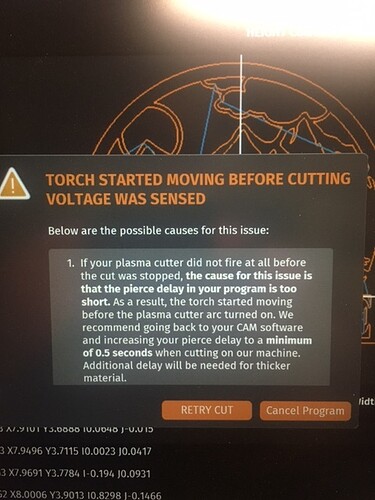

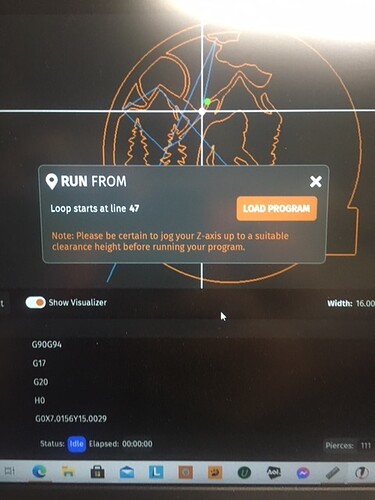

Ok, I am at wits and and losing money!!! Pro with brand new 80 5hp Ingersoll Rand compressor, brand new Lenovo 8 RAM dedicated computer, refrigerated air dryer and manual air filter dryer, Hypertherm xp45 brand new. Here is the problem, post process the file in Sheetcam, load to Fire Control, program begins makes first pierce and cut moves to next pierce, torch moves 1/4 inch and when it is supposed to fire it doesn’t. I then get the alarm box stating my pierce delay is too long or too short. If I clear both alarm boxes that I have picture it will make the second pierce and cut and do the same thing all over again. I can do the whole program by clearing the alarms and hitting start at each new pierce point.

PLEASE READ BEFORE COMMENTING: I ran the pierce delay out to .15 and down to zero in increments, following the alarms trouble shooting advise. NO CHANGE. GOOD AIR, GOOD EARTH, GOOD 16 gauge metal good G code as far as I can tell. Deleted and up loaded all programs several times. Upgraded to the newest Fire Control, installed firmware updates. Separated all of my wires for possible noise interference. Stepper motors are tight and running, Straight test cuts work fine!! It is the second and subsequent pierces that throw it off. NOTHING was changed data wise on my part, it just started doing it. Any help would be greatly appreciated. Langmuir Thomas/Danial anyone.

.15 pierce delay is pretty quick I would up the to .5 at least and go up from there not down.

I took it up to .9, Hypertherm book says .4 for 16 gauge fine cut consumables. What I was trying to convey is that I took the pierce delay from 0 to .9 in small increments and the problem remained. I am going to try with THC off.

GREAT NEWS!!! I went crazy and tweaked it to a 1.0 pierce delay (Hypertherm calls for .4 w/ 16 gauge) and it works as it should, I never thought I would have to go to a whole number to get it to work. Thanks to those that tried. Hopefully smooth sailing again…

I’m not sure how langmuir has firecontrol setup I don’t use it but with some tables you have to double what it says in the book for cnc cutting.

My big table that I use I can get away with 0 delay with no issue but a buddy of mine has a different table then I have and he has to have a longer delay for it to work all depending if it is looking for initial arc or stable arc basically.

Again neither one of these are crossfire tables just my ecxperience with hypertherms and cnc cutting.

I been running at 0.8 at 240 IPM with good results on 16 ga. Same 45XP. Book settings are too short.

either firecontrol or the torch relay has an inherent “delay” so you need to add about .5 secs to whatever book settings are.

I’m at about .47 I think on 16 gauge with fine cuts.

i went from .3 on the original crossfire to .8 on the pro with a primeweld cut60.

Yeah a component changed, I think that and firecontrol are part of it. Once you know what you’re compensating for it’s not a big deal, but the first pierce will always be quicker because the post flow is off. I think…

The Hypertherm charts are for use with their tables. They measure delay from when the arc trigger relay closes, not from when the GCode command to trigger on executes. They’ve got a feedback circuit that allows the table’s controller to know when that is.

The Crossfire measures delay from when the fire command is executed. The relay then closes and the arc lights. But it takes time between the fire command and the relay’s action. That’s why you need to add between .4-.6 seconds (I think that’s the range Langmuir posted here early last year). That extra time takes care of getting to the point where Hypertherm’s delay time will be correct for the actual establishment of the arc.

I had to add .4 to the Hypertherm published delays for every material and thickness. This .4 extra seems to be exactly what FireControl needs to start working with the 45XP

I have the machine torch with fine cut consumables