ok, ran again at .5…same thing…I have had it set to .8 with the same results…

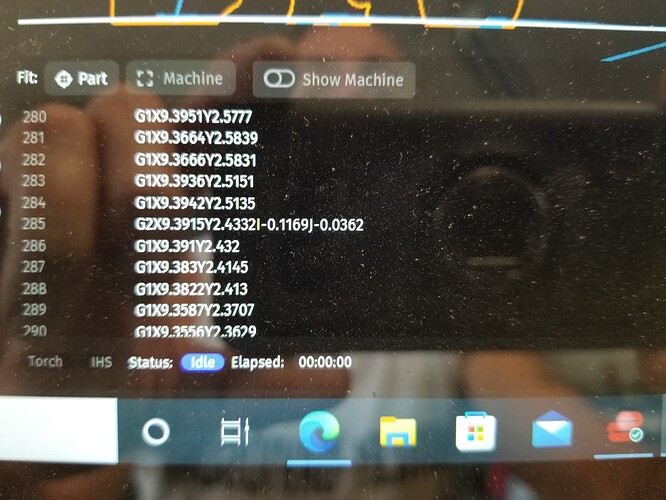

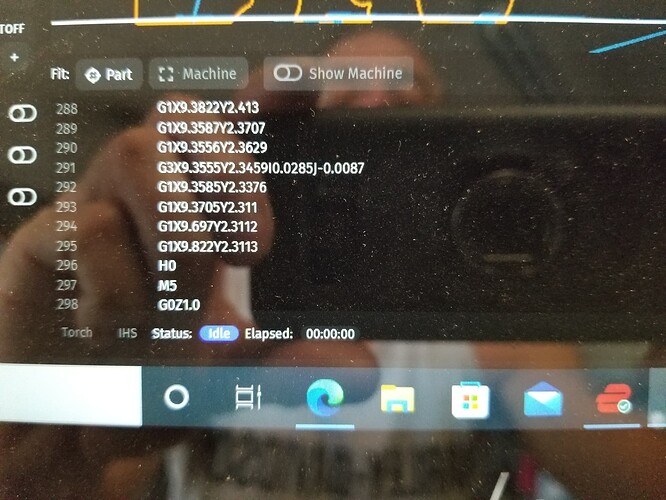

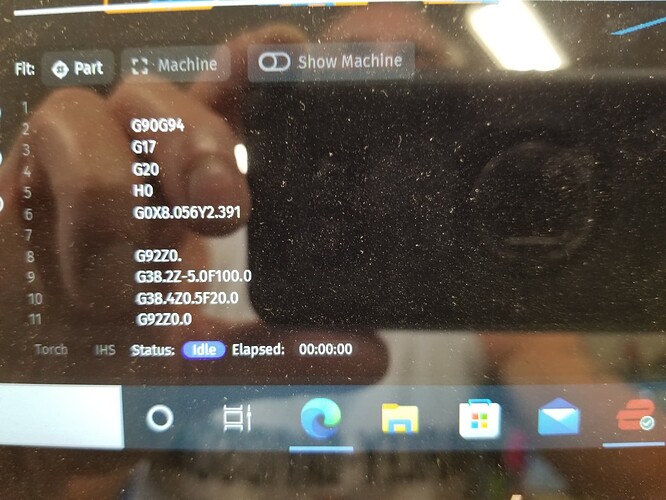

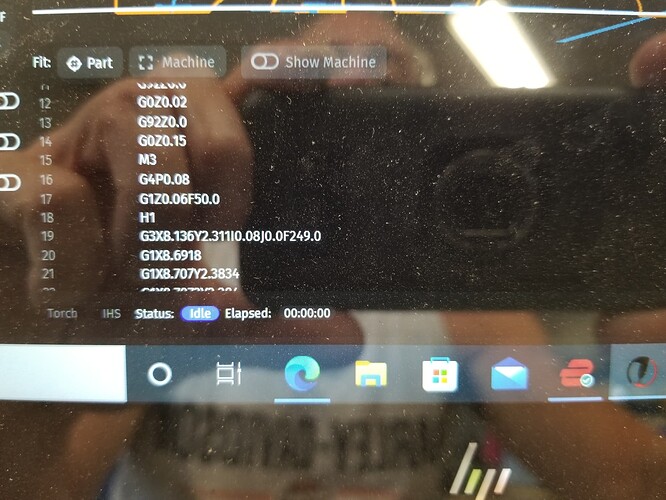

none of those gode pictures show the pierce delay. try the first 20 -25 lines of code

try to post a picture of a line of gcode with P includes or post your NC files to see if the delay is actually long enough in the code you are producing .

It is still showing that reduced Pierce delay at .08"

Some kind of units conversion issue?

Any one of the sheet cam guys out there see anything obvious?

