We’re printing 500 products with 3 parts each, have 4 X1Cs running ABS-GF 24/7. Started about week ago and everything running smooth so far. We started with 40 spools, looks like we’re about half way through. ABS-GF is a wonderful filament, beautiful surface texture, laser markable, hi temperature, solid material.

Probably twice that before I have the money put together. Second week back to work after being on layoff since December. I have accounts to get built back up first.

I wonder if it’s a laser displacement system for bed scanning / more accurate topography / bed leveling?

I’m not sure but I’m wondering if they’re thinking of another trick up their sleeve and they’re actually going to do it scanning in the future.

That could be used in conjunction with the laser system. If you were to scattered a bunch of different keychains or badges that needed to be labeled on the build plate the scanner could run over it first and determine how to nest the logos on what is currently on the build plate.

Eliminating the need for indexing parts

![]()

I used to sell those displacement sensors (micro epsilon), and they are very accurate, but it’s another system that needs to interpret data to be accurate over time.

The way that tool changer is on the front, might leave options for a third print head in the future.

I saw on the CNC Kitchen video that there is a pen attachment also. Lots of stuff to be able to attach, options open up. Don’t want to see a router though. That would be too much.

I need to check out that air purifier also. Might get that for my galvo laser. Be nice to have help with the printing of ASA, ABS, PA…

Speaking of vids, I am disappointed and surprised to see that there are not many big name reviewers. I’d have bet money that Teaching Tech, Makers Muse, and one other whose name I can not remember would have been on the forefront. They have nothing.

Lot of people I have never seen in any other 3d print vids searches doing reviews.

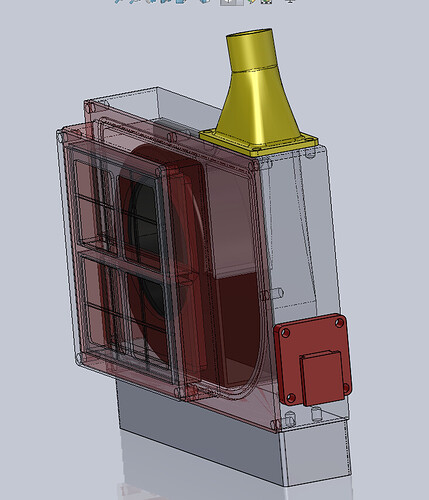

I’ve been slowly picking at designing my own 3d printable PAPR system (to adapt into a 3M bayonet). It wouldn’t be difficult to adapt to be a in-enclosure filter. It uses Roomba HEPA filters (x2) and there’s room underneith for a carbon filter too. The fan is 12v, but I wish it had some more head pressure.

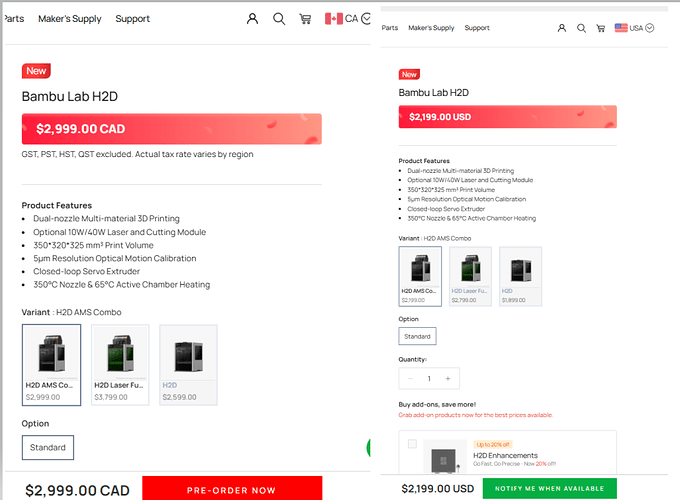

Pre-order is no longer available for the US market and when it was available yesterday, it stated that shipment would happen around April 25 and then later in the day changed to “April 30”. Canada market states it will ship April 3rd.

