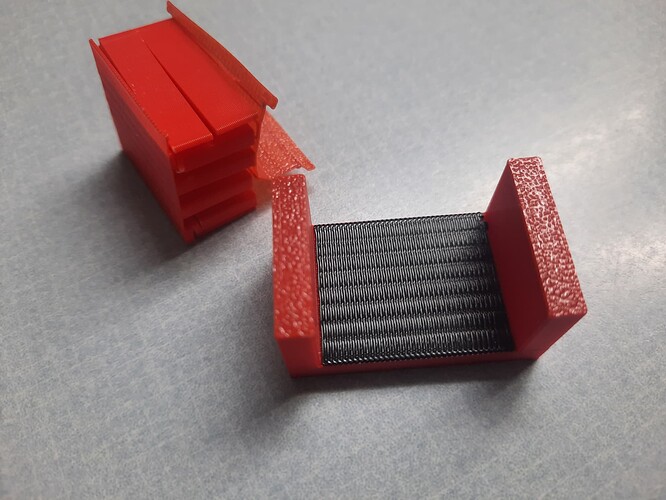

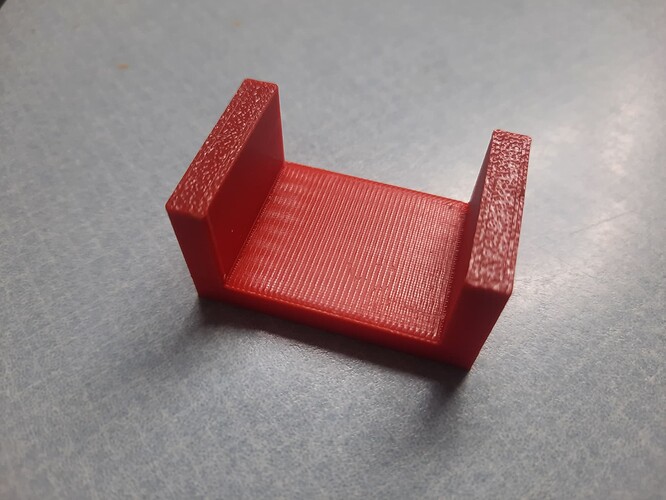

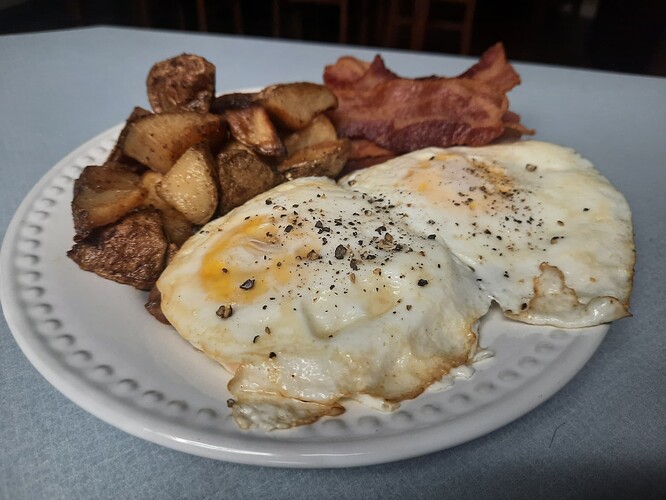

Just whipped out a test print while making breakfast, worked great.

I really like the last picture!

yes delicious, I hide some beans under those eggs. It was a tasty breakfast.

