I just looked your machine and read about it. That thing is light years ahead of mine. Dang I’d really like to get one but it’s hard to justify when I have two already.

The laser I have is an Orion 50 Watt Laser. I upgraded it to a 90 Watt. It’s been a lot of fun. I’ve made a lot of jigsaw puzzles, coasters for local restaurants, Christmas ornaments. In fact today I just blew it on a machete I cut on the Crossfire. I made a maple handle for it and tried to put a little design on it and blew the alignment. You don’t get a mulligan ugh.

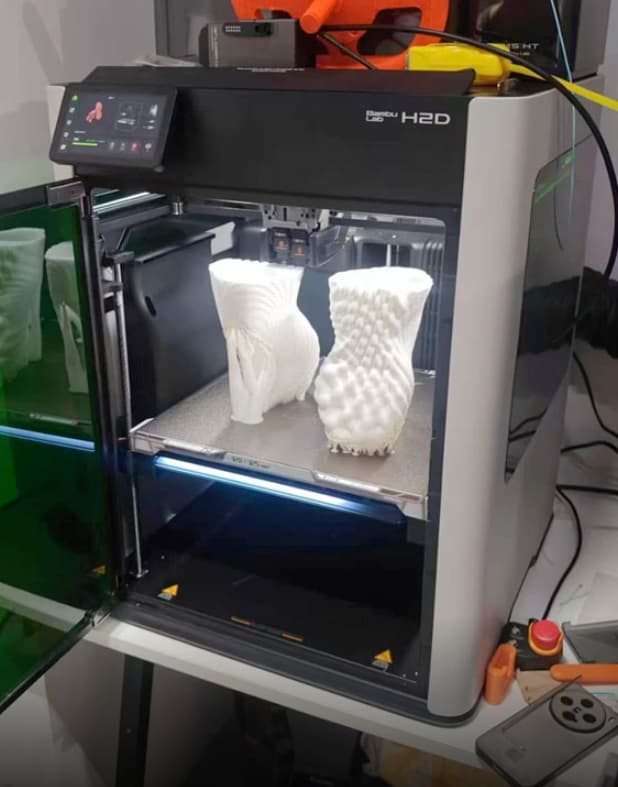

Bambu is getting ready to announce sometime about a new printer. Speculation is that it will have two print heads and the size will be larger than their current largest models.

But some say the price might be $5-6K.

All speculations at this point and sounds like there might be some patent infringements that need to be ironed out.

Yes, that is a beautiful chess set.

Thanks, too bad I’m not into chess (too slow) but it makes a nice show piece.

Yeah I’m drooling over that printer, but that’s getting a little steep for just hobby stuff. Although they come in handy. When I was setting up my dust collection system I made a bunch of reducers and adapters.

The problem you’ll have is matching the existing. I downloaded those chess pieces from Thingiverse.com

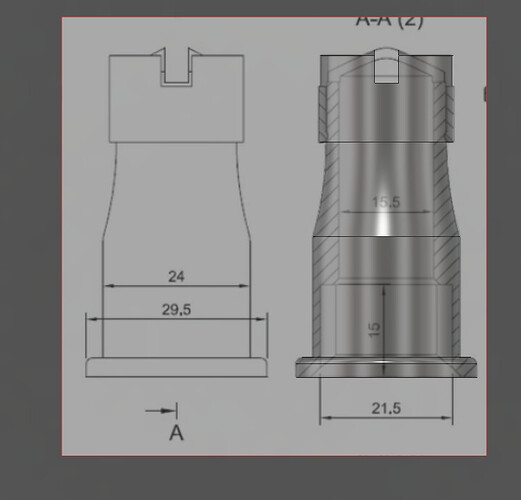

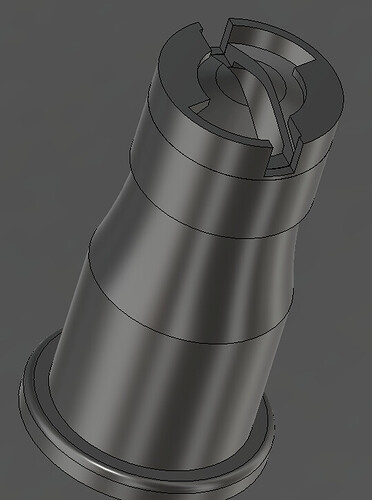

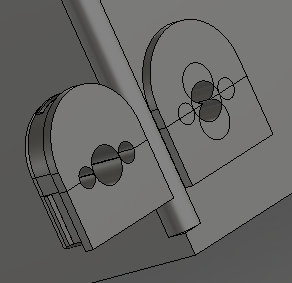

Im attempting to make 3d printed nozzles for my powder coating gun. New ones are about 30 bucks and they break pretty easily. Since I have a 3d printer, figured id try and save myself a few bucks. I’m running into issues though. I’m using Fusion360, the trial version. Ive been able to recreate the base of it, but when I try to make the top portion of the nozzle, it moves it to the base. Ive tried every option in the push/pull menu. I can’t figure it out. (Im still learning Fusion360). I’ve included pictures of the nozzle I need to design and the base I already printed. Any helpful hints?

