can you do a manual fire from the trigger on the torch AND from within fircontrol?

Please follow this troubleshooting flow chart below it should identify your problem and propose a fix for it.

THC TROUBLESHOOTING FLOW CHART REV. B

I actually had that happen to me today. Found it was because I had my torch holder height set incorrectly. I’d been messing around with things

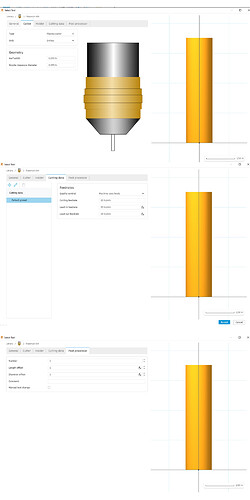

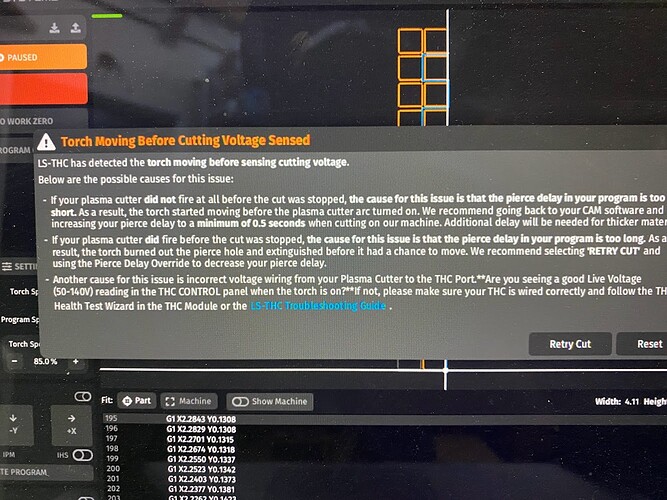

Hi, I followed the troubleshooting flow chart but nothing solved the problem, i dont know if theres a bad parameter in Fusion 360 or something wrong in FireControl:

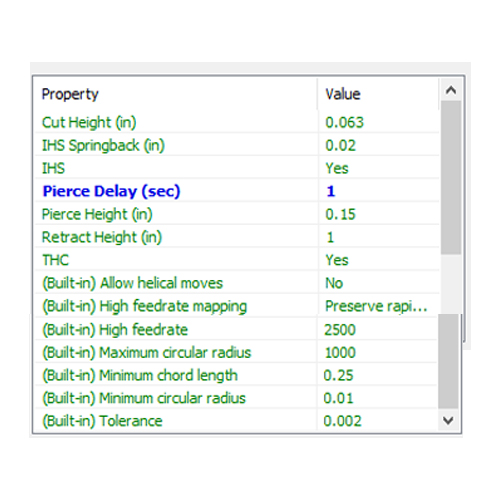

What parameters are you using in fusion?

Pierce delay

Pierce height

Cut height

IPM 20?

What material are you cutting?

Steel?

1/8?

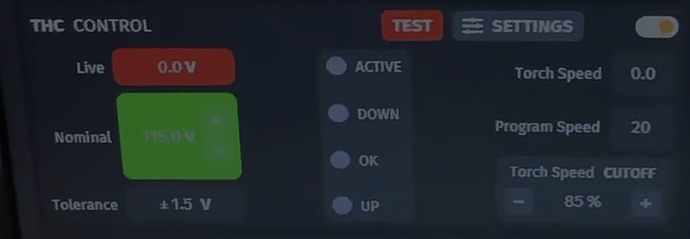

From the video it looks like you have set your nominal voltage set to 135.

How did you go about choosing this number?

Have you try smart THC by setting nominal to zero?

Does it register anything when you do set it for smart voltage?

How is your THC wired?

What plasma cutter?

Razerweld45?

Does fire control read any voltage during the THC

test?

Hi! I don’t know where can i put the parameters in Fusion 360, Someone told me in this section.

