It’s what I have to use until I can get some toe clamps made unfortunately. Backed feeds way down and got it done at least. Still really rough on the cam side of things for me, got some learning to do

Lookin good!

what torque are using when bolting down the vise or the hold downs?

30~35 lbs per their instructions. To hold work piece. 20 lbs to anchor the vise down to the base plate.

in lbs im assuming… hmm I gotta look through the videos again. I think I missed that. Thanks!

10 lubed, 14 foot lbs dry. for 1/4-20 socket cap allens, 12 ftlbs dry for grade 8. This is for standard fastener installs, 20 inch pounds is really loose but maybe. 20ft pounds might break a 1.4-20 bolt.

20 - 30 ft lbs not to exceed 35 ft lbs. * For the bolts mounting the vise to a fixture plate, please see our Fixture Plate FAQ for recommended torque specs. This varies depending on fixture plate material and hole pattern.

- For the 7/16" clamping fasteners on both steel and aluminum vises we recommend 20 ft-lbs [27 N-m] for general use. Necessary clamping torque is dependent on a) the use case and needed clamping force and b) how much the jaw is ‘preloaded’ (i.e. how far the two clamping screws are backed out before setting the position of the adjustable base). Anywhere from 10-30 ft-lbs [14-40 N-m] is appropriate, but ***do not exceed 35 ft-lbs [47 N-m].***How to Use The Saunders Machine Works Mod Vise System - YouTube

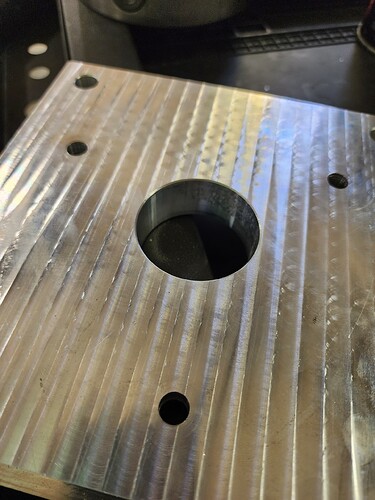

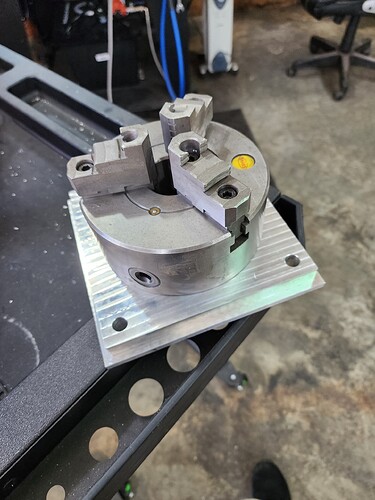

Made this this morning. This is so I could bolt down

a 6 inch lathe chuck to base plate for round parts.

I ordered a low profile chuck to keep the height down.

Still in development stages…

Threads came out awesome. Hell the whole cap looks great.

Were you grinding your teeth while threading it? ![]()

Thanks, the finish is better than the picture lets on. Oops, I forgot to mention the threading was done in the lathe. It’s a 11.5 tpi npt, and I didn’t want to attempt that as my first ever thread milling operation.

MGA twin cam?

My neighbor had one when I was little. I remember it well. He worked on it every weekend. I remember that to open the doors you would reach inside and pull a cable that was strung across the inside of the doors.

Factory stuff…

Yes sir, not mine though

These are some amazing projects. I have a ton of learnin to do ![]()

Guess I should clarify I have the Langmuir vise. I’m guessing the torque specs would still be the same since it’s still an aluminum base

I agree. 1/4-20 bolt is still threaded into T6 aluminum.