Finally. it was a long wait

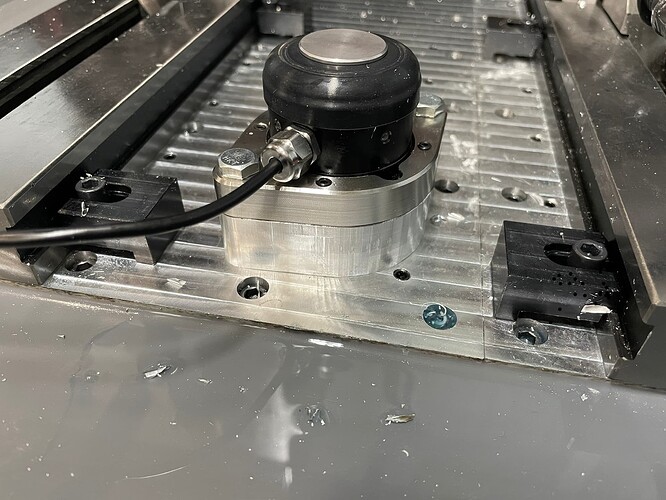

Just a simple 1” aluminum spacer for the tool setter, I attached the fusion file if anyone needs it.

MR1 Tool setter spacer.f3d (63.5 KB)

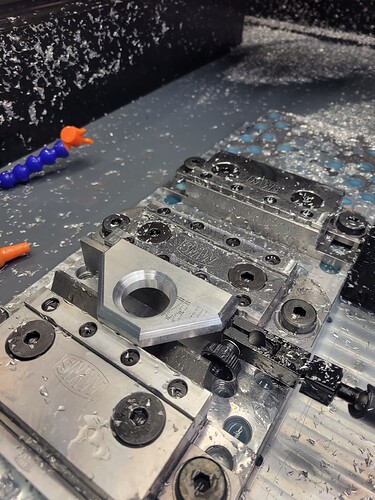

Looks fantastic! That looks like real skill went into it. Can you share what it is?

Nice looking part! Did you mill the long slot, that’s between the two bosses, from the top side - or after you flipped it over?

It is a bracket to hold a light on an ATV

you are looking at the bottom in the pictures. I milled that side first including the slot then flipped it over and milled the hat off. the hat side went ok but i need to figure a better way to hold the piece. The two bosses are hollow for a screw to go down inside to mount.

I dont know about skill…Heheeee

i just tried to open this in fusion 360 and it will not open due to it did not supporting that file

Got some brackets cut out and welded on for an Landshark anchor system. The guy wanted a lower tie point for his ropes.

Sorry, didn’t realize it saved that way. I fixed it.

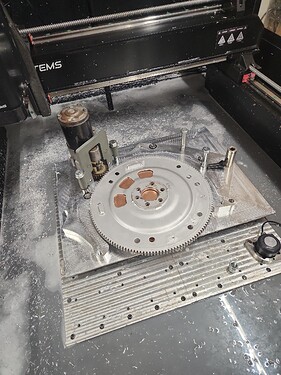

Yes. I’ve made the biggest part yet on my MR1.This is an engine adapter plate for a transmission swap in a race car. That was cut from a 20 inch by 15 in 1-in thick piece of stock Biggest Part ever made on the mr1 Next. I wanna show you what everyone needs? To hold down their large aluminum stock pieces. I made it and call it the Mega vice. I really like my machine it’s been working great and very friendly to operate I’ve had great success and look forward to making many more of our large aluminum parts. I really enjoy seeing all of the nice professional Parts everyone is making I’m very impressed

amazing work! What motor and trans does this go between?

That’s bad ass! Now I want to machine a new mod plate for my car.

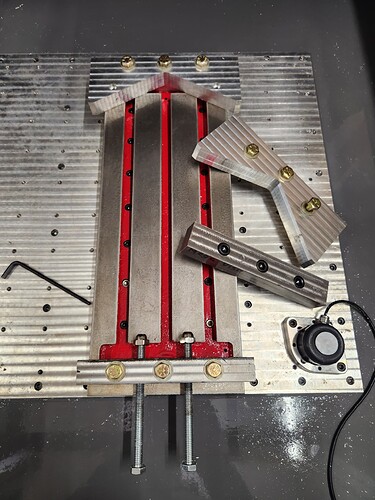

Great idea on the mega vice. ![]()

![]()

![]()

Would you mind sharing what t-slot table that started as?

Quite a Project! I’m having trouble figuring out what the red strips are. Can you help - or am I being dense?

If you are talking about his vise. Looks like the t- slots are painted red

Wanted to show and describe the big megabytes a little better.It’s built on a milling machine table with 3/8 inch T slots very useful for holding parts down. The lead screw bar on bolts and bolts to three T nuts so it can chase a smaller part toward the end of the vise the movable jaw removes and replace with the flat jaw the end jaw un bolts and turns around and becomes a flat jaw. I had to make this to make a car flywheel for example it’s not possible to bolt down a large piece of aluminum and machine the perimeter with clamps in the way everybody knows that strange there is nothing like these Jaws on the internet for holding round stock if there was it would cost thousands of dollars I’m excited I am an amateur I never had a CNC machine I’m also excited to see all the professional Parts everyone is making. And by the way my mr1 CNC milling machine is running terrific. Got to go

Thanks! I see that now. That’s what I get for looking at this on my phone screen. Very ingenious idea!

Like Daniel asked, what’s the motor conversion? Very cool work. MR1 is my first CNC machine and I am very daunted by the learning curve. Current problem is I had to move so MR1 from november is still in shipping crate… ugh…

Hi. I wanted to answer your question about the engine adapter plate.This plate is for a Honda K swap. I’m working on. The adapter plate is for a Honda K series engine to bolt up to a General Motors automatic transmission. This is for high horsepower drag racing it’s a front wheel drive 4t65e transmission. Also will work with some 4l60 rear wheel drive transmissions with the small bell housing bolt pattern.