Since my 2x4 expansion I’ve had a little whip over 200 ipm. Tried tensioning the screw with decent success but too much tension would stop the y motor. So, I went ahead and designed and built a rotary nut system similar to the XR. Everything went together smoothly. It jogs great, but it stalls the motor out above 100 ipm. I’m aware that the 425 oz nema 23 on the y axis is the biggest nema 23(as far as I know). A nema 34 would work but I’m not sure about making it play with fire control. I know there are a lot of setting on grbl you can change as far as travel distance etc, but I’m not sure about wiring in a nema 34. Anyone have any input or ideas to increase the power?

Hopefully you figure it out!

I see a thick belt and I’m thinking just like a roots type blower, you’re going to suffer some loss of power driving that thing

Any way you can just cut some more, set aside profits, and just buy a larger table? It’s how I went from a Crossfire with XL to a Pro in less than a year and I only do this as a hobbyist

It’s not really a money thing, mostly a size thing. Shop is 60x60 and I need room to pull equipment in, so plasma table has to stay small. 2x4 seems like a good size so far.

I also like to tinker with stuff ![]()

I suppose I could try a bigger pulley on the motor and see if that gets me a little more torque. Would have to adjust some speed settings

Well I’ll be watching with great interest!

I too considered moving to a ballscrew style movement on my Pro, mainly to make my table a 4’ x 4’ vs the odd 4’ x 33"

Did you incorporate some sort of gear reduction or something? Guess it helps to ask if you’re running an old Mach 3 table or Firecontrol because you can’t adjust for a difference in stepper resolution/turns per inch with Firecontrol but you can in Mach 3.

I have a newer machine with fire control. Although I still have the old mach3 control box sitting in the closet. That’ll be my tube notcher someday, but shhh…

You can change the turns per inch with a fire control machine. I didn’t know that until I was doing some digging on here about a rotary axis. I’ll link the post if I can find it easy. Fire control is basically a grbl controller, so you are able to change settings with another program and the settings will stick in firecontrol.

I ordered a thinner belt and some different springs to try. My current spring washer that pushes on the bearing is rated for 60lbs force but I don’t have it compressed 100%, maybe that’s too much. It turns fairly easy by hand, but I forget how weak a nema 23 actually is.

Especially a stepper motor driving a high inertia load. You could play with your acceleration parameters to get around some of that.

OTOH, a Plasma cutter is a fairly light load for a CNC system with the only real load being the drag of the Plasma Cable. Perhaps you’ve gone too far making it ‘robust’…

I wish I could eliminate the spring washer completely. But the bearing has about 6 thou of play. I could have done opposing tapered bearings to eliminate play but then you run into housing issues. The pillow block was a perfect fit for this application.

I’ve only got 200-300ish wrapped up in this experiment so I’m not out a whole lot if it doesn’t work. I just am not happy with the cut quality at 250ipm on the ends of the table. Under 150 or so cuts perfectly. But I’m a firm believer of run the cutter at full tilt and let it eat.

I’ve pretty much got the whole table modeled in cad at this point ![]()

Gosh! I would have though that you’d start with that before even buying parts! Model the whole thing including animation! ![]()