I’m cutting steel 1/4

I didn’t know about de smart voltage, i changed it but it didn’t work

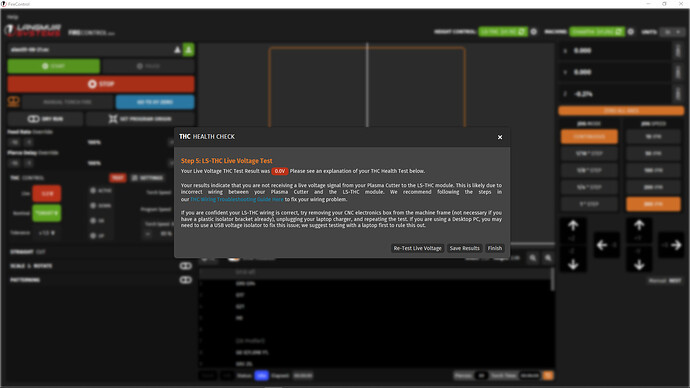

My THC is connected to Razorweld Razorcut 45 with 50:1 divisor (CNC port)

Fire Control doesn’t read any voltage during the THC test.

Hi Sergio,

The steps in the flow chart are very effective at determining why voltage is not sensed. There are many possible causes and the flowchart inspections check for all of them. Id encourage you to walk through it again. The steps require the use of a digital multimeter. The voltage checks are especially critical for diagnosing the issue.

I’m new with the crossfire and ls-thc. Everything is working perfect except I get a bevel cut with my hypertherm 45xp with machine torch. It’s beveled to the right in the direction of the cut. New consumables and table/torch are square. Cut is great but can’t get the bevel out of it in either 12 gauge or 16 gauge no matter what speed or amps. Nothing is working ! I’m ready to trash this thing! Any help would be appreciated.

Rotate your torch 90 deg. If the bevel changes 90 deg, the problem is internal to torch. Make sure not overtightened.

Post pics and video too… video of a test square cut helps sort out cause.

its getting so exciting to roll the dice on if this will work or not… i use it perfectly fine… dont change anything… turn it back on a week later and it doesnt work again… its like this thing is barely hanging on for dear life and its just getting exhausting… i havent changed anything, moved anything, nothing … and now my thc isnt working… again… wouldnt it be something if something i paid so much for would just work… wow wouldnt that be nice…

update… like usual… just unplugged/replugged everything and turned everything off and back on, on my 3rd thc test its good now… what a joke this thing is.

Now need to hurry up and cut before it decides to stop working again!

welcome to the forum…we would be glad to help…

Has the table been working fine before?..or is this your fist few cuts?

It can happen…did you read it?..did you use the THC trouble shooting guide that it links to?

In order to help we need the following information.

what type plasma are you using?

what software are you CAD/CAM in?

what metal thickness were you working on?

what were your settings…Pierce delay…cut speed…amps…

Hi,

thanks, i was messing around with the piercing feature and by increasing the delay from .06 to .09 it worked. i appreciate the effort.

Is there a common fix for when THC works fine when my laptop is unplugged? I switched to a mini PC and touchscreen and now and will not be able to unplug it. Thanks.

Check your continuity from USB to ground off your electronics enclosure. Likely there is something making continuity off the frame of the langmuir to that circuit.

I’ve been running mine with a mini PC for years with no issues. However, it is plugged into a power strip that has had the ground prong removed from the plug.

Could it be because I had grounded conduit mounted to the table frame? I have the control box off of the machine right now, and from the USB ground to the control box frame is open line. I just got my new Hypertherm 65, so cleaning everything up and going back together soon, should I be doing anything else while it’s apart? L1 inductor mod? I can’t imagine I’ll have an issue with high frequency now, but maybe its worth it since its all apart?

I had been having intermittent THC low voltage issues. I have just solved another one of mine (hopefully permanently) today. The hole in which the USB inlet sticks out of the electronics enclosure is not quite the right size. I wrapped a piece of electrical tape around the usb inlet where it exits the enclosure and my THC voltage is now showing between 110V-120V (i am using an Everlast 62i with RAW voltage hookup straight to the terminals). If you were experiencing similar issues, i would try to make sure that the usb inlet is not touching the electronics enclure opening and try your THC test again. This was what was causing my grounding issues. Hope this helps!