Well folks, I’ve had my kit for a good while but life has gotten in the way of my build for a bit. I’m settled in my new digs now though, and the time sitting back in the weeds has given me the chance to benefit from everyone else’s experience on the forum. My new subframe and touch screen mount is starting to take shape. I have a Centroid Acorn6 controller, upgraded mini PC, bigger control enclosure, stainless shower drains and a bunch of other stuff. I’ll try my best to document the journey. Here’s the first glimpse of what I have going on at the moment.

He is a good guy to learn from.

He’s an artist when it comes to aluminum. I’m hoping powder coating will hid a lot of my sins.

Jb weld the sins then powder coat. Jb weld is a powder coaters Bondo.

agree with that

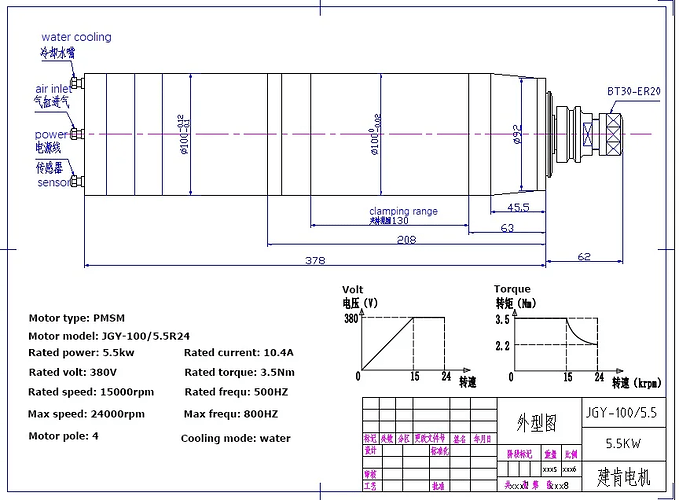

Ryan and Alex inspired me to order one of these today:

5.5 kW ATC high torque permanent magnet synchronous motor. Hopefully their wine rack tooling dispenser designs will be all scienced out by the tiime I cross that bridge.

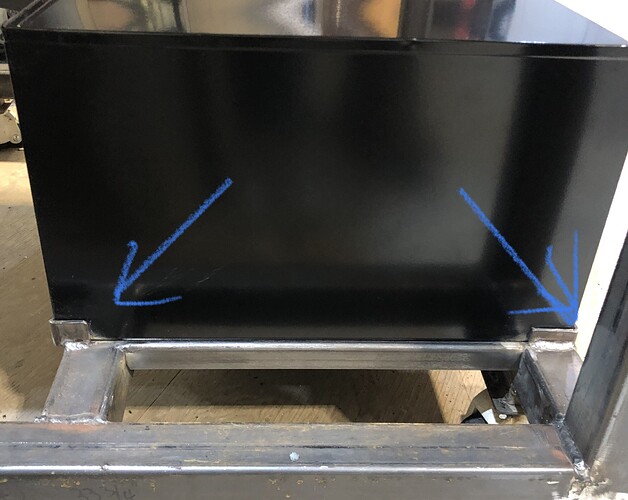

I needed to make a base for my two tool boxes so they stacked properly. I used some of the square tubing and corner fittings that shipped with my MR-1.

Here’s how it looked after screwing it down with sheet metal screws to the bottoms of the top tool box and stacking them.

Now I have to figure out how to mount the new control box. It’s going to have a Centroid Acorn six controller, wireless pendant, and Clearpath servo motors.

Are you putting the VFD (servo drive) into that box too, or keeping the original one for the VFD?

Since you are replacing all of that you may also want to consider moving to 48v PSU vs 36v (check what Clearpath recommends of course). Moving to 48v PSU make a big improvement on my stepper-based machine.

I remember you saying higher voltage supplies are better in one your build posts Alex so I’m actually planning on using the IPC 75VDC power supplies that clearpath supplies:

The spindle is a permanent magnet synchronous style motor so it requires an inverter to work in my 220V single phase garage. The manufacturer supplied the inverter with the spindle pre-programmed. I have 20,000 HP synchronous motors driving compressors at my work but my Sparky buddies deal with them. I just look after the compressors. I’m planning on plying my buddies with beer to help me deal with that inverter. Fortunately in Canada, you could probably get your neighbors to build you a nice two car garage if you supplied enough beer.

I don’t think the inverter will fit in the new control enclosure. Likely best it goes into its own box anyway. I’m guessing an inductive load like that will make the control board / low voltage dc circuits go nuts. Feedback from any forum members in the know on that topic welcomed.

Well, the stock control has it in the same enclosure and seems to work fine.

I reused the stock enclosure and have my VFD in there and it hasn’t been an issue at all. I do use a VFD with integrated EMI filter. I kept the stock layout (VFD at the bottom, control board in the middle, stepper drivers at the top).

I think that inverter my spindle comes with converts my single phase 220v into three phase and acts as the VFD as well. At least that’s what the supplier said. I don’t know if that makes EMF interference worse for the low voltage signals or not but I suspect it will. I’d love to put the inverter in the same enclosure with everything else but my other issue is it looks really big in the photos. It was supposed to show up today but UPS is brutal where I live. A carrier pigeon would have been a better option.

Well the new spindle showed up along with the inverter. As I suspected from the supplier’s website photos it’s big. Too big for the oversized enclosure I got in fact. Plan B: the inverter is getting it’s own home.

The new spindle is awesome. Very compact for 5.5 kW and the torque it produces. The colour of the mount it came with hurts my eyes. Plus all the critical mounting surfaces are powder coated with that god awful gold colour. Gonna have to address that at some point I’m guessing.