As an early(ish) adopter of the MR1, I’ve been a bit of a cheerleader on the machine’s capabilities. It is a nice piece of kit, but this touch probe issue has cost me almost $1000 worth of wasted material on a job I’m now going to have to forfeit and ruin a relationship, and I’m left still chasing my tail.

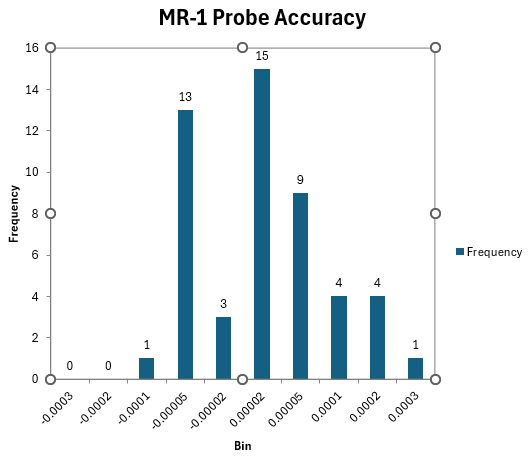

Probing off of a machined bore on an OP 2 flip part - has resulted in completely random variations in touch sensing. The probe has been opened up and closed, the three bottom flathead screwdriver nuts have been snugged, loosened, resnugged, the ball bearing plate has been cleaned and potential for any chips to get caught removed, the runout on the probe tip has been brought to within 0.0002"+/-. The collet, nut, touch sensor, and spindle shaft have been witness marked and aligned to eliminate any potential for additional runout and consistency. I’ve done everything that I possibly can think of - and have read from both the Facebook group and forums. This probe inconsistency problem continues.

Yes… I’ve turned it off and on again. Yes… I’ve rehomed. Yes… the stock is seated flat in the vice. Ive isolated the problem all the way top > down and have concluded that the issue is somewhere in the probe - and its not on the mechanical side of the probe (runout, loose bits, electronic contacts, chips under ball bearing, etc).

This may have been an issue thats been lingering for a long time - as really the vast majority of my operations have not required me to precisely probe off of a machined feature - mostly just tophat removal on Op2, etc.

The long and short of it is: I’ve resorted to using an edge finder for XY zeroing. Which has been likened to an ape using a club by my machining mentor. Its really only accurate to within 0.001", but thats worlds better and more consistent than the result I’ve been getting with the probe. Until the mini haimer shows up.

So like. Whats the deal? Perhaps its something I’ve missed… But I really… REALLY dont think so.

@langmuir

Also. Please do not use this post as a “pile on” for other users experiencing troubles with their probes. This is more of a request for Langmuir to offer formal explanation as towards whats going on with their probes, and we as a community/manufacturer can discuss expectations/resolutions regarding this matter in a respectful, helpful, logical, and insightful way.