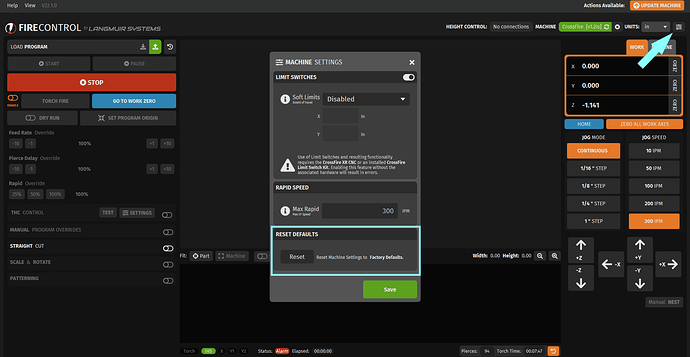

@JDE is exactly right, resetting machine settings to factory default via the Machine Settings window will resolve this issue. This process only needs to be done in FireControl v21.1.5 because previous versions lack the reset function - feel free to revert back to v21.1.4 once completed if you prefer. We’re updating the Limit Switch Kit Installation Guide to contain this info.

I missed the step of resetting the machine to defaults. This solved my issues. Thank you!

Got mine, just waiting on my new mini-pc to arrive so I can run the newer FireControl.

Now I have been having issues with FireControl freezing after it does the initial height touch on the material. Doesn’t seem to happen if I disable the limit switches

Im having the same problem with program stopping right after it moves to pierce hieght, almost like it wont reconize the M3 code to fire the torch. I am also having a problem of the software puting a soft limit on my z axis(where ever my z is located when i turn on the machine that is the highest it will let the z travel). All problems stop if i disable the limit switches. I have updated the machine firmware and I am running version 21.1.5

@barrettefab @RRyerson and anyone else with this issue:

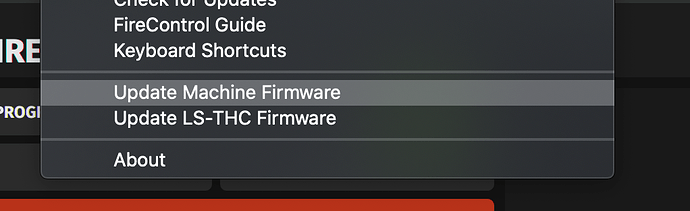

Updating the Machine Firmware from the Help Menu once more will resolve the issue with the Z-Axis Soft limits. There is no need to ‘Reset Defaults’ again if your Homing is working as expected.

Users who have yet to update the machine firmware to 1.3LS will receive this bugfix when they update as well.

Cool thanks for the info, I will give that a try.

@RRyerson I have also experienced the same issue with the z-height limit.

@langmuirsystems I’ll try the firmware update, It was just updated to 1.3LS a few days ago so it could have been just a bad flash

Yesterday I reinstalled the 1.3ls machine firmware and it seemed to fix the z axis limit issue, but I have yet to run the machine since the reinstall and will have to report after i do.

My kit is on the way… WOOOOhooo.

Question: Can I Home the machine and then type in coordinates to then set my work zero?

thanks!

