Marking consumables arrived today, gonna see how my schedule plays out, but prob mess with them this weekend

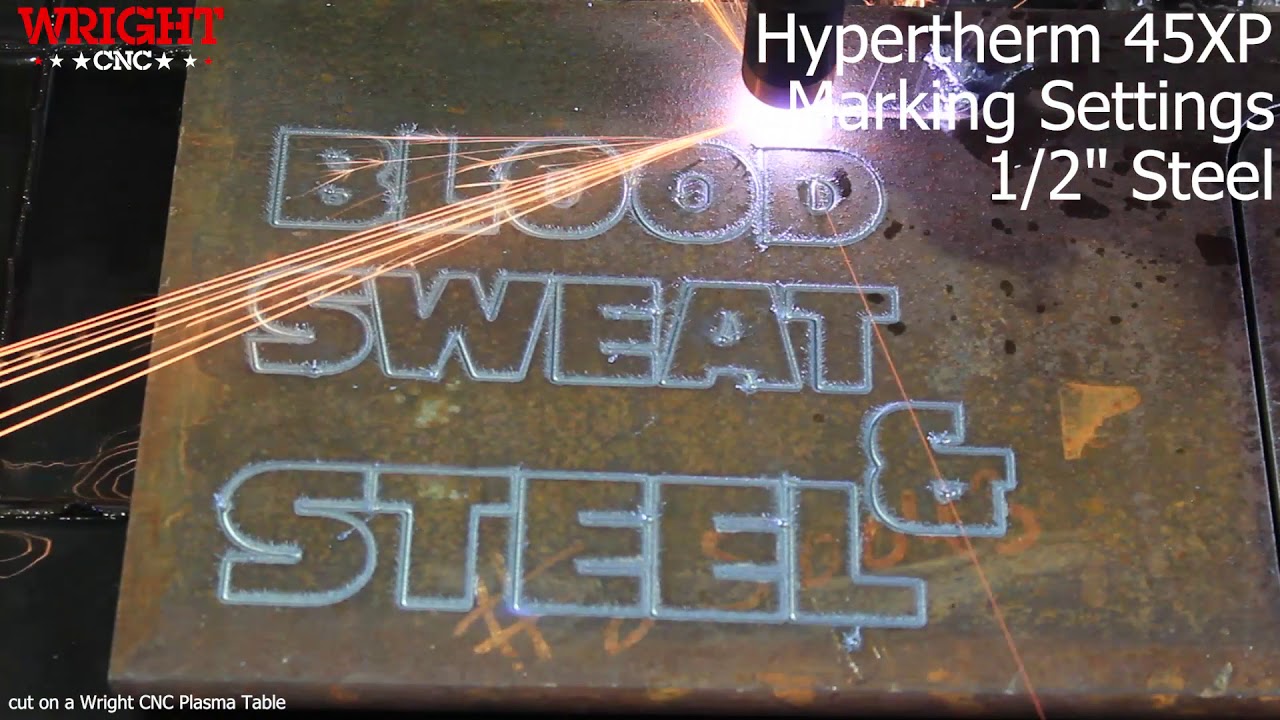

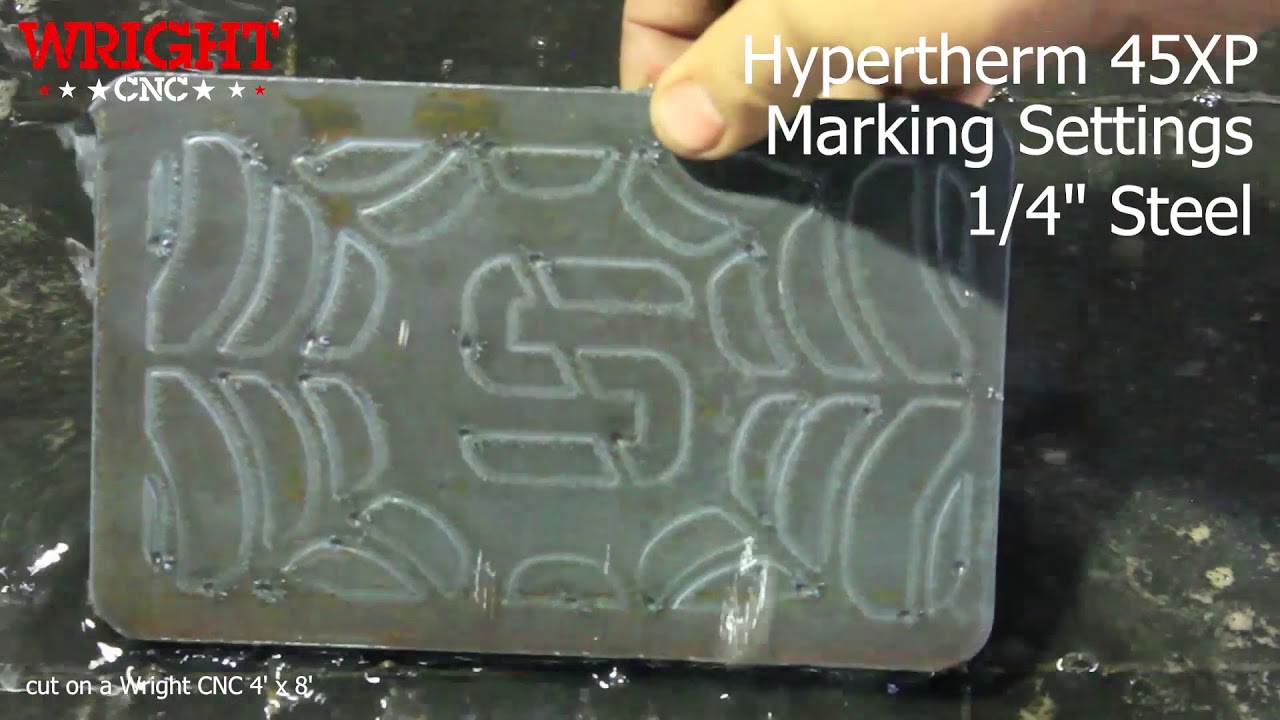

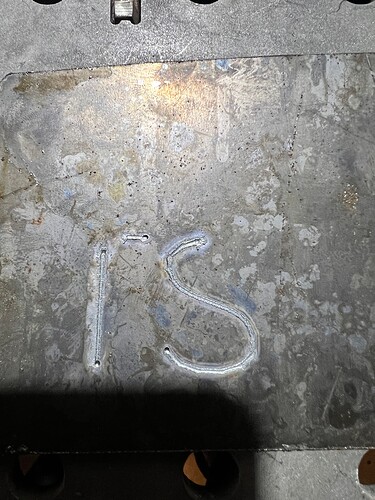

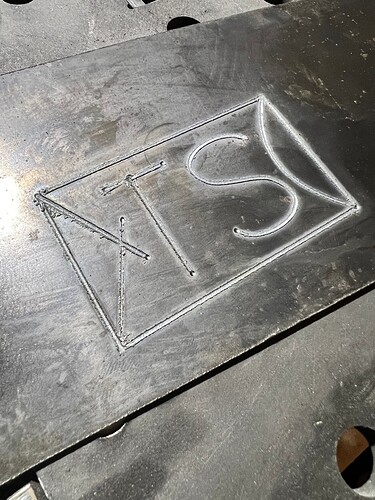

So here’s my first attempt at “Heavy Marking”:

I’m using book settings except height set slightly lower because the shield hangs just below the cutting tip.

The S is angular because I drew it really quick and wasn’t paying attention when converting text to single path.

The pics are fresh HR 16G steel, then I hit with angle grinder flap disc to kill mill scale fast, then 60 grit orbital sander.

Main issue right now is pierce delay, Hypertherm wants 0 so I ran 0 but I need to add time there.

However is there anyway to change the initial pierce? I know it’s usually longer, and it worked perfectly (the vertical line, it was a T and is the first cut). If I adjust pierce delay for other lines the first line will get cooked

Gonna make a nicer test drawing in a second

I can’t reply more so just adding onto this post:

