Using the compressed air in the enclosed cabinet is a flying metal tornado. The wash down works many times better. Clean up is also much easier. The small pump I’m using only has a 3/8 line. It’s not like washing your truck type pressure.

That flood coolant additive also dries sticky, so compressed air will not remove the chips that have had a chance to dry. It’s like drops of syrup.

I know LS recommends the Universal Lubricoolant, but has anybody had experience with any other product(s) that aren’t so annoyingly sticky?

Ahhh, that makes sense. I’m adding a shallow well pump for higher PSI compared to the standard pump so I suppose I should add a washdown hose inline as well!

i use band aid by lenox in all my stuff. doesn’t seem to be very sticky

Probe Lead Cap

Here is an STL file to print a cap for the probe lead that sits on top of the spindle shroud. Not a lot of chips and fluid make it up there, but I thought better to have it capped off when not in use.

Change extension to stl.

Knurled Probe Cap.nc (2.2 MB)

The 3-prong on the left looks like a 220 30amp. I thought the spec was 220 20amp? I wired 220 20amp receptacle. Do I need to replace my breaker and run 30amp wire?

Found my “condom”, like yours, in my Ham Radio gear. Rubbery booties for Anderson power pole connectors are very similar to that and also have a snug fit.

–

Well if you misplace it, just turn off the lights ![]()

If you have the same outlets as I do, this works nicely.

That’s a 120 plug, unless you wired your outlet to be 240.

No its right ( no disrespect). 240v 20amp max. I have two of those outlets in my shop.

The 120v version is opposite vertical prong. I mistakenly.ordered that first, a 5-20p is 120v. After my mistake, the 6-20p is correct. It was easy to get confused for sure!

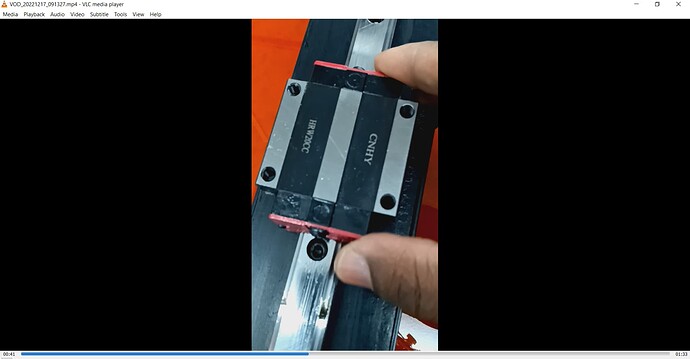

Stiff Y-axis linear bearing… I’m installing the Y-axis linear rails and bearings and I notice that one of the linear bearings doesn’t slide smooth like the others. Might this be solved with a zerk fitting and grease gun, or should it be replaced? Anyone else run into this?

Image of the stiff Linear bearing.

It’s not uncommon for some bearings to be a little tighter than others, it shouldn’t cause any issues. Sometimes the recirculation circuits and ball bearing fits are just a smidge tighter than others. I would recommend proceeding with assembly and running the machine. If that bearing gives you any issues it’s very easy to swap a new one on after the fact.

Thanks, really appreciate the response being that it’s Saturday and all. ![]() Just fyi, I wouldn’t describe this as feeling tight. More like grindy or gritty. I’m going to try to use a zerk fitting and add some grease… then continue the assembly. Oh, here’s a question… does it matter which side of the bearing you lube, being that the inside screw won’t be accessible once the machine is further assembled.

Just fyi, I wouldn’t describe this as feeling tight. More like grindy or gritty. I’m going to try to use a zerk fitting and add some grease… then continue the assembly. Oh, here’s a question… does it matter which side of the bearing you lube, being that the inside screw won’t be accessible once the machine is further assembled.

No you can insert grease from either side. To add to mike’s point, sometimes the notchiness is due to the balls leaving the raceway and entering the recirculation passage. Usually smooths out over time.

The key thing is that there isn’t any lash in the bearing, that’s most important.

Thanks again for the help/input. Shot some lube in it… feels much better…no more grind or catching. ![]()