Here you go:

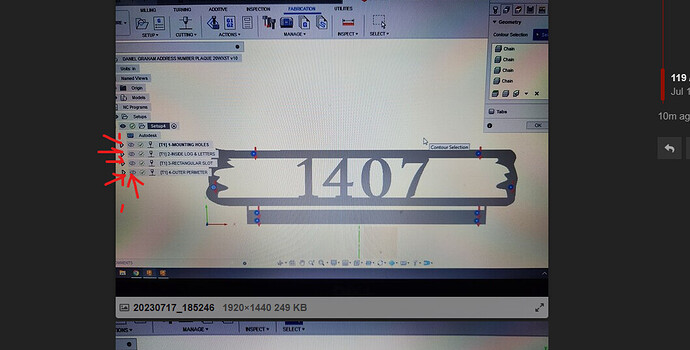

DANIEL GRAHAM ADDRESS NUMBER PLAQUE 20WX5T v12.f3d (583.8 KB)

Its a very cool design…great work!

Well that didn’t work either…

It’s actually an add-on piece for another sign I already made. Guy decided he wanted the address below it.

Try this one. you’ll have to change your plasma cutter in setup and tool in 2D profile i believe

address 1407.f3d (313.9 KB)

I have to make dinner but i can walk through this in a video i show you a few issues i picked up on after.

Don I appreciate the effort and all but I really need to figure out what is causing this and get it fixed. I’ll check out the file Thank you. Something is causing this, everything I have ever cut in the last 5 years I put .250 inch holes or slots in with no problems at all up until the last week or two… Does ridiculous stuff like this on every design I work on since the last big update

I have seen many people are having issues after recent update.

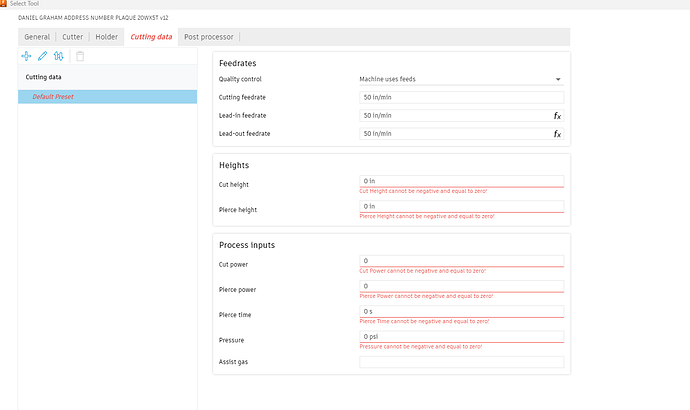

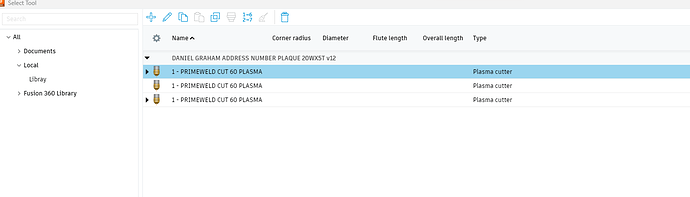

One thing i did see is you have 3 similar cutters but one of them is missing information. Not saying that is your issue but a could other things like your nozzle diameter and kerf width is so different. I’ll have to watch @TinWhisperer video in morning and see what he figures out on this one.

This is how i setup my library so I can just select the steel I plan on cutting and everything is correct for speed and kerf.