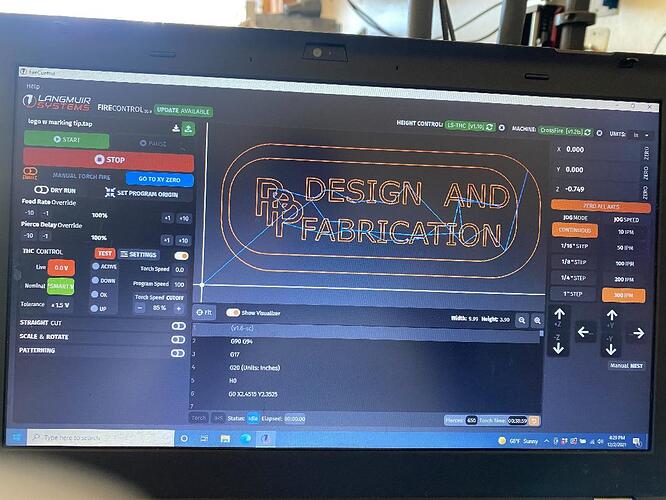

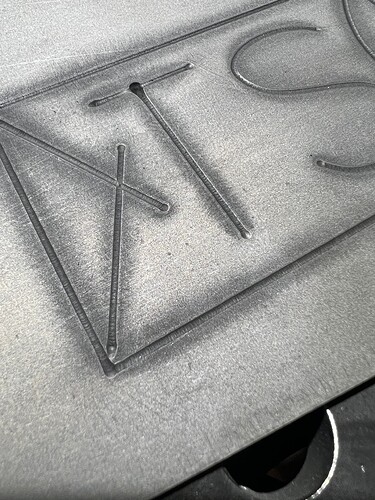

Video of second marking attempt.

.3 Pierce Delay (probably .05-.1 too slow, need to bump slightly, initial pierce makes a large divot now)

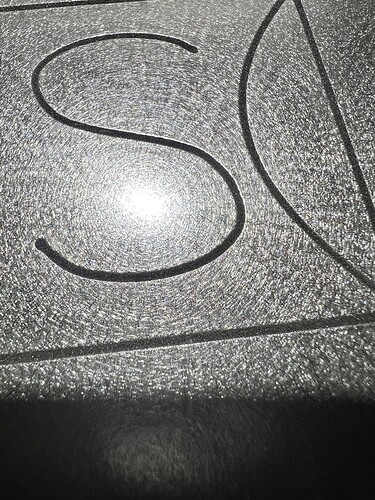

slowed to 90ipm and it looks much smoother in the gouge mark

The S is now smooth in my drawing so it cut smoother, and I put the ground directly on the piece (totally forgot last time since I’m just using a scrap piece lol)

I saw previous guy mention he ran at 111V, I just turned THC off so no voltage setting just cut height.

For cleanup I’m going to do my regular procedure, drop in vinegar tonight and take it out tomorrow then I’ll sand. I honestly think it’s gonna be pretty smooth.

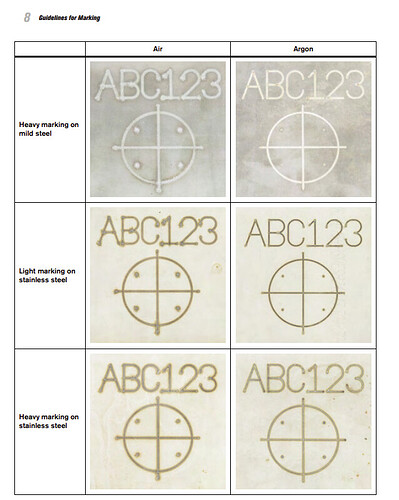

This is all with just air NOT argon yet.

