These values will work pretty much for any torch you are running at 45 amps.

That is 0.1mm/.040" not 1"

i dont understand how that can be if there are different sized consumables etc. just trying to make sense of this

im sorry i dont understand, what is not 1 inch

The cutting tip size, I think you called it a nozzle.

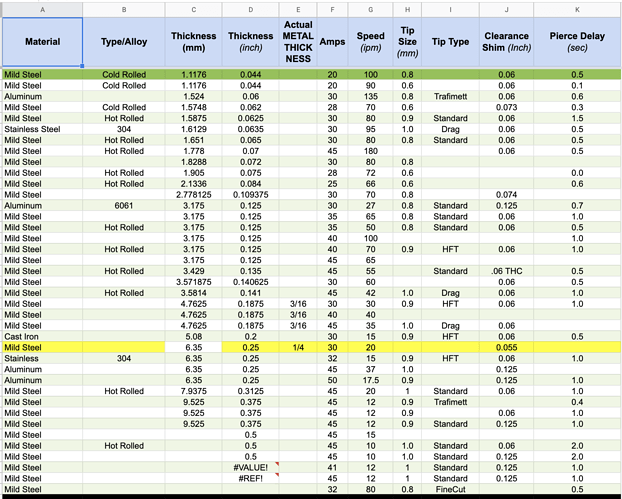

no, on langmuirs video, he says if youre using a crossfire or crossfire pro to set the value of the nozzle clearance diameter to 1 inch, and the clearance height to .4 its under the creating a plasma cutting tool portion of the cam tutorial. in the settings of this cut chart from fireshare is what im referring to btw. the nozzle diameter and kerf widths are changed through the materials/thicknesses. im asking if that indicates different sized consumable tips and or torches. or is there something about different kerf widths/materials/thicknesses im not understanding? wouldnt the same tip burn the same amount of material (kerf) no matter the thickness? using thc btw not sure if its relevant

Your post stated (settings were 1" nozzle diameter) there is no 1" nozzle. And no there is no different size cutting tips that Langmuir or I sell. There are some Chinese sellers that say they have different sizes. The kerf will get larger on thicker metal because your cutting slower.

im referring to the nozzle clearance diameter. in the video, they tell you to set the value to 1". i appreciate your input also. is there somewhere i could learn more about kerf width discrepancies through different thicknesses?

The nozzle clearance is to my understand is so the software knows how wide to torch head is for clearance . It would be approximately the diameter of the torch. 1 inch is used as a standard on that for some reason.

What happened to the Google sheet Cut Chart? The most helpful sheet is gone…

Yes, I can’t find it. Thank you.

i just want to add that i have been trying to eliminate a huge dross issue with 3/16 cuts. and the settings on this chart for 3/16 are ok but very very messy.

Turn your amps up and speed up in 5 ipm increments until you are satisfied.

That’s what you get with a crowd sourced settings chart. Most of the crowd doesn’t know what they’re doing, but that doesn’t keep them from posting their awful settings in the chart.

You’re better off guessing, based on your experience with other thickness, and doing test cuts to adjust.

I have a RW 45, I cut 3/16" at 55-58 IPM, 45 Amps 70PSI and I get what I consider dross free cuts

45 amps 60 ipm 75psi seems to be the money spot on my rw 45. i will post pictures of the cuts when i am finished cutting. as for holes, i slow it down to about half that speed and have my lead ins start near the middle of the hole.

Cod Beans, delicious. ![]()

In the current cut chart at Plasma table Cut Chart - Google Sheets, column K is “Tip Number”. To what does that refer? Looking at the “Torch Diagram” tab of the spreadsheet, I don’t see anything that indicates what a tip number is.

Also, what tip actually comes with the Razorweld 45 machine torch head? I couldn’t find anything on the Razorweld site or any of the documentation that I have that indicates this.

They are 45/50 amp tips.