As a veteran and VFW member, I do not find this disrespectful at all.

No disrespect intended at all. Just meant it was a nice back drop. The link you provided contradict what the military does with fallen soldiers. They cover the casket with a flag. It says not to use as a cover.

Again I understand there is a fine line with respect. I just assumed it was patriotic.

I do understand all of these view points of Tom, Bill and Phillip. Bill and Phillip are showing support and honor by displaying this symbol. Tom is following the tradition of honoring the symbol and actual object.

Don’t have an answer for you, though.

Nice damn work brother!

How the hell did you get to cut this on the mr1 is there enough space to cut this I do like it though

It is a fantastic job. Kudo to him. I bet that piece of T6 cost $300 per valve cover.

But the cool factor is worth thousands.

Everyone that looks at that engine will comment. I made those. Priceless. ![]()

I would like the cut file on that cover I have a LS in the shop and I didn’t think that the mr1 had enough cut in space to do this

I bought the MR1 with the intent that I could face off small block chevy heads if it came down to it. Best I can remember the LS is only about 24 inches long, so the valve cover would fall inside the work envelope.

Excellent work @FastFabPerformance !

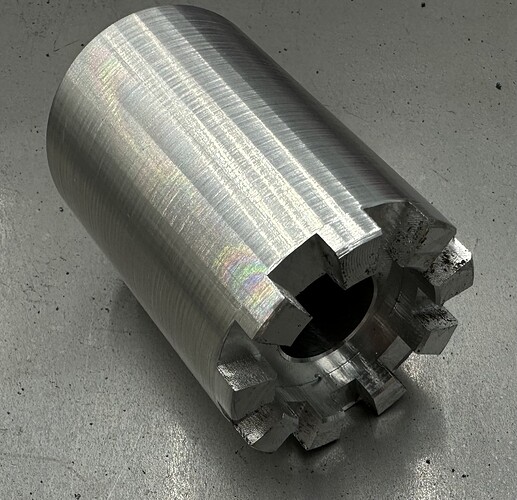

A couple parts/tools I made for myself.

1-speed handle for the vise on my vertical mill

2-drill adapter for raising and lowering the knee

Very nice job. You should be proud of those.

Thanks! I appreciate the kind words!

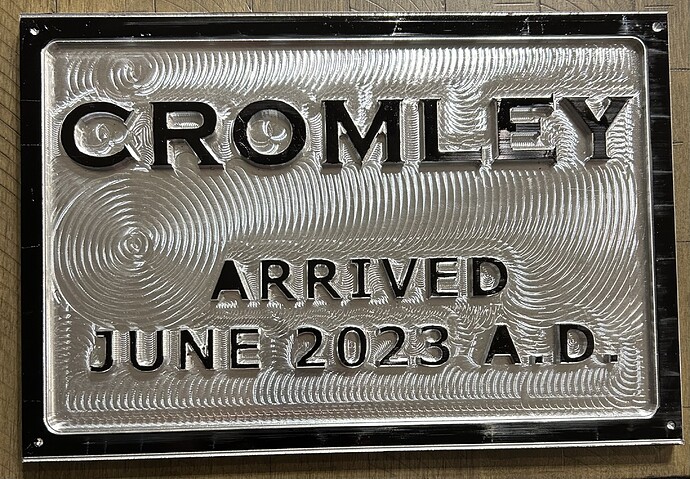

Finally made my first part today. It’s a plaque for a giant dinosaur statue in my front yard. It isn’t perfect but it’ll do the job. Fusion is most definitely my weak point. Took 6 attempts to get the file right for each tool.

Looks awesome!

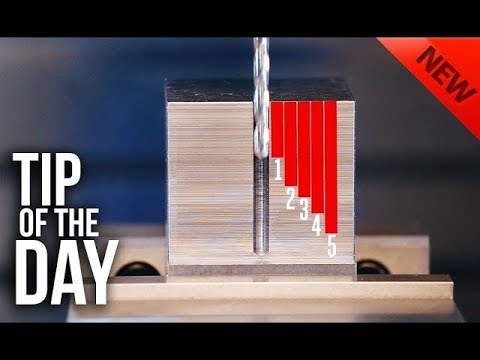

I did not understand what I was getting into when I started this endeavor as a first project (fidget spinners) but at last, we have arrived.

Excellent job. Every time I install a small end mill like that, ![]() my butt puckers up.

my butt puckers up.

Does this need to be post processed? I am new to this and I have an MR-1 ready to go. What steps do I need to take to cut this file? What size stock did you start with for this? Which tools did you use? Thank you.

All you have to do is open it in Fusion and create your tool paths. You will set stock size etc. in the manufacture space in fusion. You may want to watch some of the tutorials on this as it as the basic steps required to make anything.

In the drilling section of their Cutting Data Table, what do they mean by “accumulated pecking depth”?