25’ PTM60 machine torch

I am using the supplied IPT 60 torch and cable.

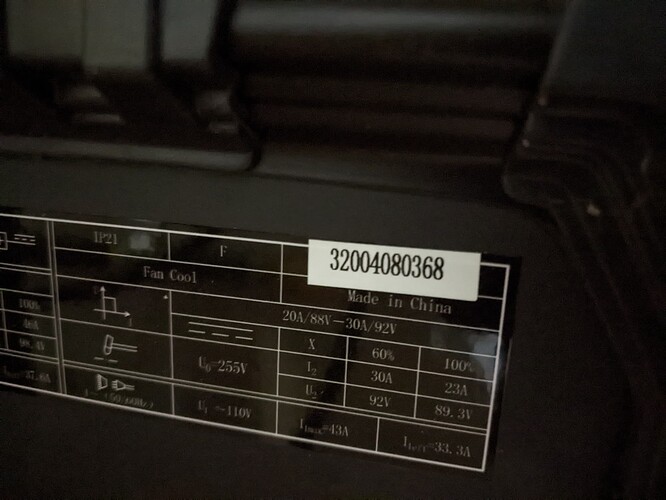

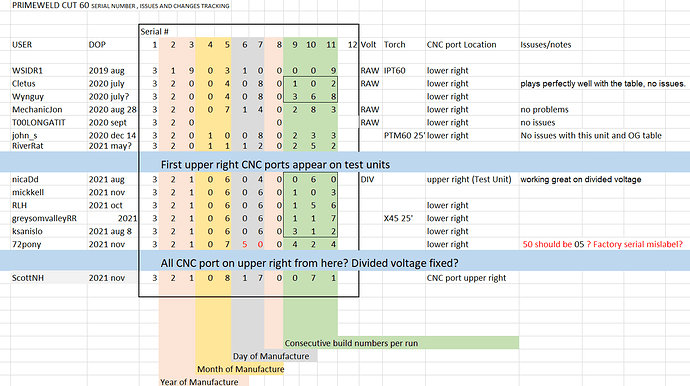

This thread is pretty interesting to me. I have a Cut 60 that will be paired with my incoming cf Pro and have been watching this information like a hawk so that I take the most reliable path possible. Heres my cutter for the chart. It’s neat to see the evolution of design.

Thank you for the information

RAW voltage is the path for your machine ![]()

also looks like your machine was produced on the same run as @Cletus

I am going to label that in red. It has to be a mistake at the factory. I am sure its July 5… Hopefully we get some more serial numbers near your sto help solve this puzzle.

I’m running the PTM60 torch also.

My serial number is: 32007140138. Purchased, 9-5-2020.

My CNC port is on lower right, looking at the back.

PTM60 Torch also.

Thanks,

Chris

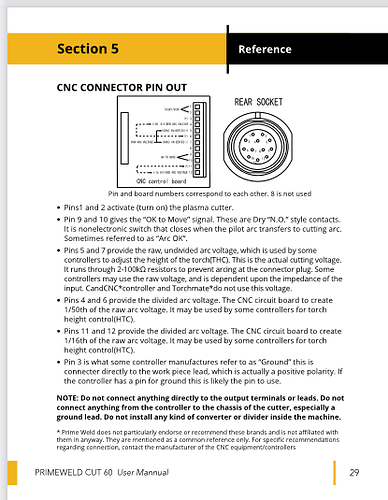

Can I pick up the Raw voltage from the CNC pin-outs or do I gotta pop open the machine and pick it up from there?

Use the cnc port for the trigger. But I would pickup the raw voltage from inside the plasma cutter for best results.

i would agree with @mechanic416. Dustin from primeweld had asked me to create a step by step instruction sheet for him in case anyone was going that route. see below.

raw voltage hook up…seems no rhyme or reason concerning location

I pulled it from the plug and it seems to work with out issue. The protection resisters lower the voltage but the THC does not seem to care. I run the trigger and raw voltage through a 4 wire 25 foot lead and there are no issues to report.

purchased my cut60 on 8/28/2020 serial # 32007140105 I use the Div the only issue I have had when I first got my table using the hand torch I would get an error but it was the THC giving the error and to fix it I would jog the z axis up and down a couple times before cutting but since I have gotten the ptm60 machine torch I have had no problems with the cutter and the table. But Fusion 360 freezes on me all the time when sketching.

