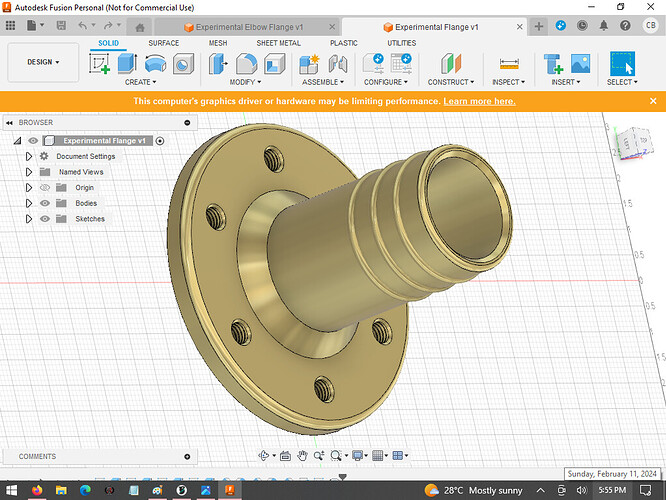

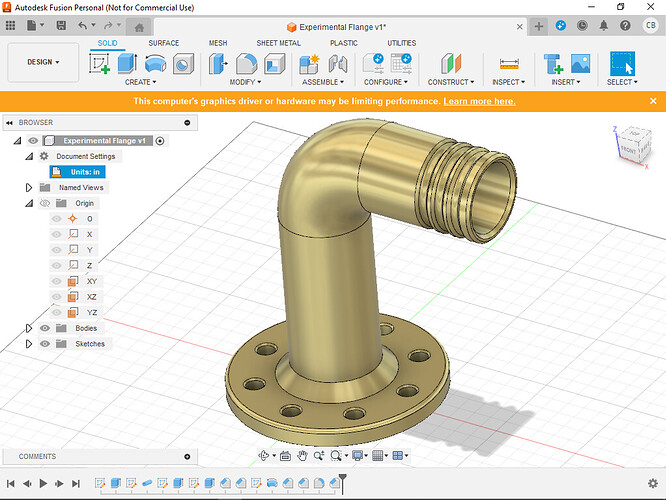

Some really good progress learning conFUSION 360. At 7:00am today I knew absolutely nothing, eleven hours later, I would say “I’m impressed”:

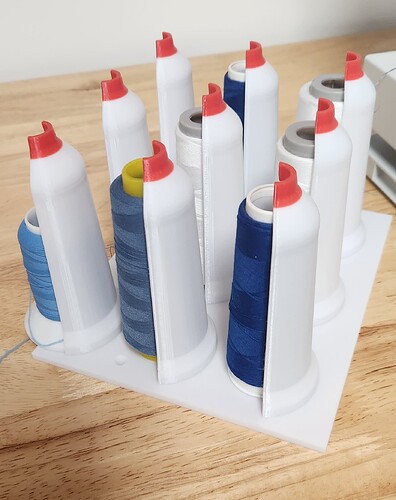

Well, I didn’t mean to do this but…I designed this thread rack from the ground up. I didn’t know if there was enough filament on a partial spool and I did want to use it up. The only spool in my AMS that was also PETG was red so I told Bambu that it was “white” otherwise it would not automatically switch.

This was printing thru the night and wouldn’t you know that about 4 am, it ran out of the real white filament and switched to the “counterfeit white” for the “tip” of the spool holder. So now I can really call it a rack because it has nipples. ![]() You can’t make this stuff up…well, maybe you can.

You can’t make this stuff up…well, maybe you can.

P.S. I am going thru a lot of filament: 4 full rolls plus partial uses of eight other spools. Don’t tell the boss.

I know…it is a really amazing program when you start to learn some of the things it can do.

Im impressed also, nice job! Looks like a seasoned vet drew that!

Any update on your 3d printing project?