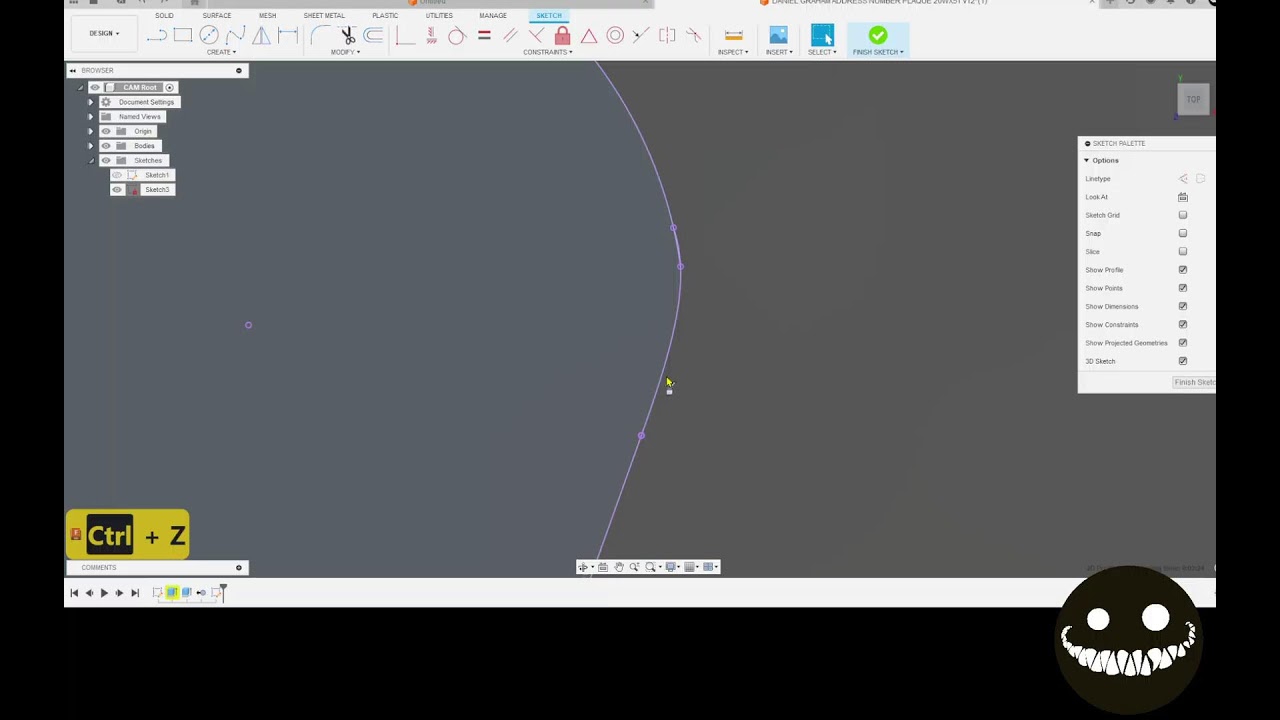

This video shows why so many users hate fusion. Who would think the position of the lead in would cause it not to cut. If your well versed with fusion maybe no big deal if your not this can drive you crazy.

The bad thing is there is no hint of why it wont cut. This video shows even you are perplexed by why it wont work the way you think it should, and you are probably one of the best users on here.

Thanks, Sorry that is all you got out of the video.

That’s not all I got out of the video, I just wanted to point out what’s easy for you makes no sense to the average user.

This has nothing to do with you or your video, your video was good as always.

I think the the thing that has the OP upset is not that you can make his file cuttable, it’s that he can’t.

Is there a way to remove that update in fusion like you can in windows for troubleshooting?

Agreed.

@mdmuss, What operating system are you using on the machine with Fusion 360? The reason I ask is there have been several users with similar complaints as yours (previous success but now not being able to get thru the CAM portion of Fusion 360 after updates in the last 5 months).

Two of those users had Windows 10. If you have Windows 11, then my theory has no credibility. If you are using Windows 10, there is something that is not meshing with Fusion 360 and Windows 10 since these recent updates.

I’m on 10, @ChelanJim, and I do believe they’ve said they would start phasing 10 out, eventually. I think Tin Whisperer told me that; and I think I may have seen something on the Autodesk website about it as well.

FWIW, I do believe I also mentioned picking the lead-in points about 100 posts back; that’s what seems to work for me…

You were one that I was counting with windows 10.

You know that you are unforgettable Casey!?![]()

For what it’s worth, we’re on Win10 as well. While I could not generate a valid tool path from Casey’s file a bit ago, I don’t normally have issues with Fusion. (Potentially due to the fact that 95% of all cuts are structural type items - simple.)

Understood . I am guessing it happened when Fusion 360 became more SheetCAM-esque with the more nuanced drawings. Some of those “enhancements” have thrilled users like me but have created negative consequences for others.

It’ll do just fine for me on non-artwork type projects. A 4” square with 4x 1/4” holes and a radius edges will generate without issue in seconds, with no special tricks. But anything with lots of arcs and line segments bogs down and messes up.

Hello all, I am brand new to the Langmuir and Fusion 360 world. I just got my Crossfire setup(well, almost, the XL Kit is still in transit and I went ahead and put it all together anyway), I got it with every option, Limit Switch, Z-Axis, Water table, ect. I also bought a brand new computer for running Fusion 360, an Asus Tuf 15, running on Windows 11. I am having similar issues.

My dad happened to have a DXF file that he had bought, and I used it to for a test of F360 and the Crossfire. It is a very simple part, nothing complex at all, roughly a triangle with a 3" hole in the middle, and a few 3/8 holes on the top. But Fusion will not recognize the 3/8 holes for anything, and when it creates a tool path, it goes an inch wider then it’s supposed to on the main part and an inch narrower than it should on the hole in the middle. I have tried a lot of different things, but nothing has changed it.

I also made a very simple sign, 3"x5", with basic text in the middle, and all Fusion would do was make a square tool path an inch wider than it should, and not recognize any letters.

Any help would be appreciated.

First, it will speak volumes of you could share the. F3d file from Fusion.

But just off the cuff, it sounds like you have your kerf setting about 1/2 inch larger than it should. The kerf should be somewhere between .03 and .06. it sounds like your kerf is set at .6 inches.

Show us your settings that you used for the tool paths and when posting for the g-code.