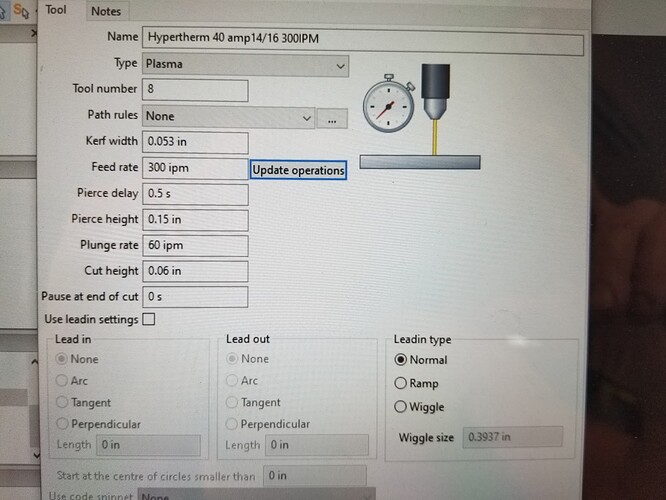

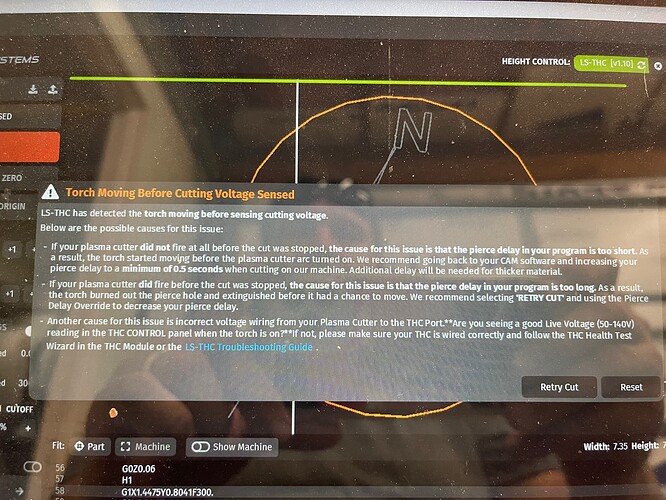

Ok, newbie here…I have been able to download and cut ready cut items from fireshare, now when I run an item thru sheetcam, the torch will make the first cut then stop on the second, the program will not run start to finish on its own, I have to start it at each cut manually…it tell me pierce delay is too long. I have adjusted the suggested setting by hypertherm with a machine torch and have adjusted all the way to zero and still get the same message. I am using a hypertherm 45xp. I have attached my current tool settings…it can’t be this difficult but like I said I am new to this …anyone help me with the settings, do mine look right? or am I way off on setting?

Forgot to mention I am cutting 16 ga cold rolled…

Yep, that’s the error I get… ![]()

try a longer pierce delay. try 1 sec then dial it back from there

I think maybe i found a similar issue in the thread below… i am going to try their suggestion of longer delay after brunch…ugh

I have tried the +4 for the delay that I have read on other threads on here…and have stepped down until I had it set a zero delay and still have the same issue…if I can run a ready cut file with no issue, I would think I would need to know their settings and set mine up the same and it work…

You have written in 1 sec into sheetcam then processed the file and it did not work?

yes, actually that is what hypertherm setting should be for that gauge metal with a machine torch…I have read that there is a delay in the machine and some suggested adding 4 to whatever setting should be, which I have tried and have the same result…

you cutting 26ga ? why so fast ( 300 ipm)

are you clamping to the material?

cutting 16 ga…300ipm is what the hypertherm books says to cut it at…book shows for that gauge of metal cut speed from 249 to 320…no I am not clamping material…it makes the first cut then goes to second cut and does not fire unless I regenerate, then it does second cut, moves to third and does not fire I get the error message, then regenerate again and fire and so on, each cut done manually…I can cut a ready cut , same gauge metal without it stopping or needing to clamped…

clamp to the material

seem very fast for 16 gauge. try best quality setting not production speed settings.

