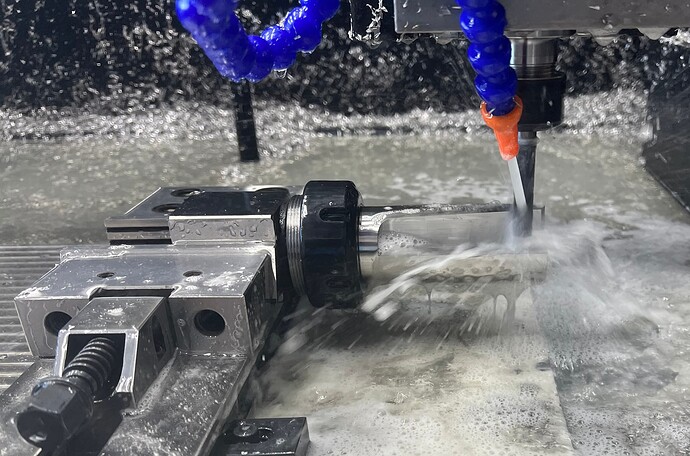

First Stainless Chips Flying

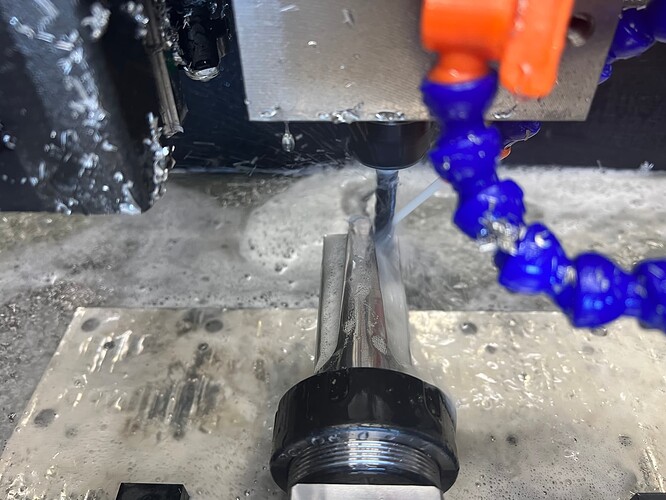

Second Project In Progress

Knight for a chess set. Started making chess pieces out of stainless and brass on the lathe. Of course the knight is the only piece that can’t really be done on the lathe and look right, so I came up with this simple design.

First op is clearing material from the side and then rotating 90° for the second op cutting the horse profile.

First op has been running for over 3 hours now with another hour to go:

One of the main reasons the operation takes so long is that the Personal Use license for Fusion 360 limits what could be rapid movement in the tool path to the cutting feed rate which in this case is 8.3 IPM. So a lot of slow jogs moving to start the next cut. Another reason, that @TinWhisperer might be able to help with, while defining the stock in the cam setup, it would not allow a cylinder to be aligned with a horizontal work coordinate, the cylinder would remain vertical and not align with the horizontal body, but square stock would. Which means a lot of cutting air due the tool path cutting away corner that are not there on the round stock.

Stock holding: ER40 Collet Block in low profile vice

End Mill: Lakeshore 3/8" Variable 5 Flute for Stainless

SFM: 180

IPT: 0.0009"

WOC: 0.0375"

DOC: 0.100"

RPM: 1833

Feed Rate: 8.3 IPM

I’ll post some video later. Probably after I break something.