Is there a combination of amperage and speed that allows the system to mark parts rather than cut them out? Like part numbers, or text of some minimal size, etc.

The hypertherm 45xp has marking capability.

Check out this topic where it was discussed a little bit.

I am wondering if one turns the current way down on, say, a razorweld 45, would you be able to mark with it?

yes there’s tutorials on youtube for the set up search here using the keyword “peck” you’l find links.

Is there a way to program 2 stages in one file? 1 to mark then pause allowing me to change settings and consumables and then resume or start the second stage to cut? I am fearful or shall I say dreading having to do 2 files one for marking and one for cutting and having to line them up properly.

Yes. There is a way to do that.

I have used two different cut nozzles in the same program before with a long pause so I could stop it to change the consumables.

As long as they use the same stock box point “origin” then they should line up perfect.

I did order a box of Hypertherm markings consumables but I haven’t had the time or project to use them on yet.

I’d like to figure this out, I have a design that a client wants to have their logo on but it is either to small for my plasma to cut or I am doing something wrong in the post processing in F360. Can I PM it to you @TinWhisperer to have you see if I’m doing something wrong? If not I want to be able to mark it instead of cut it.

sure lets take a look.

Sent you a PM

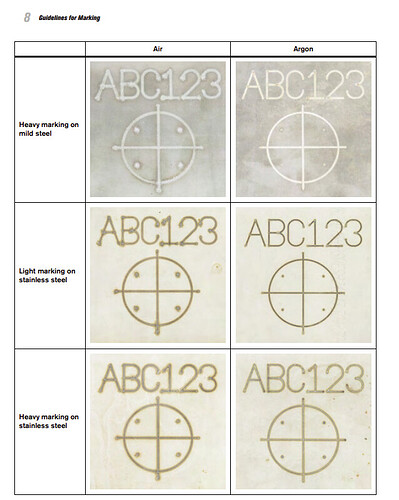

With the help of @TinWhisperer this is some marking I have done with my XL and Hypertherm 45XP with marking consumables. In the Hypertherm manual marking doesn’t gouge like what I have achieved but this is actually what I was looking to attain.