Hello, I’m Domo from the central VA area. This is my intro so that when I pop into the forum with some whacky question, you won’t be scratching your head in confusion as to who this yahoo is. ![]()

Ha, no but in all seriousness… Middle aged dude who started his post high school career fresh out of vo-tech in the metal fabrication space. Did that for 8yrs in a few capacities, went back to school, been doing comms work for a large Telco for the last 24yrs. I have always had “some” means after getting out of fabrication, but built an 18x32 detached shop about 6yrs ago to make my hobby (eventual side-hustle) shop. I have outfitted it with the ability Stick/MIG/TIG steel and alum, have a 4’ manual sheet roll, RogueFab tubing bender, 4’ (60 ton) Swag brake that I built myself, fast cut saw, plasma, a variety of other misc stuff as well. Not balling, but not bad for a home “hobby” shop.

Been wanting to aquire a plasma table for a number of years, and finally I said screw it. Don’t want to go off on a tangent, but with banks failing due to financial neglegence, inflation reaming a big one from the back side, worldwide political turmoil getting crazier by the day… I went ahead and said screw it. Not much on carrying debt, but I have felt that a CNC table would be a keystone to unlocking the next level in fabrication. I have always used stone-age layout techniques to do EVERYTHING and the Crossfire Pro will be a breath of fresh air, no doubt! I’m prepping my shop and re-arranging to set of a nice protected space for her to live. Happily, I will do a lot of work from the comfirt of my office in the house, then will send to the machine in the shop to git er done! While my CAD experience is limited, I did design a whole 7x16 cargo trailer toy hauler conversion in sketchup, then later executed the build, I am a quick note. I of course plan on messing with different sign builds, but I really want the table to make professional components that I can repeatably/uniformly cut for any fabrication job that I might encounter.

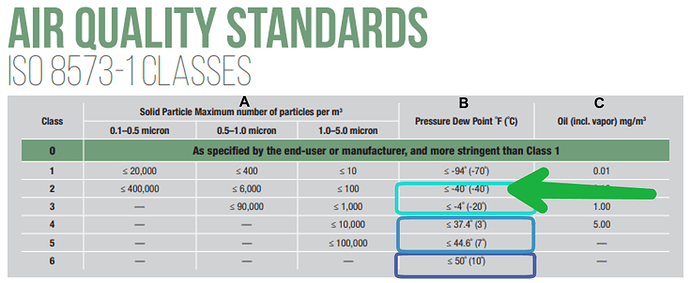

The table is due to arrive on Monday, along with an Everlast 62i, as my current cutter isn’t sufficient. Same with my current compressor which is now a garage compressor. I have a 3.7HP Quincy 60gal in the shop as of yesterday when it was delivered. This noted, I really want to do things right, shorten my learning curve and have a good experience with this, so I am considering my air drying options carefully. Being in VA, we regularly experience 80-90% RH in the summer, so it’s not a matter of “if” I’ll need one… I’ll need a GOOD one! ![]() So, with this in mind and all the reading that I have done, I think that for the sake of my 100A already tapped shop feed, I would like to go passive. Either a custom copper or radiator aftercooler/condeser setup, or maybe a custom dessicant setup, or BOTH. ~ ? The copper system won’t be cheap if I use 1" pipe, so would hope that I could knock it all out with that, but cold hard reality doesn’t yield to emotion, so I am prepared to do a two-stage if need be and run it through dessicant on the output of the aftercooler…

So, with this in mind and all the reading that I have done, I think that for the sake of my 100A already tapped shop feed, I would like to go passive. Either a custom copper or radiator aftercooler/condeser setup, or maybe a custom dessicant setup, or BOTH. ~ ? The copper system won’t be cheap if I use 1" pipe, so would hope that I could knock it all out with that, but cold hard reality doesn’t yield to emotion, so I am prepared to do a two-stage if need be and run it through dessicant on the output of the aftercooler…

Oh, one begging question if somebody knows… The paperwork that I have read so far says that the tables logic/servo controller requires a 20A outlet. Is this correct? I haven’t read anything that actuallly indicates input current, but was wondering if this is actual? I have a 15A outlet next to the tables new home, but can run a 20A feed if this is actually the case.

So there’s my long winded intro. I hope to engage with you all soon as I begin my journey, and hopefully circle back around and share some of my eventual creations. Utility and geometric art are things that excite me and things that I will be focusing on.

Cheers!

-Mike