@langmuirsystems

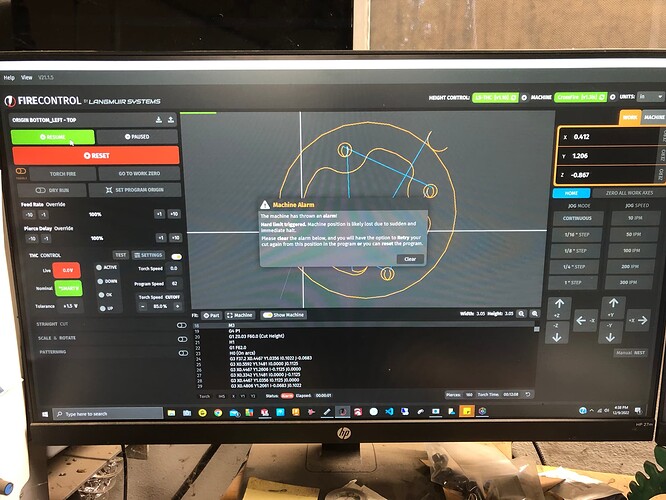

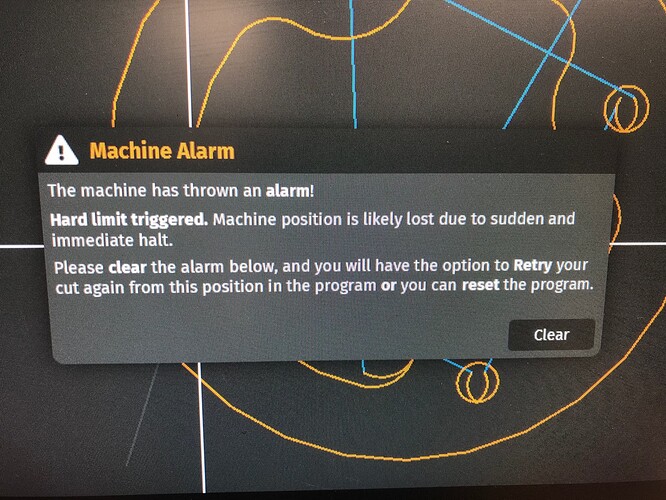

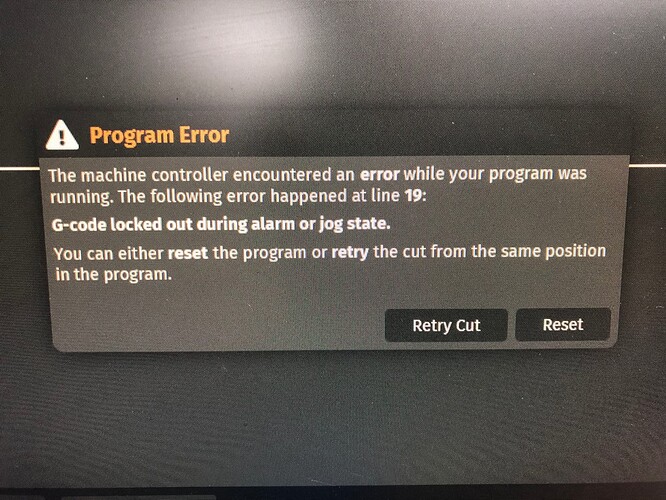

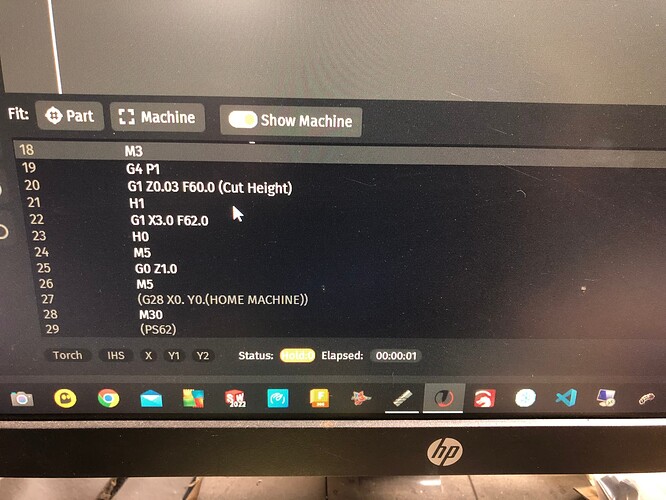

@langmuirsystems I did a test cut after reinstalling the machine firmware and it did fix the issue with the z axis limit but I’m still am running into the problem of the machine stopping on the M3 at the begining of my programs. Below have attached the error code that comes up when the machine stops

We are looking into this- It may take us until tomorrow to get back to you. Sorry for the trouble!

It seems that the machine limit origin (Y axis, based on the new limit switches) and the work origin are at different corners. After homing if I import a drawing, by default it imports to a space that is unavailable to cut. Many people (including myself) use brackets to square up sheet stock at work and (former) machine zero. But now, those people have to rely on soft limits instead of hard limits for the actual work zero. To me, it makes far more sense to have the machine and work origins in the same location.

Currently the work origin is at +33.xxx inches on the Y axis while the machine origin is at 0.000 inches, which is very confusing. Why is there an offset when there doesn’t need to be? The limit switch kit has plenty of room to mount on either side of the Y axis. Is it possible to have a setting where the user can configure which side of the Y axis the limit switch is mounted so that the origin (0,0) is the same for both machine and work axes? Or can we enter negative values for the Y axis soft limit?

This new split origin system is very confusing.

Maybe I’m missing something, but it sounds like you just need to zero all work axes after you home it.

How long is it taking most of y’all to get the kits? I ordered mine two weeks ago,and haven’tseen anything yet

I think they’ve been pretty popular ![]()

Just got my shipping confirmation the beginning of this week so they’re getting through them.

Same here I am getting same errors

We’ve been looking at and test this issue all day and are able to successfully cut and run our test Crossfire and Pro machines with limits. That said we are releasing one more minor update to the firmware in case this is causing your issues. Please update your Machine Firmware one more time to receive it (there is no new version number).

In addition, we have noticed that with some strain the blade connectors of the limits can pull out of their connectors but not from the plastic sleeve. This can cause no issues if there is enough connection to keep the circuit closed but can cause phantom limit triggers. Please make sure they look like the below.

As a potential last option, can you provide some more information about the state of the plasma cutter at the time the limit switch is being triggered. Does the same trigger occur with the plasma cutter powered off (and THC)?

Let us know how you get on with this!

@langmuirsystems I reinstalled the firmware and checked my limit switch connectors as you stated in the last message but i am still have the same problem. It seems the m3 code is working as it should(the relay is clicking in the controller) but the torch wont fire with the limit switches enabled. I did a test with the plasma powered off and the program started like normal even with the limit switches enabled. As you can see on the pictures below i did recieve a error message i didnt get yesterday. Possibly the thc or plasma affecting the limit switches?

(The code was recieved when the plasma was powered on)

I am using a prime weld cut 60 by the way

Just confirming: this limit hit (and subsequent alarm state) only occurs with the plasma on? This points to noise in the system causing these triggers. Is your Primeweld one of the newer style Cut 60s?