Only recently received my Crossfire table and got it up and running. I already had a Primeweld CUT60 (purchased Nov. 2020), but also ended up ordering a Razorweld Razorcut 45 with my table since I was concerned about the compatibility issues. However, I have not had any issues so far with my CUT60 (only done a few cuts with it hooked up to the Crossfire, but hoping to get a bunch more time in over the next two weekends). The serial number on my machine is 32009420353. I’m posting this as I had read through the thread and @72Pony had a serial number with 50 where the day is expected and mine has a 42 there so maybe not an anomaly since our machines are from different years. My CUT60 has the CNC port on the lower right when looking at it from the back and I just use that for torch firing. Wired up to raw voltage for the THC. Now I have the Razorcut 45 as a spare (not a bad thing though).

Tin,

I can report (it’s early yet) no problems really yet. Divided voltage on CNC port.

I bought my cut60 summer of 2021 the cnc port is at the bottom right my question is has anyone tried it with the XR yet? Cause i just got my XR up and running all thats left is hooking up the cut60

What is my best rout raw voltage thru the port or in the machine or will divided voltage port work on XR

If anyone has used the cut60 with the XR or has any good info please share with me.

Thank you

It really don’t matter what table you have. I would go with raw right from the plasma cutter, not the cnc port.

as mechanic mentioned, RAW from inside the cutter. i have step by step instructions with pics if ya need it.

Here is the most recent directive from Langmuir regarding the Primeweld Cut 60.

I had mine wired through the CNC port and hadn’t had any issues but you will note that they indicate the multiple users had gone from experiencing no issues for months to experiencing spikes in voltage. After reading this I changed mine to the raw voltage inside the cutter for peace of mind.

langmuir-akselCrossFire PRO

1

Jan 28

I wanted to provide everyone with safety information about Primeweld Cut 60 plamsa cutters, and why they are still listed as incompatible on our website here: Plasma Cutter | Langmuir Systems

There are two generations of the Primeweld Cut 60 plasma cutter, and it is easy to identify which generation you have. The first generation does not have a CNC port, whereas the second generation has a CNC port. Both versions are still not supported by Langmuir Systems, and using it is still at your own risk. That said, these risks are drastically different between the two generations.

The first generation has an EMI issue that interrupts the USB communication between the computer and the CNC electronics enclosure. If you have this version, we do not recommend using it at all. If you would still like to try to use it, you will need to take additional steps to ground the plasma cutter’s power supply, or to shield the CNC electronics enclosure and strengthen the USB connection.

The second generation seems to have fixed the EMI issue. However, we have reason to suspect that the CNC port of the second generation has a defective voltage divider. A high percentage of customers who have wired THC through the divided voltage pins have reported issues to us. There have been some reports of receiving a static shock when touching the CNC electronics enclosure, the laptop stand, or the frame of the machine. There have also been reports of damage to VIM boxes and motion control boards after a period of everything working correctly. We have observed voltage from the divided voltage pins of the Primeweld Cut 60 to be within the typical 50:1 ratio range some of the time (if not most of the time), but randomly and suddenly spiking way too high intermittently. This is when we suspect damage to the VIM and motion control board occurs. If you have a second generation Primeweld Cut 60, you can still use it, but we only recommend internally wiring the THC feature for RAW voltage. The torch firing feature can still be wired via the CNC port.

EDIT - JUNE 2022

There is a third generation of the Primeweld Cut 60 that we have determined is completely safe to use with the CrossFire. Primeweld Cut 60 plasma cutters manufactured 2021 to present should be free from the issues that affected the first two generations of this model. Because of this, our plasma cutter compatibility page now has the Primeweld Cut 60 listed in both the incompatible section and the compatible section: pre-2021 is listed as not compatible, 2021 and newer is listed as compatible.

4

Hey thank all 3 of you guys for responding

I reall like the cut 60 it works good maualy and it pretty cheap.

After reading your guys advice im gonna wire it from within and maybe even order the newest version and keep the old one for a back up and hand use