Yes, when I ordered it said April 25 but my receipt says April 30

Now that I’m back from a work trip, a follow up on this. Everything is printable (PLA here) and fits. Haven’t gotten it wired up for batteries, nor the bayonet adapter done yet because my single nozzle voron doesn’t like supports (yet), but everything in principle fits, and I’ve tested it with a benchtop power supply. Need to find “suspenders” or some mid-body belt/strap method of keeping it on my person.

I have another fan that I’m going to use test how much I can overdrive the voltage for some more air pressure / flow. I want to see if it will work at 18v without letting out the smoke pixies (2x milwaukee 12v in series with a buck converter necking down).

This is a very cool project. I have a 3M ad flow that I’m currently trying to make some adapters for power tool batteries. The 3M batteries are unreasonably expensive.

The entire PAPR system from 3m is ridiculously expensive (seriously, $1500 for a battery powered fan?). Hence why I’m trying to make my own with “off the shelf” parts. If you’ve ever spent much time sucking air through one of the 3m respirators, you know the strain it puts on your diaphragm.

Great video Craig.

It sounds like I need to learn more on the “pressure advance” settings. He showed a TPU bellows print that failed with Bambu settings. He set calibrated the pressure advance settings manually and got perfect results.

Some engineers are detail meticulous, optimization obsessive, etc. There’s another term for this but it doesn’t matter. They figure it out and we benefit.

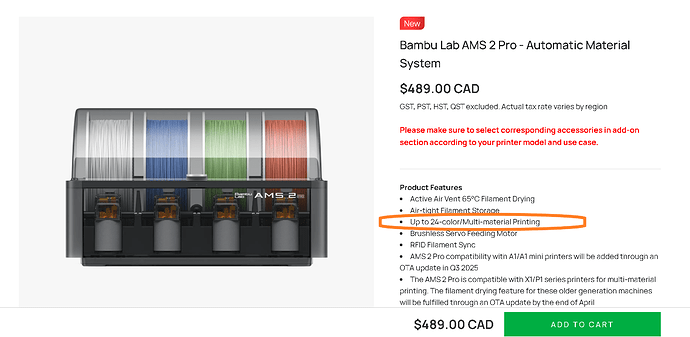

So with the new AMS 2 pro it can support up to 24 colors where are the AMS can support 16.

Do you think there’s a chance there might be some backwards compatibility where the X1C will end up with the ability to add two more AMS’s in the future?

has anyone seen the AMS hub that supports the 24 color printing?

"H2D Support:

The H2D supports a maximum of 4 AMS 2 Pro and 8 AMS HT connected simultaneously, a total of 12 units with 24 slots. "

I would love to see how this is orchestrated. So we have four feeds from the four ams 2 pro and eight feeds from the ams hd2s connecting to a hub with 12 holes? Or maybe hubs in series? And this is how 24 colors is achieved.

I’m not sure why they don’t just set it up so you can use an infinite amount of ams’s with hubs in series connected to the bambu print.

Maybe a intelligent AMS hub that will allow you to hook up any combination of ams s to bambu’s products.

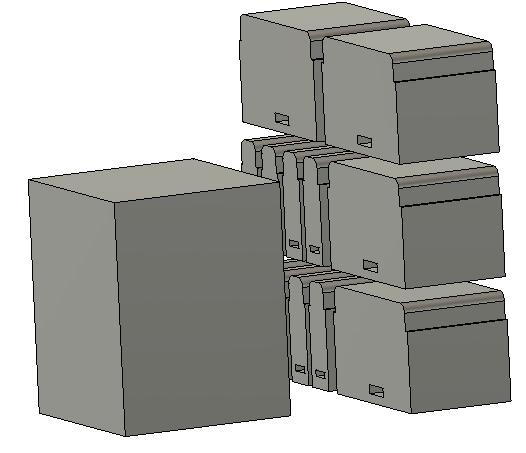

Me too! You would almost need all of that hooked up in the back with access from the backside.

The lower units would need to be on slide out shelves with lots of slack on the tubing.

This might be better. The units would be able to remain where they are and the lids lifted to change filament.

Whichever one of you guys guess one of those new bamboo lab printers first… Please do be sure and post how glorious it is, and that it just works.

It might be fall before I may be able to get one.

I’m out. Not getting one.