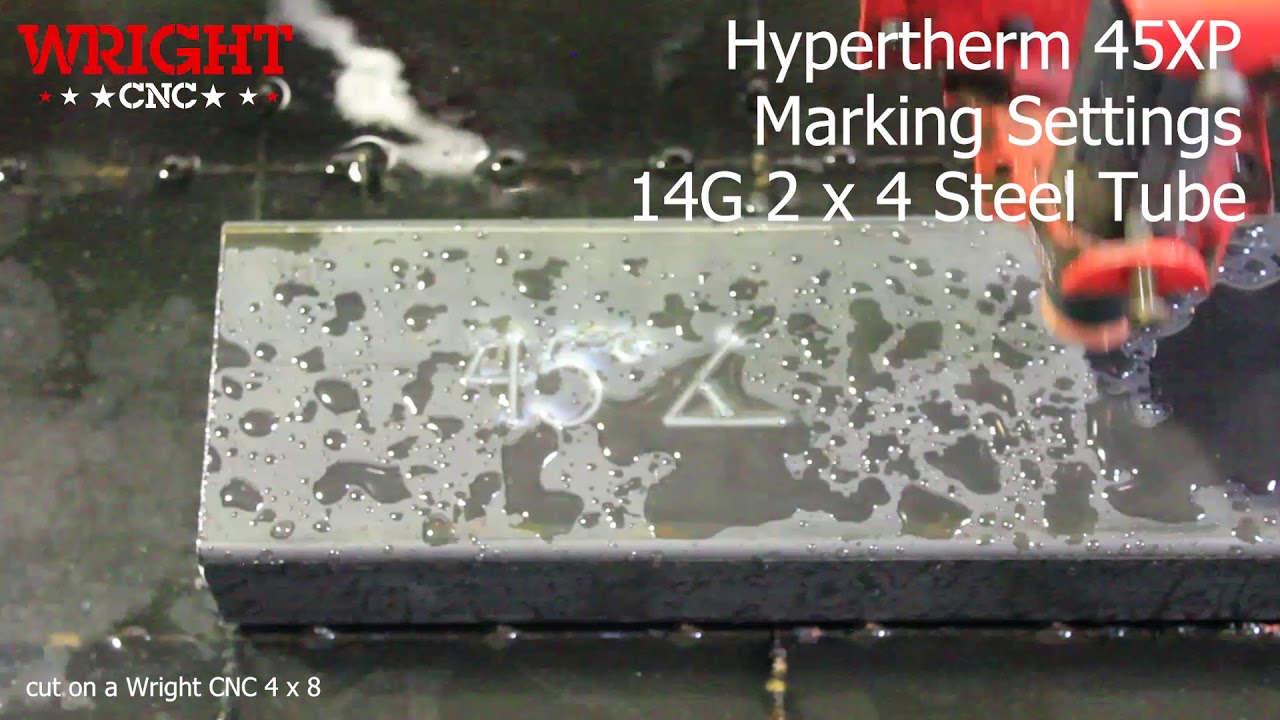

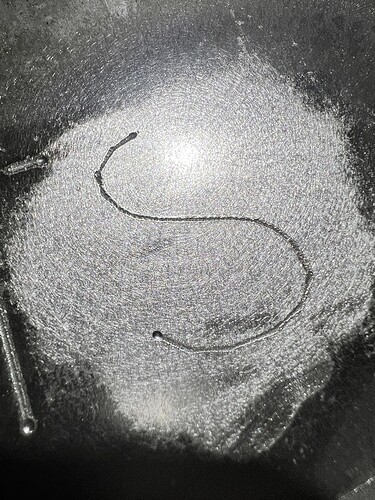

Here’s couple pics

Still can’t add a reply so here’s more

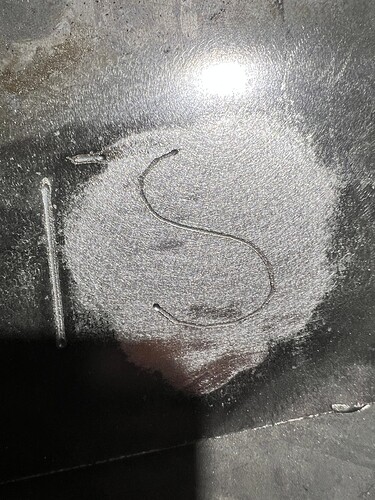

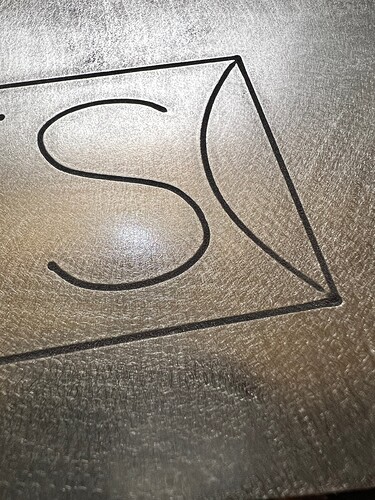

Here’s the piece right after a vinegar bath, and then after a quick sanding. Marking looks much better now although the end of cut “ball” is still there, looks like using Argon should negate that. I’ll prob mess around with Argon this week some time, got a few orders to finish first.