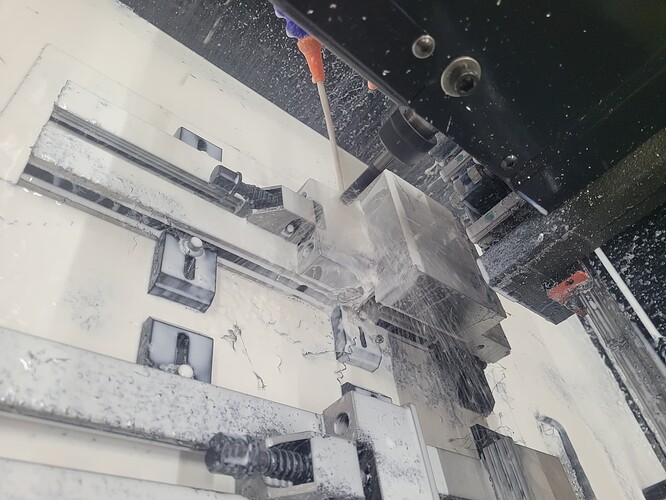

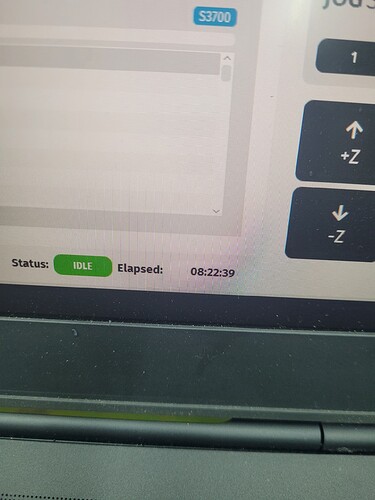

Well I posted on FB because I didnt have my computer, but again, the machine decided to destroy stock and a $40 cutter this weekend. 8.5h into the program and it was running great (13h total estimated time)

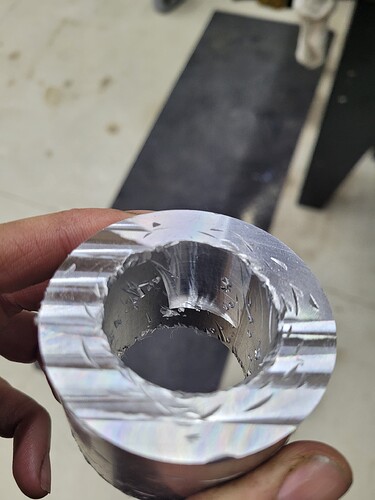

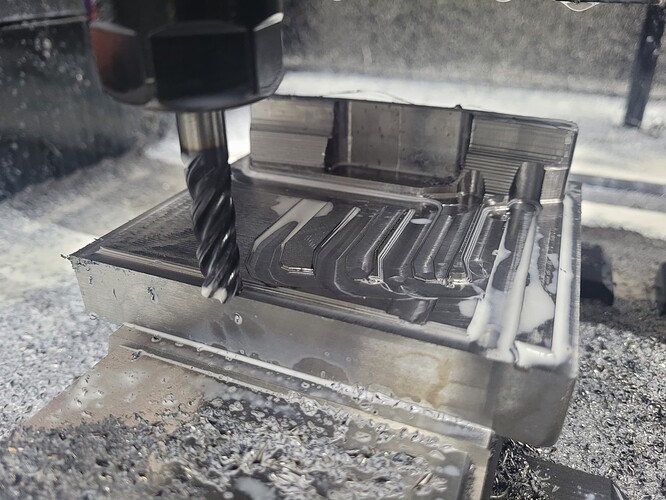

I look over to the mill and there is some serious steam coming off, which is odd. Turns out, it decided to lose its X position by about 1/2" for a couple of steps and was taking 1/4" full slotted cuts or more right into my part. I didnt catch it at first due to all the flood coolant blocking the view, but when I paused it to see why it was cooking coolant I saw my part and tool ruined. Checked the zero after I was done and it was shifted ~1.5" off to the left, so the motor is losing position some how. Same thing happened in the y direction on the last part.

At this point Im just pissed off. Its now ruined $80 in cutters, $100+ in material, and at least 20 hours of my time. I have nothing to show but some scrap metal blocks, and have no direction for a solutiuon. And at this point, and not really confident enough in the mill to actually work well enough to justify putting things in it that it wont destroy.

Ive said that Ive pushed back on people thinking this machine should be a $40k Haas, and that its just a hobby mill, but at this point, its not much more useful to me than a show piece in my garage. Maybe an aluminum only type mill.

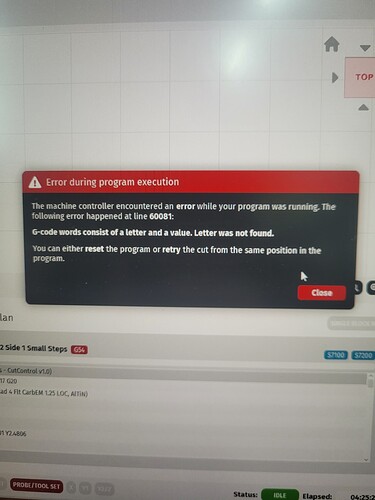

I checked my code and its fine as best I can tell. I sent an email (slightly angry at 10pm at night after 9 hours of working on a part) with my code and some pictures to see if they have any idea what to do, so we will see.

All in all, I think Im just very disappointed that using Langmuir’s recommendations, and giving it all the time to make a nice part, I just end up with wasted money and time.

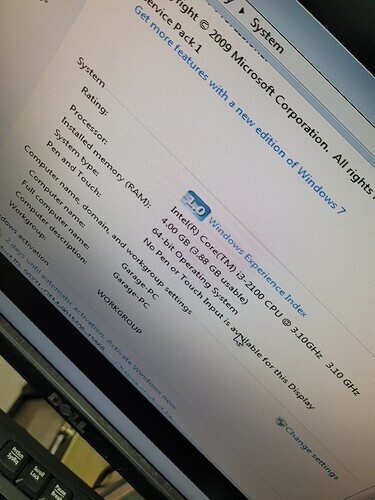

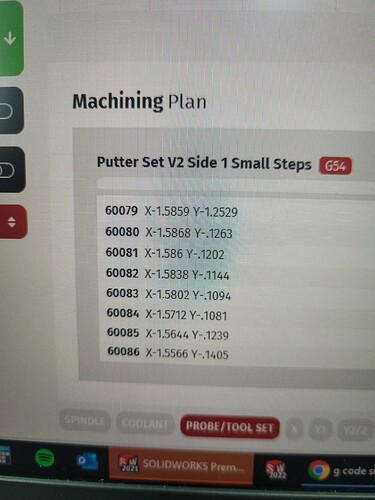

Here are the settings I used. Maybe someone can tell me where I messed up if I did. I can even post the code if anyone wants.

4140 Steel.

3/8" Carbide 4 flute cutter

3700 RPM

25 IPM

0.04" Max step over

0.08" Max depth of cut

Open to suggestions on what to do to make me not just look at selling this and trying to find a used Tormach or something. I know Ive had a few complaints (leaking seals, terrible door design, lack of canned g code in Cut control) but for the price, if it worked, this would be a killer machine.