Yes I will take some pics and post later and tell how they worked

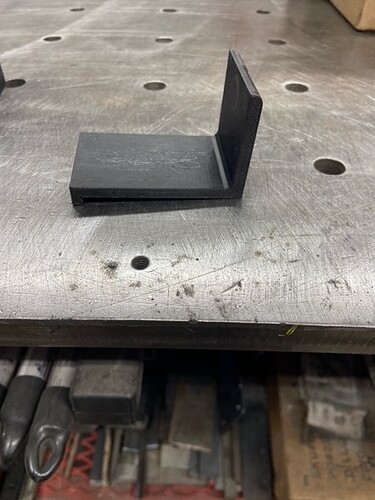

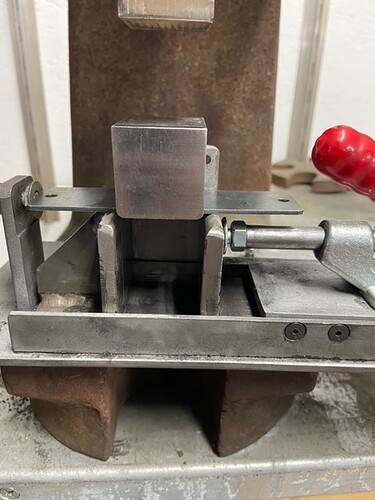

Ok here are the 3 d printed dies after maybe 6 pieces.

Here are some other views

This one flexed about 3/16" when the part started into the die. Might be able to make it thicker and help eliminate some of that but not sure its worth messing with as they seem to wear pretty fast.

Part of the reason for the fast wear was the die was not sitting perfectly square to the part, so it was loading the die unevenly.

Here is a view of the press with Steel dies and the part before and after.

I’ll do that on prototypes, using up whatever remnants, then printing the remainder in black or white.

This project used 1.5kg of filament. Made for a happy girl.

Very nice! That is a bunch of filament. But… You can’t put a price on a child’s happiness.

The thread rack is in the inside of a cupboard so it will serve its purpose very well.

You old romantic you!

I kept revising the thread racks. My wife really likes them and now feels the 3D printer was a great idea. I initially printed two “thread spool organizers” from printables.com

But they proved to be for small thread spools and would not contain the spools on a swinging door.

I got to work in Fusion and designed 4 other racks from the ground up. I attempted to modify the mesh file but everything came out wrong and it proved much faster and more efficient of design to make my own.

LargeSpoolsLessControl v2.step (1.4 MB)

SpoolRack18 v2.step (459.7 KB)

SpoolRack23 v5.step (501.6 KB)

Behold the power of CAD/CAM and 3d Printing. Soon you will apply this to repair or replacement parts.

Metal 3d printing is really cool but still few years out for normal folks. I seen articles about NASA taking one into space.

Make, Cut , Send is doing metal 3d printing also. Makers Muse did a video on a 3d printed metal gear for one of his projects not long ago.

3d printed houses (walls - all) are a thing too. Whole neighborhoods being done. Interesting interior walls, I would have to still find a way to cover them.

3d printed metal parts are becoming pretty common in custom bicycle frame building. It allows parts to be made that could never be done with traditional machining.

The engineering company I work for had a sister company a little over 10 years ago that 3d printed building components and cladding and drop in ceiling panels ect. It didn’t take off like they thought it would so they shut it down. Must have been a little to early to market or they didn’t market it well enough. I remember there was allot of buzz about it when they first started it up.

A couple of years back I had an intern who did his masters thesis on 3d printed concrete. We made the hopper and extruder in my parents garage. He had never touched a welder before. I had him do some of the welding on the hopper. I should have had him do more.

The “extruder” design I came up with as well. It was just an auger.

