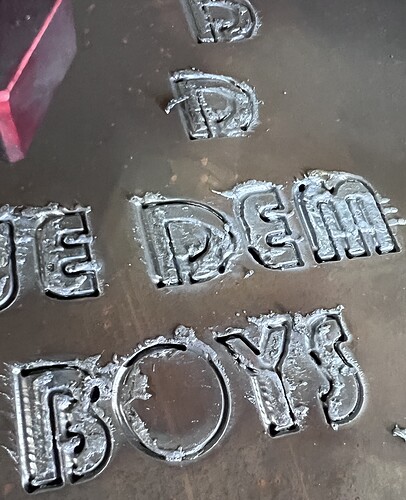

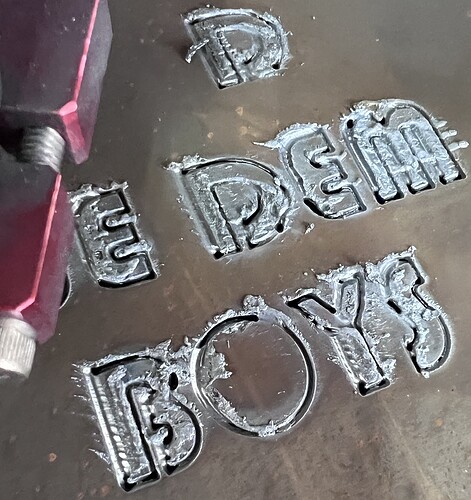

Hey guys! I have attached pictures on here so you guys can see whats going on with my cutting. on mild steel. Getting about 80 psi to the 45 razor weld . Cutting at 114 ipm. Current is was at 25. Pierce delay is .6…… let me know tips i can do. Much appreciated everything was working good before

Has the arc color turned to green? That’s what happens when the electrode burns out and you start burning copper.

1 Consumables are wreaked

2 Cut height is too height

3 Speed too fast

Next time hit stop in firecontrol once you see an issue. You can change out the consumables and go back to cutting from line as long as you don’t re-zero it.

I replaced the consumables when it messed up the first time when cutting SS and it did it again @ds690

Ill cut again tomorrow and see if it turned green i didnt pay attention do that

Looks like you don’t have the work cable on the metal. Also, ipm should be around 60, not 114. It seems like 11 ga. In the pictures

@TinWhisperer i have the thc. Does it need to get calibrated?

THC does not sense whether the cut is good, it only maintains what it senses in the first .25 inches of cut for the voltage reading and then tries to maintain that reading. If you are off in the beginning, it will maintain that mistake.

Try a cut again with a gcode file that you post process. Make a simple drawing like a square. Hit the space bar to interrupt the cut. This will stop the torch and turn it off. You can then get a measurement to see how far off the torch is from the metal. Tin is right (betcha dollars to donuts…I love donuts): it is one of those three things he listed.

The only other thing it could likely be is debris in the consumables blocking air, plasma stream or both. The fact that you had a few moments where it cut thru, I would say you have the work lead attached to the metal.

Yeah the cable is attached to the metal. I even moved it a couple times to make sure it had good contact @ChelanJim @Bigdaddy2166

@TinWhisperer @ChelanJim i replaced the consumables like 3 days ago. I hope they arent the cheap ones. Do you guys know where to get good cheap consumables? I can show you guys a picture of the consumables that are on just to see if they really are messed up

What do you have for moisture control on the air? Did you check the bottom valve on the air compressor?

Please post some nice clear pictures.

A incorrect consumables stack and/or Loose Consumables and/or Water in the air and/or a extra high cut height can wreck consumables in short order.

Applying the correct parameter information to the g code and a solid voltage measure are critical to having the THC work correctly.

Is machine amps set to 45 amps and are you sure that air psi at torch is at least 70-75 psi? THC setting is set to what thickness material is being cut and what the material is,use nominal voltage setting.

Don’t buy cheap consumables. I have a Miller 625 and bought some Taiwan Ernie consumables and they are no good some don’t even attempt work, others half ass work. All original Miller products now.

I haven’t seen anyone suggest it so I will based on personal experience a long time ago…

Did you forget to put the swirl ring on?? ![]()

With a Razorweld Cut45, I’ll use a pierce delay of .8 sec on 11ga @ 45A. If I read correctly, your pierce of .6 @ 25A is way too short.

Like @rat196426 said, turn your Amperage up to 45 & cut speed ~60 - 80. Cut height of .06 and pierce height of .15 work well. Remember - for heights, both processors (SheetCAM / Fusion) add an additional .020 to what you’ve entered.

As far as THC goes, if your pierce is good (thru), and your cut height is good, Smart Voltage will maintain the distance. If not good (incomplete pierce, cut height high / low), THC will maintain the incorrect settings as well.

might help to also provide the gauge of material you’re trying to cut. 25amps seems really low for anything over 18 gauge.

Sorry that’s a oxymoron

Well look who is a literary expert now…

"I can barely use the most basic words " Knick