Is the file available? I’ll pull it into sheetcam and see what I get.

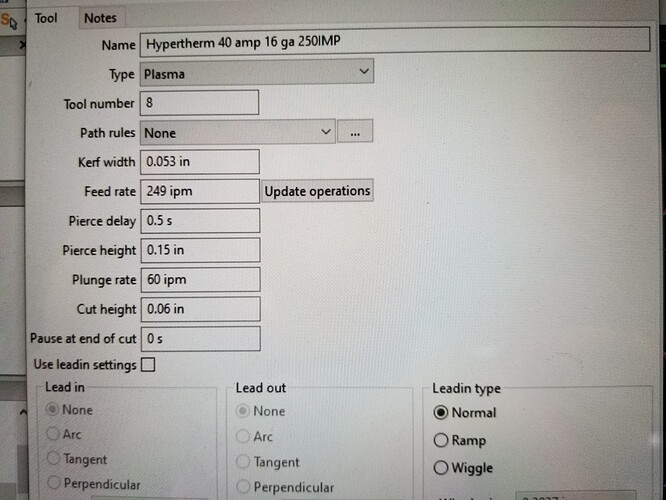

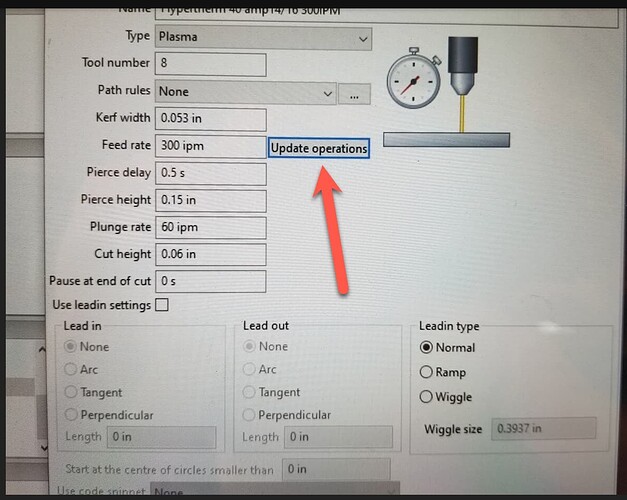

I assume you already have the cutting operation created? If you do are you hitting “update operations” after you change the pierce delay? If you don’t it will not change it in preexisting ops.

Its the delay, I changed mine from .08 to .8 and the program ran fine. I dont know where to fix it in the software, but if you open the file that in a text editor, it is the line from your last screen shot line 16 that said “G4P0.08”. Open the file with a text editor and find each instance of it and delete the zero before the 8

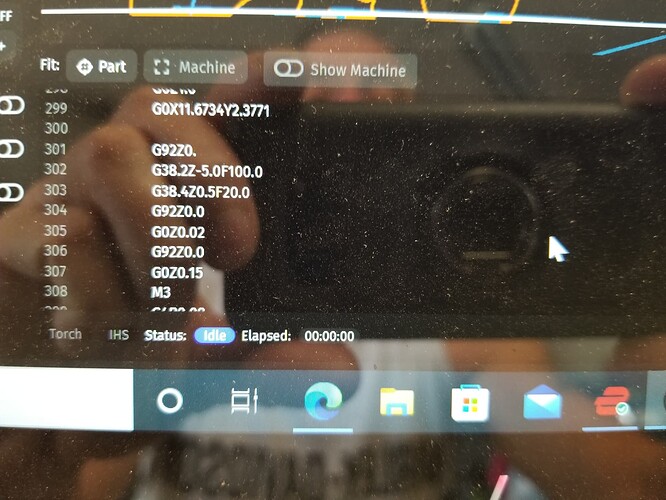

The pierce delay in that code is clearly .08 seconds. If you updated the delay in the tool settings, you should redo the jet cutting operation with the new tool settings.

You can do it in the job file by hitting the update operations button, but I prefer to redo the whole operation.

I have the same setup and was having the exact same problem. The solution I found was that Langmuir controls add .4 seconds of additional delay that is over and above the hypertherm 45xp recommend settings.

Whatever the book tells you for the tip and material that you are cutting, add an additional .4 seconds to the pierce delay and that should get you sorted out.

I found that if I go higher than that I blow out and lose arc and if go below that, I fail to establish the arc.

For what it’s worth… I’m certainly no expert but I receive that error when I forget to attach the ground to the work piece. I have also run into problems when the post process does not write a complete tool path, usually because I ask it to cut something smaller that it can. I run the Hypertherm 45XP book settings and process the the item in Fusion 360. I use 0.1 delay at 320 ipm. I should add that I am using a hand torch and not a machine torch. If your file is from Fireshare, you can tell me which file it is and I’ll process it with Fusion 360 to see if that resolves the issue.