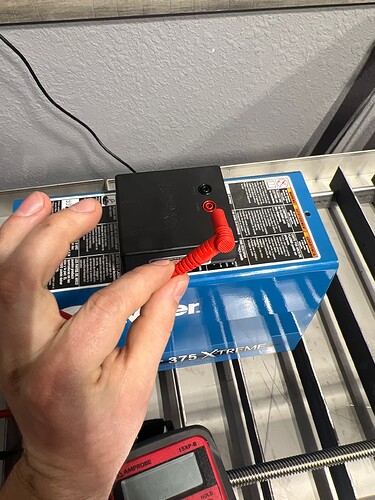

Hey guys, Beginner Cutter here. Trying to get my crossfire pro setup with my Crossfire Pro. I looked at a couple threads on here reguarding setting up my THC. I was wondering for people who have done this before, what lug did you hook up your red lead. I have two options, torch white or torch red. The posts I have seen suprisingly have been all different. Im assuming over the years they changed orientation. If anyone has a clear shot inside of their box to show the writing behind the lug displaying their connections. As you may already know I am running the THC Raw setup. As you can see my negative cable from the THC box is on the lug all the way to the right labeled work lead (-). Once again to reiterate I need to verify the connection from the THC Box Red Wire to the machine. Thanks! any input is greatly appreciated

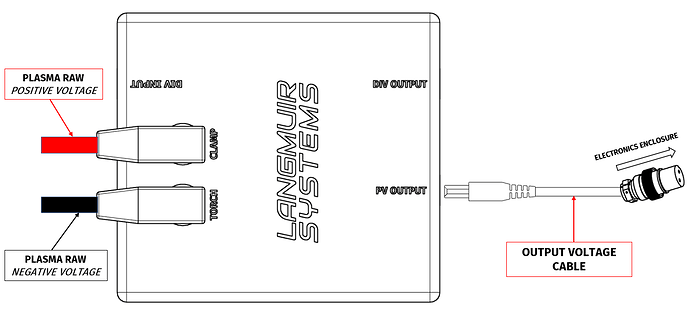

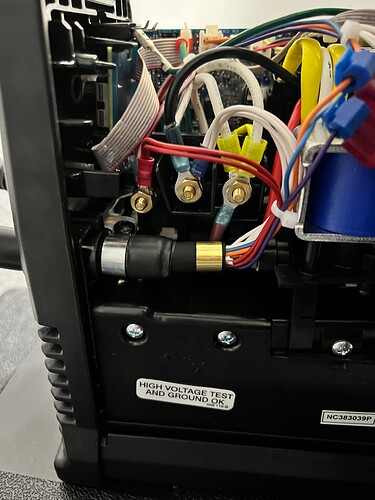

The red wire from the THC will connect to the far right terminal also known as TE-4 in the Miller manual .

The black wire from the THC will connect to the middle terminal known as TE-3 in the manual.

(Obviously electrical work is at your own risk)

Welcome to The Forum.

Thanks for the input! do you know on your machine if the lugs are labeled? the reason I ask is because the Raw Voltage instructions say that the black wire goes to the negative. The lug all the way to the right is the negative.

No they are not labeled and some machines have those last two lugs reversed depending on what torch was installed.

The red wire from the THC does go to the positive side of the plasma torch which is the work (ground) clamp . The terminal on the far right if you trace those wires you’ll see that they’ll run over to where the work clamp is attached in the machine.

The middle lug feeds power to the electrode of the plasma torch (lots of small white wires) and is the negative side of the power supply. From here a black wire is run to the torch height control box (vim)

The electrode is the negative side of the power supply.

A plasma torch is a constant current electrode negative power supply

The diagram of the voltage input module above is correct

Thank you! I am still very new to plasma, I was going off my knowledge in reguards to welding. This is incredibly helpful!

@nickyrc1 you will find that is a character defect of @TinWhisperer !!! lol!!! he is exceptionally helpful!

Hey, So I hooked up the wires to the spectrum 375. I tried to do a thc test and the torch will not fire. Any tips?

Where are the trigger wires hooked up to?

I think they are the purple and orange wires.

there are topics on the trigger wiring… search above…

Edit ’ I see them in the photo above

can you hear the relay click inside the Langmuir electronic enclosure when you fire the torch?

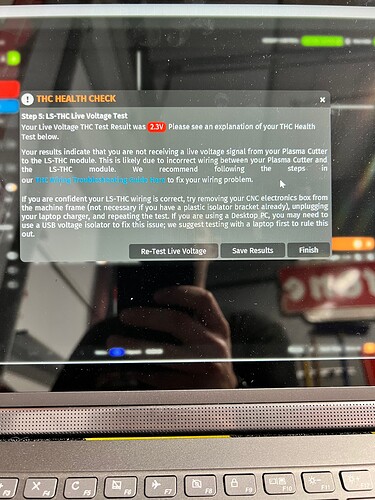

No I cannot. I also checked the voltage when the torch is running manually and it falls roughly at 148- 153. I know it says reccomended is 90-150v. There is no continuity between the black (torch) and Red (Work Lead) Wires. I am pulling 6-7 volts with the torch bot running from those wires as well. I also checked the USB & Gantry for continuity and did not get any Either. I tried to run a simple program as well from fire share and it kept stopping mid run. When I ran the THC Test it said my voltage was 2.0. I reset the system and this time it fired. No wires were touched

Edit, I can hear the click. I was not close enough to the box.

unplug your laptop power during the cut. and do a simple straight line cut using fire control .

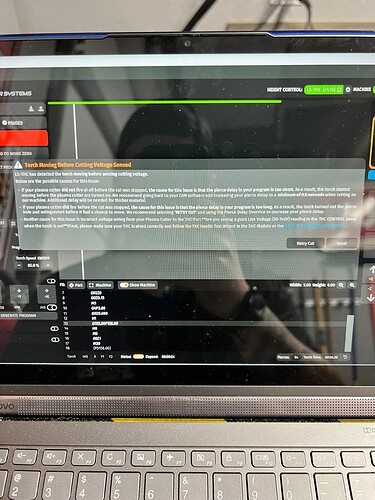

It will not complete the cut. It gives me this message.

did it fire?

yes once it moves direction it basically dies.

what material are you cutting? 3 second pierce delay is a lot.

Where is your work clamp ( ground clamp)? on the material?

I tried a bunch of different intervals. I am cutting 16-gauge mild steel as a test piece. The book recommends 158ipm for this size material cutting at 20AMPS. So I figured they were good benchmarks. What would you recommend I run for pierce delay, just to rule that out. This is my first time actually live operating the machine. At this moment I am trying to ensure the machine is hooked up correctly.