So new to the cnc plasma table world, i have a razorweld 45 with a crossfire pro. Brand new setup, made probably 3 or 4 perfect cuts, then the torch started turning on and off multiple times during the part. Doesnt throw any errors and the table finishes the run, just the torch turns on and off multiple times during the run. Heres what I’ve tried:

THC on and off

As dry of air as i can do at the moment(moisture trap/filter, then desiccant dryer, then regulator/filter/moisture trap)

Different cut speeds/pierce delays/amps

Grounded directly to work

New consumables

Ample air pressure, have adjusted the regulator in the machine from 60-85 psi, regulator on shop air is set at 110

Cutting in 2T

Outlet is wired for 60amp with 6awg wire

Tried the “straight cut” program in firecontrol thinking it was an issue with my programs from fusion, still did it

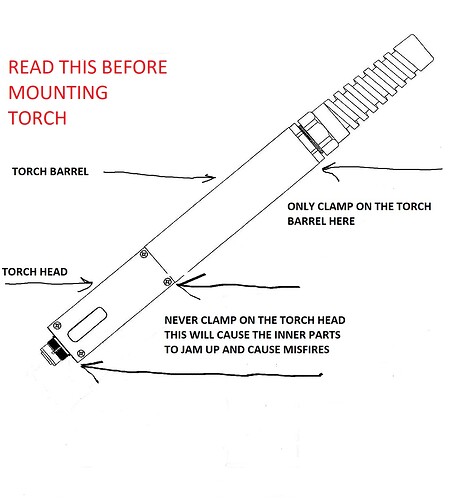

Machine torch is clamped correctly on the “barrel” above the plastic

I will say I accidentally left it on 4T for my first several cuts(noob me didnt read the manual first), and it actually was some of my better cuts so far, but switched to 2T when it started having this issue and it actually does it far worse on 2T(hopefully i didnt mess something up cutting in 4T?)

I did notice at one point the torch quit firing when the machine was being told to, did a thc test and it wouldnt fire, wiggled the connector on the front for torch fire and it started working again, took the torch fire cable that comes with the kit with the scotch locks and bypassed the connector with that cable, torch is firing but still doing the same thing with cutting on and off

Idk im at a loss, if anyone can help thatd be great