I have a ground loop issue that i have been unable to solve, its difficult to diagnose when emails get answered every 3 days and i dont have cell or internet service in the shop for a tech call. im just kind of at my wits end trying to make this a side hustle honestly

Are you able to provide answers to the questions?

That does definitely makes it a lot harder to commutate for everyone involved. Not an ideal situation.

Are you using used to transfer your files, usb drive? do you design in the shop on your computer?

have you updated firecontrol? what version are you running?

If you are able to provide us with information then we maybe able to help?

i bring my laptop into the shop with stuff i have designed.

im going to bring the controller to where i can have internet access after seeing there are some firmware updates that im not running and hopefully that solves my issues.

im running the latest version of fire control as far as i can tell.

do you know the answer to any of these questions?

@TinWhisperer he did answer the questions…your speed reading missed it

ya i answered them in the quote. i should of changed the text color to make it noticeable, sorry.

i have the crossfire pro

hypertherm 45xp

raw voltage

smart voltage

2 ish years set up

it doesnt seem to cut well without thc

ive never had an issue with straight line cutting but i dont use it often at all

random

I didnt even see that. Never had any answer in the format before

.  i digress

i digress

Being it was in the quote block I assumed it was my quote.

@crosbike welcome…Tinwhisperer is one of the great member here…but he gets sooo excited to solve issues sometimes…

we will help you out here…

laptop…hmmmm…do you by any chance have your laptop plugged in when running the table?

Why the RAW voltage with the 45xp does it not have a CPC port?

i do not have it plugged in. i am using the plastic isolator and plastic washers on the screw heads as well. i was getting 0 ohms of resistance so i have a ground loop issue somewhere.

I did find the screw loose holding an electrical ring to the z axis and fixed that and its now showing that i have an OL but every test i run still says i am having a ground loop issue.

im halfway decent with some electrical but im definitely not an electrician by any means and electrical diagnostics is definitely not my strongsuit

its does have the cpc port but i am cheap and didnt want to spend the money on it when it seems like raw voltage will work ok. I was more annoyed that i had to spend more money on an adapter after buying the table. does the cpc port make a difference?

What kind of voltage does it read in fire control while you’re cutting?

80-140v ?

Can you do a THC test in fire control and let us know what the report says?

As long as the vim is hooked up correctly it shouldn’t make a difference. they do make the 45 XP without a CPC port and a lot of people have had success running raw voltage that way

i updated the firmware with no change with whatever is the latest

------ THC health check report 03/25/2022 ------

RESTING VOLTAGE TESTS

[11:59:54] average voltage = 2.04V

LIVE VOLTAGE TESTS

[12:00:14] average values: [8.39V] [12.20V] [20.62V]

its still saying i have a ground loop issue. so when i touch mu multimeter to the usb part of the enclosure and the other side to the rail to check ohms it is now fluctuating from OL to .300 and back and forth. i forgot to check cutting voltage but the vim is putting out roughly 2.35 vdc when firing in a straight line.

Way too low. This should be 80 to 140 volts .

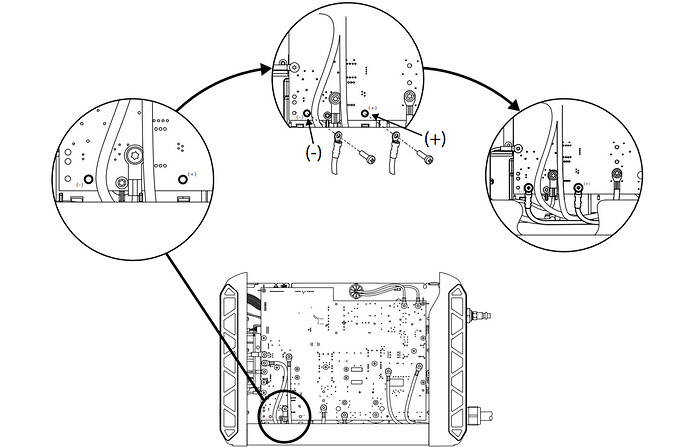

Where did you hook into your machine to get the raw voltage measurement?

And on the VIM box you have the red and black connectors going to the hypertherm on one side and PV output going to langmuir electronics enclosure on the other?

The banana clips are hooked onto the board itself. yes i have the banana clips on one side going into the vim and the PV output going into the enclosure as i recall. i will double check shortly

Let us know what you find with the wiring layout.

This is the raw voltage hookup manual from hypertherm that I posted above

looking at my pictures i took when i wired up the raw wires to my board on the plasma cutter everything looks correct. I went and test fired the torch and am getting 187v out of the banana clips and the output is hooked to the PV port and is outputting 2.3 vdc.

wiring on my cutter seems correct. I have the Red lead going into the VIM on the Red (clamp) socket and the Black goes to the torch. then the PV output going to the enclosure.

the thing is i can sometimes cut out some parts of the same file and its fine and then other parts later in the cut sequence get screwed up by the torch raising up.