hmmm I thought that was printed

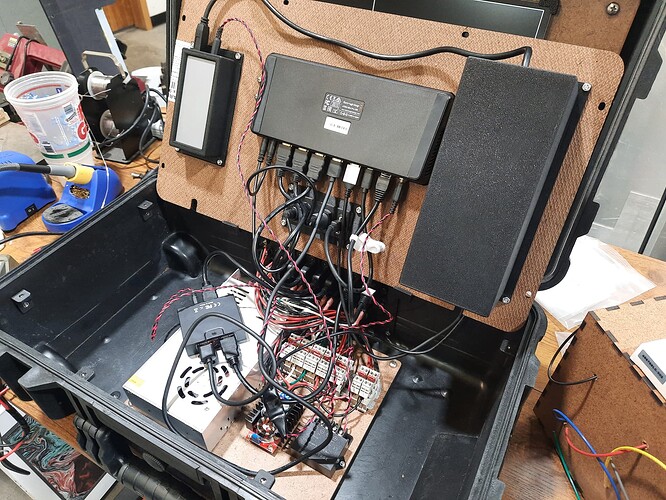

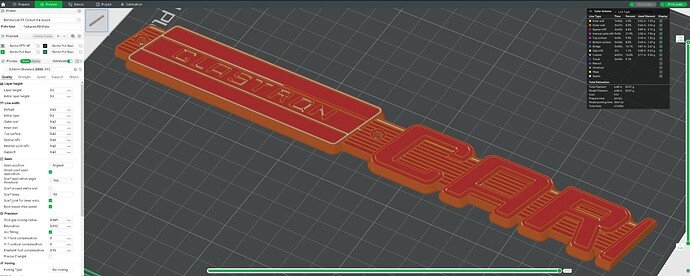

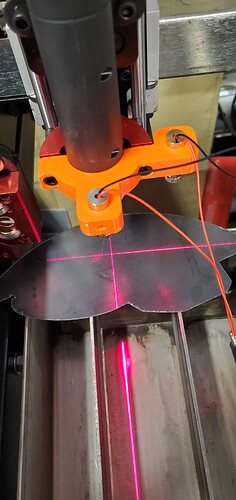

Printed a laser mount for my crossfire table. I still need to come up with a power source and wire things up. But I did a test run, looks like it will work.

An open source shaper essentially

Quite a bit involved but a very cool device.

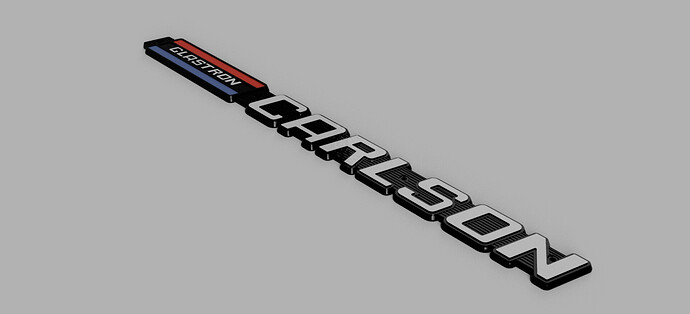

That is totally crazy. I was looking for some examples of what a finished product looked like. Perhaps missed a link.

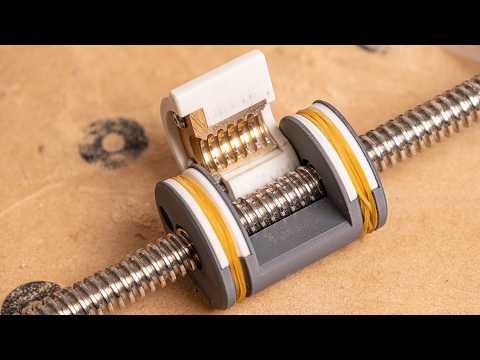

This video contains very cool high speed and close upcamera footage of the working bits in a 3D printer.

Tin: That was interesting. What I got out of it is “Don’t use grid infill. Most default profiles use grid infill.” I will have to look for that.

That looks like a lot of work. I know it is environmentally sensitive but on a home model, I don’t think I would be happy with the results. They did not use it to make pieces that needed great adhesion and strength. As someone pointed out earlier, getting the strength desired from a plastic part is challenging enough without adding in the likely impurities of a home processing unit.

Thanks for showing this Knick.

That is really cool Craig.

I noticed that Fusion 360, when paying for the subscription, you get several options opened up for more models than just the McMaster-Carr Component.

And:

I would have stopped early on with that process…so many issues!!!

So Craig, I like that video but that is not the whole story is it? ![]()

…Sooooo…Whatcha makin? None of this locking mechanism is simply ‘curiosity.’ You are making something with a locking knob or cap.

Yes???

Something with 4 axis. Hopefully something with your laser thingy.

Something the TSA won’t let you take as a carry-on.

agree, too many wires.

![Step-by-Step Twist-Snap Design Tutorial [Q&A 5]](https://img.youtube.com/vi/75uswjVayrs/maxresdefault.jpg)