This is a situation where you should utilize the “Revolve” function in the create menu rather than using the “Extrude” function or the "Push/Pull function.

If you included your f3d file and some photos of the actual tip someone could show you how they would approach it. @BoboBumster gave an excellent suggestion.

You make the profile. Pick the profile and the axis and there is your item.

I would caution you that it will be extremely difficult to get a machined smooth bore in that tip. At least from my experience trying to make this y splitter so that the filament did not have extra drag. (Six failures). Some people are successful. Maybe I don’t have my printer dialed in but if there is extra turbulence caused with the powder coating gun with the printed tip, it could introduce problems with your end results.

first pic is the nozzle

Awesome! Thank you! Already designing it now.

I did not realize that tip is mostly hollow space. Here is a listing where someone is selling the model for $5. Not sure if it will work for you but here is my mock up of it. You might whittle away at it.

https://cults3d.com/en/3d-model/tool/nasadka-na-raspylitel-poroshkovoy-kraski

Powder Coat Tip v4.f3d (482.0 KB)

Very nice, thank you!

Has anyone tried these new filaments recently released from bambu?

I’m interested in the PC FR one for electrical enclosures.

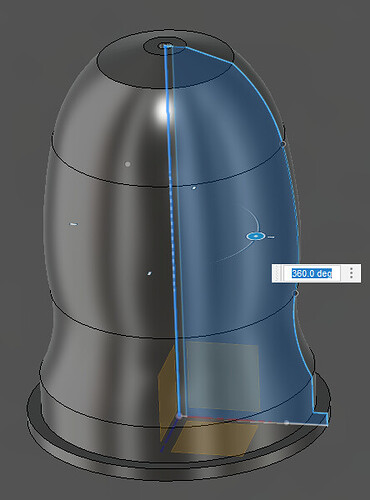

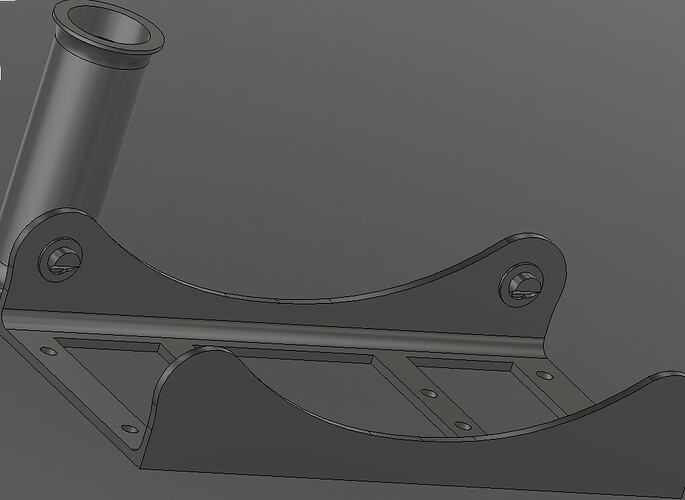

Not yet. I almost ordered some of the TPU 85A but you almost need to establish a shelf with a filament roller stand at the level of the top rim of the printer. I actually am in the process of designing such a roller for a shelf. Still printing prototypes for the roller/bearing housing:

You have probably already read their guidance in Wiki that you feed the filament straight into the tool head without any PTFE tube.

If you are thinking about the grommets for wires, I have done that quite a few times with the TPU 95A. I use 2 walls with 10 % infill. Not sure how they will hold up long term but so far I am very satisfied. I designed these grommets so I could put an entire electrical plug into the box.

The PC FR would be the cats meow for the enclosure, I would think. I have been using PETG but not planning for installing at someone else’s home.

Looks great Craig, I like it.

Sorry, not mine. Posting for ideas.

Speaking of which, if you’ve ever considered using PCBWayfor any kind of fabrication. This video shows a lot of different combinations of materials that they offer.

Are we getting closer to finding out about the new Bambu printer?

These are my favorite spool holders. They press fit into roller blade / skateboard bearings