Been there, done that…forgot the work lead clamp more times that I will admit…yes - a lot of variables to keep up with! But it’s sooo nice when a cut comes out just how you wanted it!

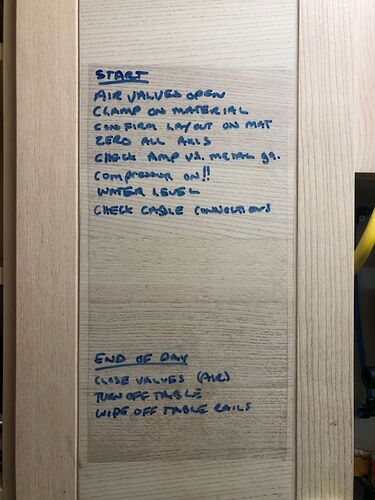

we all do…especially as we get older…here is what I have done to help my man-brain…I use a dry erase board to make notes

This is awesome👌

I ran the 40a tip and cranked the machine down to 30amps… cutting 16ga… and it worked great… cleaner cuts then i could get with the 30a tip. Thanks again for the advice👍

Ive got a odd issue I think. running my 625 on a pro table now. long machine torch, 40amp tip and machine tip. (have the THC and I have the upgraded interface on the 625 for controller) . pierce height around 0.09 and cutting around 0.05. 11ga steel. 110psi, 40 amps, 140ipm.

I used to run 0.4 pierce time on the old crossfire using. inkscape/sheetcam/mach3/ combo.

using inkscape/sheetcam/firecontrol with my new pro, I have to keep my pierce time above 1.3 seconds to not get the torch moved before torch firing message warning to use at least 0.5 pierce times. you can imagine what 1.3 does on fine detail work…

any thoughts on what to check or other settings?

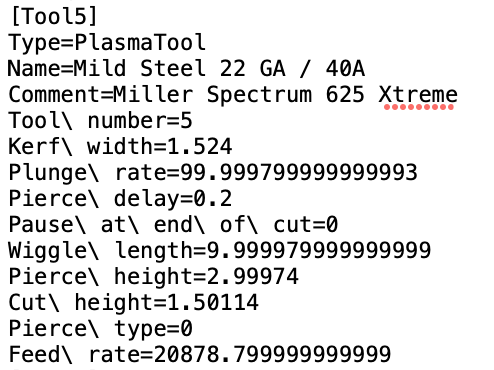

I’ve created a pdf of @James5 tools / cut sheet he posted here 625 cut sheet

Before I post it, there is one thing I need some clarification on regarding the “Feed Rate” data field. James5, your Feed Rate numbers, which I assumed was the cut speed (IPM), have me confused. For example, 22ga Mild steel at 40A has a feed rate of 20878.8 . What exactly is that number? I thought it was mm/min but when I converted it to IPM I get 822 IPM… These machines don’t run that fast, maxing out at 300IPM. Can you clarify?

I’m currently using an older 625 extreme from around 2013 or so with no usb and an XT40T hand torch with the Miller Plasma Drag Shield 204323, Miller Plasma Tip 40 Amp Standard 204325 and Miller electrode 192047.

I’m curious about using the extended electrodes with the deflector that have no drag shield. I believe the drag shield adds a few mm of material between the tip and your work piece requiring the pierce/cut height be adjusted accordingly. So if you send me some cut info, add what torch, tips and electrodes you are using

My feed rate numbers came from the Miller owners manual. It’s not 20878.8 - not sure where you got that from…actually NM- I just checked the manual - that’s mm/min. Something must have converted it - I used IPM, but when you imported or viewed it it must have changed. The IPM equivalent is 822 IPM. You are right about the 300 IPM limit - so anything over 300 IPM from the manual should be set to 300 IPM. I usually back the power down a little and slow the rate to 225-250 IPM on 22ga, but you’ll need to do some experimentation to find the sweet spot for the metal you are cutting. Hope that helps!

Ahh perfect.

Here’s what your file shows:

I’m also guessing all those other numbers (kerf, heights) are mm as well.

I’ll run down the list and see what the conversion gives me and make the adjustments.

That may be how sheetcam stores the data - in metric. The software developers are based in Great Britain, I believe. I typed it in using IPM, and use imperial, so maybe check settings to see if you are displaying in metric? Not sure.

Here’s a link to the manual if you want to use that as a reference instead:

o264267c_mil (millerwelds.com)

The info comes from page 28 (24 in the print version).