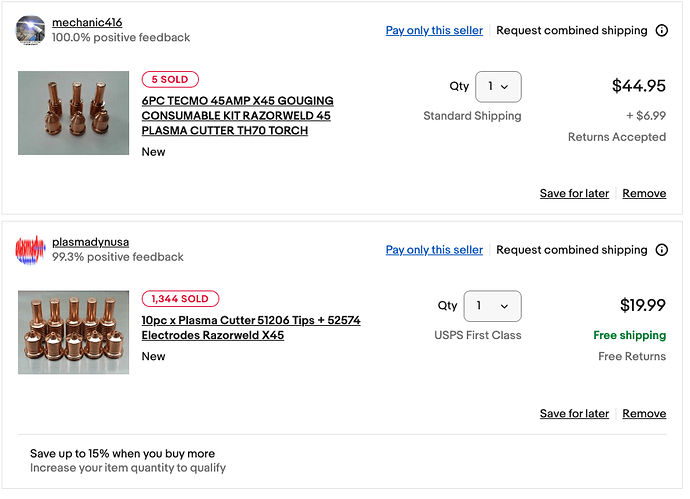

ordered some consumables… those three pairs better be worth the extra $32 and two pairs of consumables short…

They are. I use George’s consumables now and have been very happy with them.

out of curiosity, are you only replacing the parts pictured above normally or the shield and plastic swirl thing too?

Normally, just the electrode and nozzle. We do have an extra swirl ring and nozzle on hand if needed. (I haven’t had to change those in quite a while.)

I usually set the feed rate in the operation, not the machine options. I think either works though. For some cuts, may want different speeds.

I prefer to have my feed rates set by the tool defaults. (A tool defined for each material thickness.) That way the speed setting I’ve gathered apply to the material I’m cutting. There’s nothing wrong with changing your speeds when you set the operation, I just feel this is an extra step.

I saw that George suggested to another member if it is possible that the swirl ring was subjected to an abusive amount of heat/amperage (such as using higher than rated amperage or the electrode went into total meltdown) you should probably replace the swirl ring even if it looks good. Otherwise you inspect it and if there are no cracks or visible damage, it is probably fine.

I have replaced the shield and swirl ring as a test with a new batch of electrode/nozzle set to see if it made any difference. If no difference, replace with the old shield and swirl ring.

mine is out on my desk right now. It looks fine. I am going to clean the parts, reinstall, and rerun the job with some slight changes in the code and see if it will burn or keep getting the THC error.

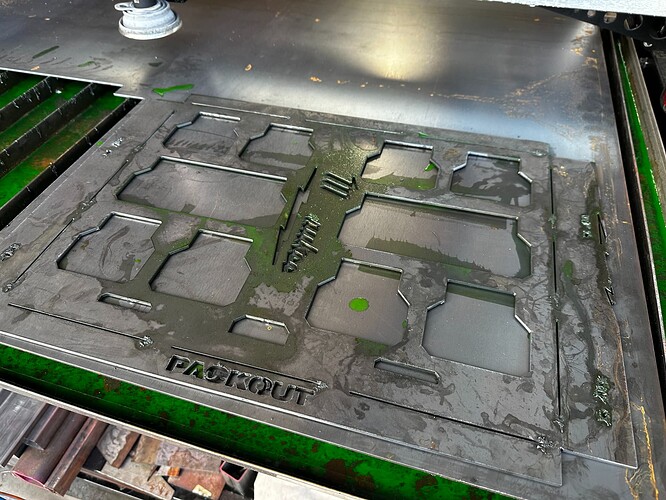

well, damn it wasn’t consumables or settings. It was the Milwaukee logo that was hanging it up.

hypotheses now:

water level too high causing splash back that interrupts the THC and torch firing

something about the logo design cut that causes the problem

tests:

i removed the logo from the design and it cut perfectly

things i learned from the prototype design:

my bend measurements are off by 0.341in on width, a critical dimension so i will have to fix the design for my cabinet configuration. it should work for others.

also, I need to fix the position of the Milwaukee system holes as the riser bumps need more clearance.

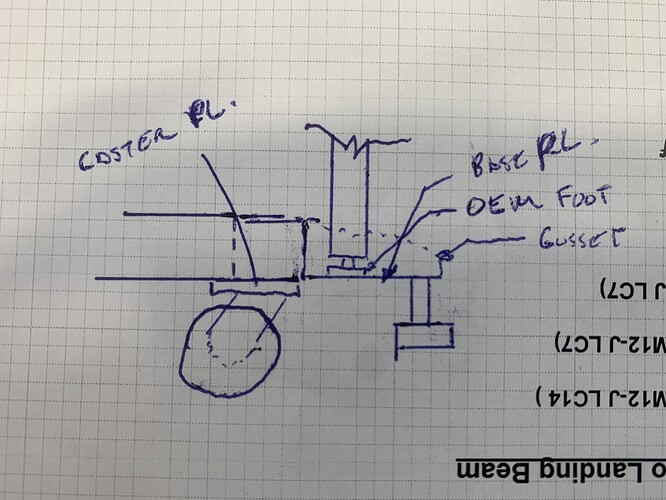

I’m curious if you have a photo with the table mounted on the base? Wondering if you legs are on toe of caster plates, or on the base plate you designed.

My base is all welded mild steel frame. I use the oem bolts from the CFP feet to bolt the legs to the frame. It is sized exact fit to the CFP frame. I posted pics here somewhere up there in this thread.

My caster design came out flawed because the ¾" bolts interfere with the casters rotation. Doesn’t really matter because I never move the table. If I did it over again I would just use those casters that have the integrated rubber foot that is on a threaded bolt with a ratchet lever.

That’s what I was thinking, thanks.

Hoping to start cutting next week(the first project is your base setup)…

What CAD program is that? all the notes on the bottom right are upside down

It’s called open corner scratch. ![]()

Well I sure hope its cheaper than Fusion’s paid subscription.

Well after a lot of struggling, I ran the cutter for the first time today and it ended in success. I was not able to import your dxf files to fusion so had to open in cad, get dims and recreate components in fusion, then learn how to generate the dxf/cn files from scratch… that was yesterdays task… this morning was ready to cut. a few trial and errors but once I turned off the THC and manually set it all worked out. still trouble shooting the THC issue. First thing that was hindering was the laptop charger. not showing voltage when firing, unplugged and back in business. THC had to be dissabled as it was going in the wrong direction(UP) when it was trying to reduce height to material… I see lots of threads about this but none apply to my setup. It’s a ProCut 80A, which is the equivalent to the RazorCut 80 so there shouldn’t be a n issue with the Trigger/DVI ports.

Happy with the cuts.

cool, but why are you in my build thread? lol

dunno… I replied to 72pony from my original post to him… you replied to that post as well.