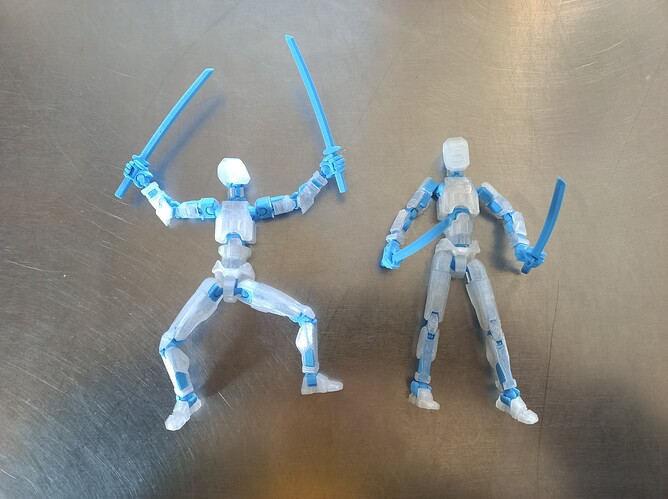

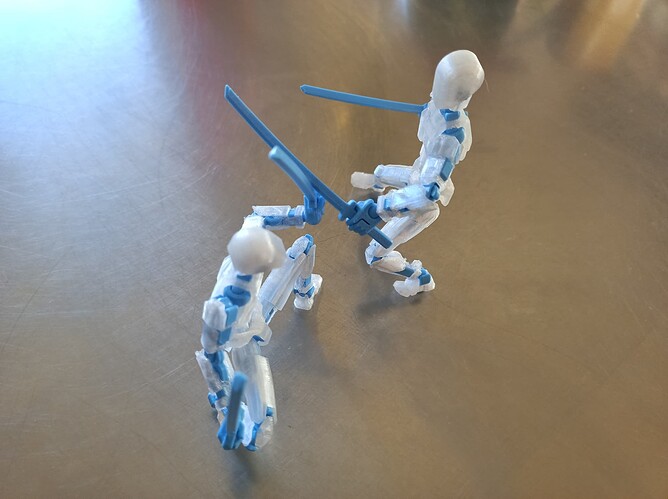

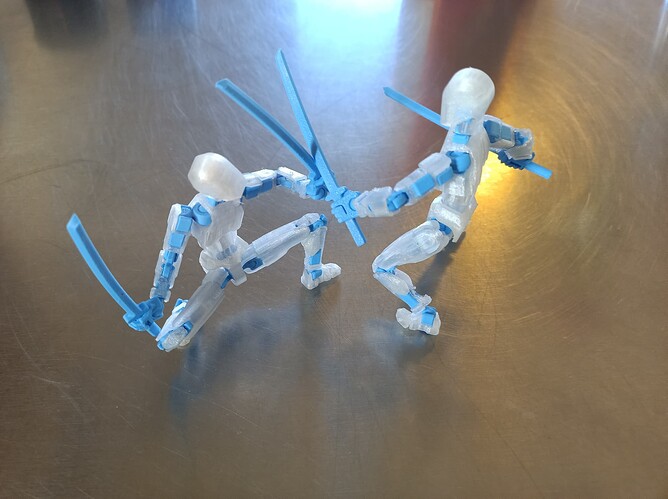

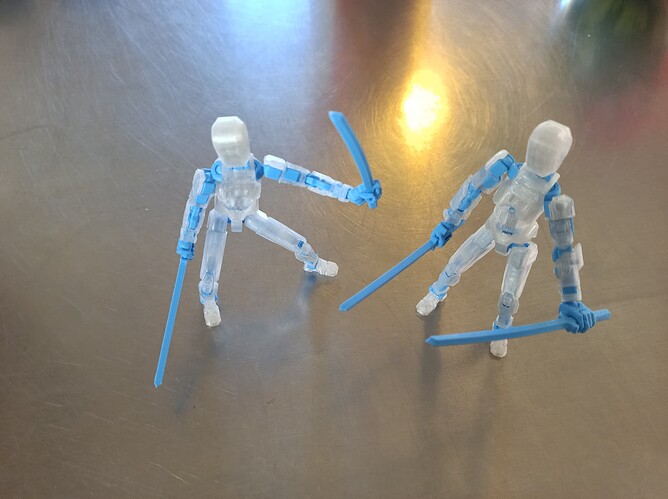

I printed these “dummy 13” s out of blue ABS and clear PETG. My daughter found them on maker world and they came out way better than I expected. all the articulating pieces work great.

I highly recommend you try this print.

I had a couple issues with the parts for the arm armor detaching from the build plate. So I ended up having to reprint three pieces.

This video assembly guide was very helpful

I downloaded that this morning. Was definitely planning to make for my grandson (6 y.o.). I will plan to follow through now.

Just got back from watching him play flag football. Last week he never touched the ball. This week he got to play offense for 8 downs and carried it once! He is the smallest on his team.

Hero!! Good move.