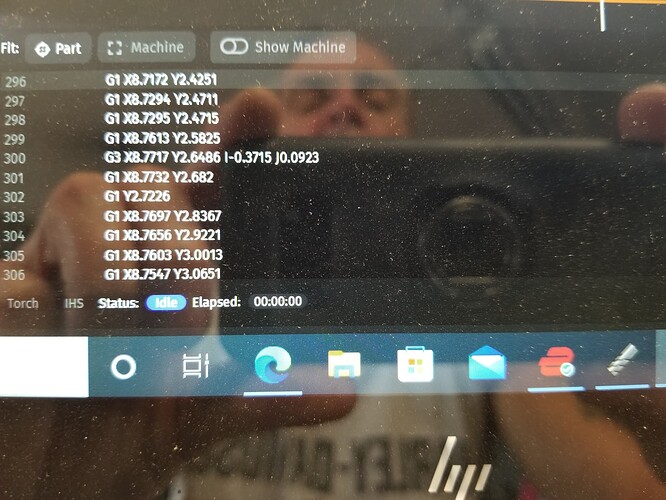

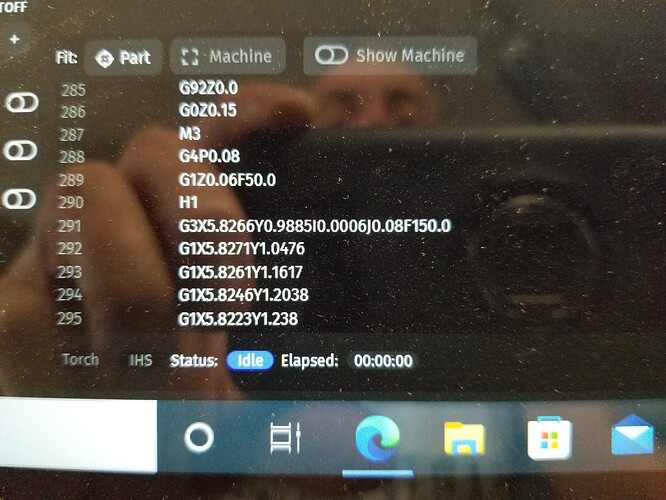

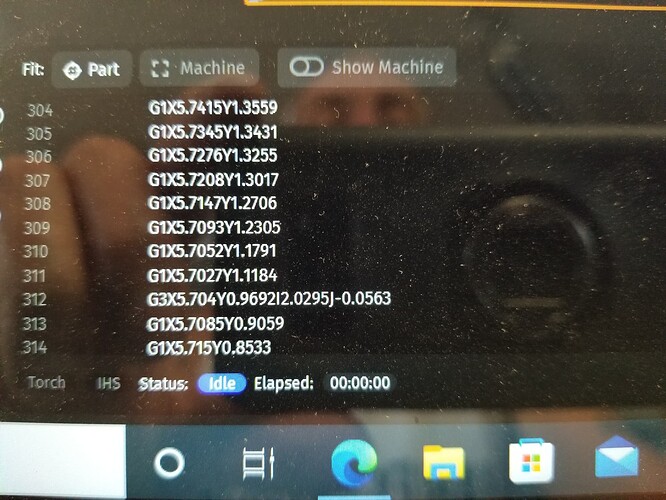

seems like a short pierce delay issue by your description. can you post the first 25 line of your g code of the failed cut.

ok, clamped material, setting at 249ipm best cut quality per Hypertherm settings in book…it made the first cut, i have attached the g code

Still in the same boat with you… mine is clamped to the work piece.

The line 268 of your screen shot is what I would have tried to change, and it looks like you tried exactly what I was going to try, .

4 book setting for pierce delay plus .4 for a total of .8.

The only thing I might try different is to add .5 or .6. Someone suggested in that other thread that adding a range of +.4 to +.6 was the fix.

Line 288 P at .08 ???

try .8sec instead

.8 80% of a second

.08 8% of a second

oh yea, .8, not .08

hypertherm book shows for 16 ga that pierce delay should be .1…I have adjusted to .5, still will not make cuts on it’s own without regenerating the program…I have tried multiple different pierce delay settings with the same result so far…

what you posted above will not work forsure.

setting for pierce delay in tooling on sheet cam is .1??? how is it .08??

.1 would not work either

.5 seconds minimum