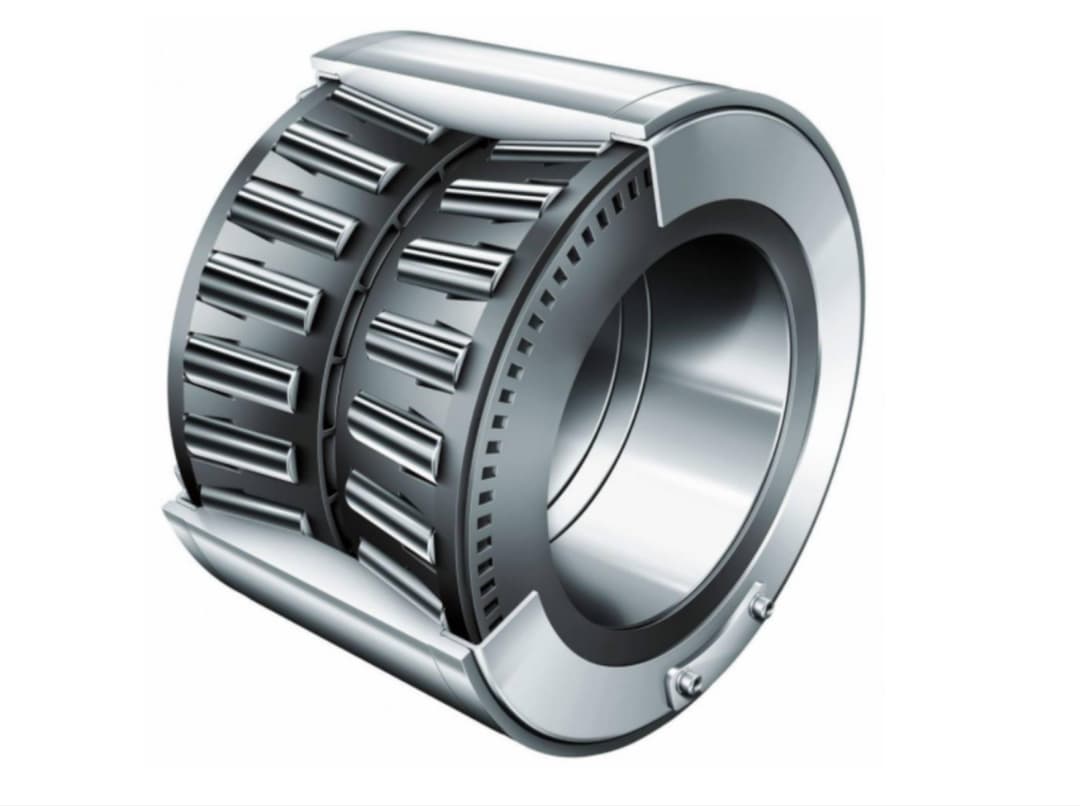

I got the machine turning at 200ipm with a 1/2 belt and a 20lb spring. Still not too happy with it. I think I’m going to need to switch to a dual taper bearing like this to eliminate the need for the spring pressure preload.

Switch to Clearpath motors, I also used JMC stepper servo motors.

https://www.jmc-motor.com/product/list/24.html

Another option is change the stepper motor drive current setting. You could also change the 36V to 48V power supply (bigger motors can handle more current). LS runs their motor current fairly low because their idled motors aren’t very hot.

Actually, the REAL benefit of the higher voltage is faster rise time on the current. This allows faster stepping for the same current value.

GRBL doesn’t care about motor power. It’s only interested in the steps per unit distance, acceleration parameters, and max speed. The NEMA34 motor would have the same steps per rev so that wouldn’t change. A larger motor would handle more current, but at a cost of higher inductance (which lowers current rise time). As pointed out earlier, going to higher voltage would help in this respect.

I’m not familiar with the motors that @holla2040 mentioned and maybe that’s the answer as long as you want this hefty drive system.

So if I’m thinking this through right, a nema 34 and a driver that pull off their own power supply by still are run by the LS board might give me the solution I’m looking for. I really think this is worth pursuing to eliminate whip. When it was running at 200 ipm it was smooth as butter. I really don’t want to go back to the way it was before and just limit my feedrate.

This drive really isn’t very “heavy.” Just a small piece of plate and a bearing that take up the most weight. I think the issue is the rotational mass of the pulleys.

I wasn’t going to go into this detail but agree ![]() .

.

Yeah, that’s called ‘Inertia’ and Stepper motors don’t deal well with high inertial loads. The way to address this is to tune the acceleration parameters and have the response time (AKA high enough current rise time to meet the needs) properly set.

I must be missing something. Why would you do this? Besides faster, what is the benefit? How fast do you want to go? I have to say the design on Fusion is very impressive.

He feels the need for speed.

Because I lengthened my table to 4’x2’. ~6’ long 1/2 lead screw whips over 200ipm and sacrifices cut quality. I’m not looking to go any faster than 300ipm

Yea but these table already accelerate like poo. Not saying I won’t have to adjust it a bit, but I really don’t want to do that until I have to.