Playing with this today, 15 gallon drum. Looks like it will work.It probably had less than a gallon left in it while laying on its side. Waiting for batch 2

Seen this after looking for water additives. The part in parentheses is what I’m concerned about.

Plasma Quench Home Brew - This is very similar to Plasma Quench but you purchase and mix a few chemicals. If your really interested you can look up various recipes but the chemicals involved are; Sodium Nitrite, Physan 20 and sometimes a color dye. The experience with the home brew was about the same as with the commercial brand and (after research the use of Sodium Nitrite and Physan 20 after high heat and uv exposure with atomization is not good for humans.)

i just ordered the same 13 gallon tank, and the van stone flanges, so a little bit of a hybrid between two systems here.

Checkout Zoro online Cross reference all the fittings , Great Price $5.00 Shipping

that’s what I’m doing using parts from each, also I’m trying to figure out how I can just hook my air compressor up to the tank and fill up instead of buying a tank with motor.

Not completely done fitting everything up but I’m getting closer. Once the plumbing is done I just need to figure where I want to mount where the air hook up will be. I’m hoping to T off one line coming in. Coming in it will go Air regulator-----Air Dryer then T---- One line will go to the plasma and through the everlast dryer---- The second line will go to another regulator that will bring the PSI down to 1psi ish for the reservoir.

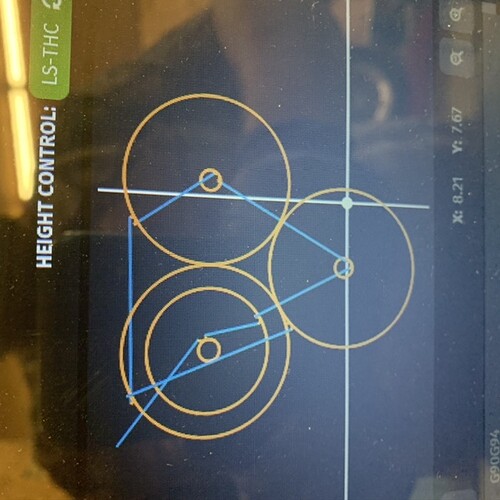

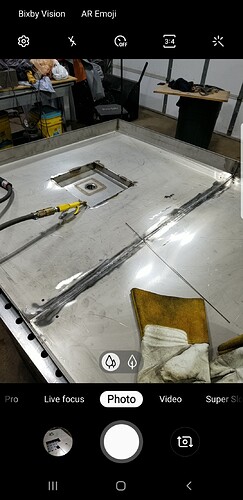

My harbor freight knock out kit wouldn’t make a big enough hole for my new drains so I used the plasma to cut it. Made a 2” hole program, lined torch up inside bore, used 1” incremental movement in fire control to move to where X&Y zero should be then let it rip. Holes came out good, will finish plumbing tomorrow. Drains are “bar sink” drains with stoppers. I’m hoping the stoppers will help catch debris before getting into the pipes.

Also tried to make a dimple die but I think the OD and ID were too close together. Didn’t move the metal much. 1/2” bolt through the middle

I was going to do the sink strainer idea for a drain also…once I get my table…as for straining out the smaller particles I am throwing in a 1/2" irrigation strainer with a clear plastic mesh screen. that way I increase the longevity of my cutting fluid.

I have the same ideal but I’m going to use 2 of them. I’ll have the 1st filter between the water table and the tank filtering water before entering the tank. I’ll have the 2nd filter before the pump filtering the water coming back out of the tank. I’m going to also put a piece of 3M pad over the drain holes and surround that with magnetics to catch more debris.  Doing all of this may be an over kill but I want to try and keep my water as clean as possible.

Doing all of this may be an over kill but I want to try and keep my water as clean as possible.

1.5” drain drains the table a heck of a lot quicker. I put a ball valve on the end of the table to allow drawing the table it’s it’s real nasty and I don’t want it back into the tank. 16 gallon storage tank should be here today.

How thick is the pan? How did it weld? Looks like it stayed pretty flat .

Looks great! Can you come weld my leaky pan?

It’s only 20 GA. It wasn’t bad. I backed it up with aluminum and cooled every 3 inches.

If I have air fare and lodging. Lol

that is a great idea for the pan…might do that myself…ahahahaha…in my dreams

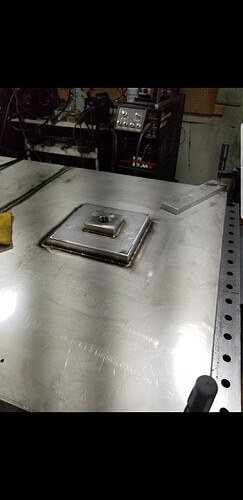

Thanks, right before the Pro came out I was looking into building my own table. But since it was such a good deal I couldn’t pass it up. The sump idea came from my initial plan for my table build. Next weekend I’m going to work on the filter system that fits into the sump area.