay I have found a couple old post where you talk about replacing these parts. Im out running around looking.

What is the plastic tee?

I should have taken my machine apart before I left buy did not. Home is 30 minutes away.

Also do you recommend 1/4" or 3/8" regulator?

All my other components are 3/8"

Thanks

T is 5/16"/8mm

What ever size regulator you want to use

Thanks appreciate the quick reply

On the front of you Razorweld there is an air switch that will help Replicate when the torch is cutting. Most likely you will have to Open the Case, 10 screws- 6 side, 4 top and end of handle, and set your Regulator to 85 -90 psi.

At that point the air switch comes in handy.

Hope this helps - Jim

I did start there really need to get these cuts done.

But I also ordered the 5/16" pneumatic Tee and a 1/4" ARO Ingersoll Rand regulator. After George’s post I did some more search through the forums and this definitely seems to be a reoccurring problem. Most of then have George repeating himself over and over. Thanks George for your patience with those of us slow learners.

You need to work on getting clean/ dry air as well. In pics can see a lot of moisture signs on consumables. Your consumables will last longer the cleaner/dry air supply to plasma torch is.

People also don’t appreciate that this isn’t just a regulator.

It’s a regulator and filter.

I wonder how many people ever change or clean the filter?

What do you mean by “generator” for your air? Is that another term for compressor? Which specific compressor are you running? What is your filtration/drying setup, specifically (the logic path from compressor to your plasma)?

You mention your air is “dry” but I didn’t see you mention any drying components (desiccant, refrig air dryer, etc) between the “generator” and the plasma.

I would HIGHLY recommend having a big desiccant volume and then a motor guard (M-60) immediately following, right before your plasma.

Every time I think I have this thing whooped/figured out its something new. Spent many hours today reading every air supply and dross thread I had time for.

After addressing the 15psi drop in the air supply and adjusting the cut high with a feeler gauge I was having good top cut and horrible bottom dross. Worst ever…

At some point I turned up the amperage to 45amps. I had been cutting at 40amps. As I turned the amps down the cuts got better. I stopped at 35amps and 120ipm on 14ga. 95% of what I have cut has been 14ga. I like the weight of the pieces and stiffness and the cost is an extra $10-15 per 48x96 sheet versus 16ga.

However I still had some dross and a beveled cut. I need to check my program settings and do a few additional cuts as well as get the air regulator completely sorted out. Its currently running at 80-85psi when cutting. I pushed the air button as suggested to set the pressure with the cover off but for whatever reason it’s 10psi high when I put the cover back on and in operations. I thought about running the cutter with the cover off so I could adjust the pressure but that was to sketch for me and running out of time today.

Also going to have to play around with the cut height a bit. I’m kinda at a stop right now because the cut quality has become undesirable. So I’m going to take this time to do some extra cleaning on all my gantry rails, check my bearings and lead screws just to put this machine back in top shape.

On that note before I do all the cleaning I’m going to get the regulator and cut height tuned it. I think I had some compounding issues and started chasing the tail of the dragon…

So far 1) Amps were to high 2) cut height was off but I over compensated initially 3)Consumables had signs of wet air 4)my air line between the tank and the water separator had water in it (I put and open coupler on it and ran the compressor for about 15 minutes to dry that out with the tank valve open slightly also. 5) Chasing to many tails.

As I read many many times today… It all works until it does not. I need to upgrade my air drying system. I want a passive system. My separator has been working fine for the last 2 years. Now it’s not so time to upgrade. There is so much information on these forums.

If I read a little faster life would be easier. I will have sometime Thursday to post some cut and finish my fine tuning. Thanks for every ones help so far!

Ordered a Motorguard 30. It will be here tomorrow

When moisture is involved, you can throw much of everything else out the window because it will lead to inconsistent cut quality.

Once you get the moisture issue taken care of, you’ll see consistent results (and actual differences) when you change one factor in your test cuts.

As for the “amps too high”…you’ll find many people run everything at the full 45 amps on their Razorweld.

Just run it at a faster feedrate. Bottom dross normally means too slow of a feedrate.

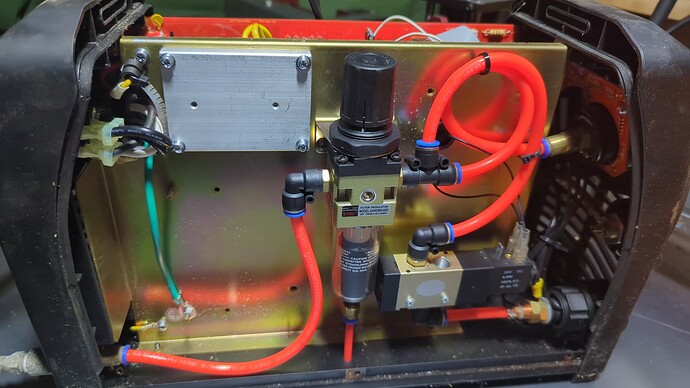

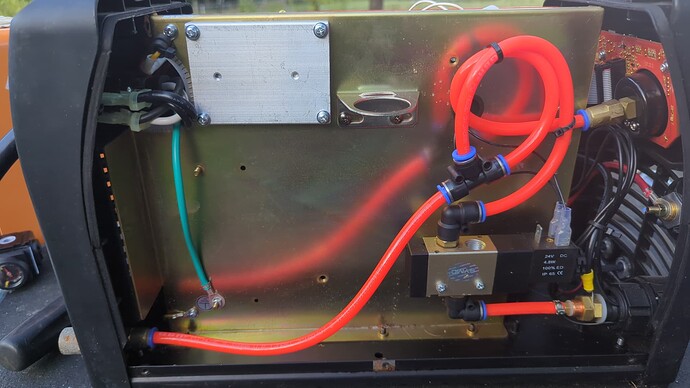

After many hours investigation I think I have 2 problems, bad regulator and water issue.

Bought a new regulator and mounted it to the outside as recommended so now I can adjust on the fly.

I have picked up a motorguard filter kit and derale 15300 aftercooler. Pretty sure I’m going to run the after cooler after the tank. Air compressors have been made with bottom drains forever. I’m not concerned with draining the tank. I empty my tank after every use. I still need a couple fittings to get the motorguard and after cooler installed.

Just needed a

5/16 Pneumatic Tee (40 piece kit ($18)

1/4 double male nipple ($3)

New regulator (ARO 1/4NPT ($45).

Yep, you could have picked up my kit a little cheaper.

Damn it. Sorry George I thought you had closed up your shop.

Shop yes, store no.

Well Sorry about that… I would like to order 10 Nozzles and Electrodes for the Rzr45. Online only shows you have 5 electrodes left. When do you think you will have more? Thanks

Glad to brought that to my attention. Check this out now.

Or you can save a few bucks and send me a email.

Email sent

Thanks

EDIT:

Sent the email the link listed on your website and it got rejected

Sorry, no email so I don’t know were you sent it.