I’m have issues with using razercut 45x and it’s misfiring and not cutting all the way through. I believe it’s my consumables.ive tried a new plasma cutter new torch and new ground clamp and new consumables still same thing only thing that will change is if I loosen my shield it will not misfire but still not cutting all the way through .The air pressure is at 70 while running .The consumable I purchased from langmuir where supposed to be for razorweld 45x but package says hyp 45 machine .Not sure what to try

I believe you were sent the wrong consumables. Please share a photo of what you were sent and what you are trying.

Also check the cut height with feeler gauge. If you are not cutting all the way thru the metal, there is either:

- not a good connection with the work lead from cutter to metal,

- insufficient air (perhaps your internal regulator of cutter is at fault)

- wrong or defective consumables or how they are installed

- debris in the torch head or plugged holes in the shield or torch

- defective cutter

- torch is too far away from metal or moving too quickly

- initial pierce failed to clear a path…What is the thickness of metal you are trying to cut???

Please show photos of your setup

Are you using a hand torch or machine torch? How is it mounted “pictures" will help.

This is the consumables

The new plasma cutter

And my gun

The cut heights I’ve tried are .059 to .062 1/8 steel and tried several different speeds no luck only loosening tip changes anything on old wand and new wand I use IHS and THC tried turning THC off and get same result

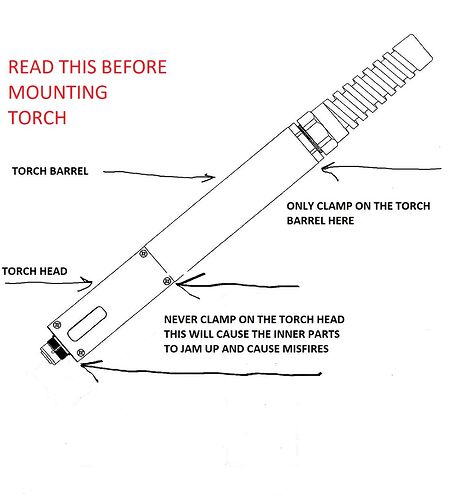

First those consumables are not Hypertherm. They are Chinese copy’s. Also your torch is mounted incorrectly.

First those consumables are not Hypertherm. They are Chinese copy’s

where do i get the good ones

Also your torch is mounted incorrectly.

i ill remount tomorrow

“Good” ones would just be a set of genuine consumables.

They’re labeled as such as they’re based off the old T45 nomenclature. Hypertherm has long stopped producing them and doesn’t care to sue over that old tech which is why many companies have copied them.

Read up on the whole Hypertherm vs ATTC if you’re bored.

Anyway, you can still find new old stock T45 consumables out there.

T45 consumables will fit the razercut 45 ?

I did not say that exactly.

Just simply pointing out the consumables you posted a picture of, more specifically the “HYP45” descriptor, are based off of the old T45 Hypertherm consumables.

Whether they fit your torch or not is not for me to answer. But since you asked about “good ones”, I just wanted to share what good ones are.

Also your torch is mounted incorrectly

It has to be clamped in that area because the of the dimensions of the mount.If I move it all the way down it will still clamp the head

No, it is not. It can’t be clamped in that area of the torch. 1000 people have the same setup.

Having it clamp there is squeezing the pilot mechanism. Move the clamp up.

Where is the work clamp? It must be on the metal you’re cutting. It looks like a connection issue, either on the clamp or at the machine end.

Could you send us your cutting data?

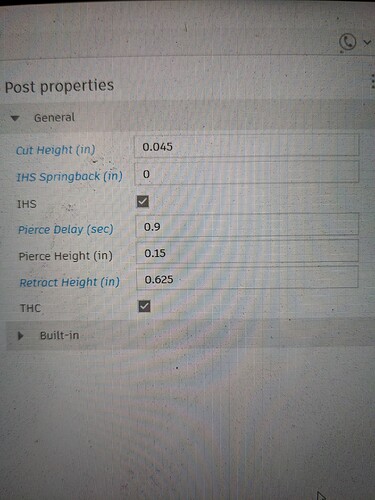

Clamp is on the metal.I measureed my real cut height to be .1 but it’s set to .063

Set Fusion cut height to .045 and the backlash to 0. Try it again.

Try what BigDaddy says.

Another idea is to turn off the IHS and the THC and set the torch manually. I still suspect that the torch to metal height is too high.

I changed to .045 and it cut through but had to knock it out .What could be wrong it was working fine at .062 what is causing it not to go all the down to where it suppose to

Could you send us your settings and what you are cutting? I would check the connection at the plasma cutter work clamp.

I have not seen anywhere in your replies that you have actually measured your cut heights. Don’t trust that just because you set 0.062 that the torch is actually setting at 0.062.

Have you measured it?