Not sure on design yet. Nothing is started at this point. Main concern is mixing different material for wheels. I’m not sure if the TPU will shows up in time for this weekend.

That is another good example of 3D printing and what filament to use.

PLA would likely have been too brittle, where as PETG has lots of flexibility.

Ok I like the clip but I like your clean floor better! IS that weird? ![]()

![]()

@Sticks thank you for the concern. Everything is all good here in British Columbia. I’m just choosing to step back for a while. Likely do a post in a week or two of the projects I’ve been up to. I’ve still been reading everything on the Forum. I have a good feeling about 2024 , I’m hoping it’ll be great for everyone.

@TinWhisperer…Are you working on your print farm?

So happy to hear from you Tin! To rule out you being a bot: “How likely is it that I will go ‘off-topic’ in my next five posts on this forum”??? ![]()

![]()

Back to the topic:

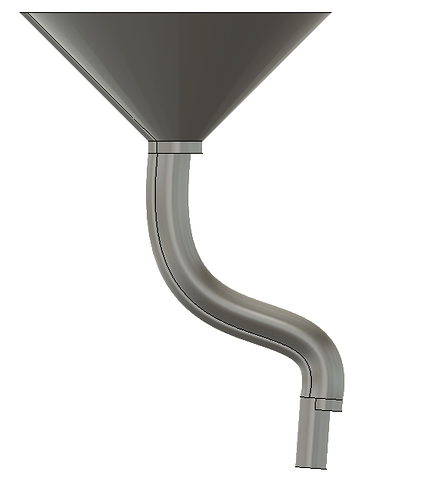

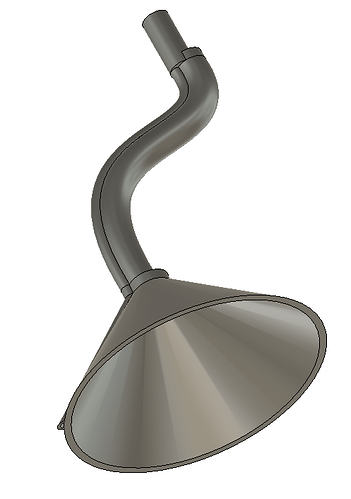

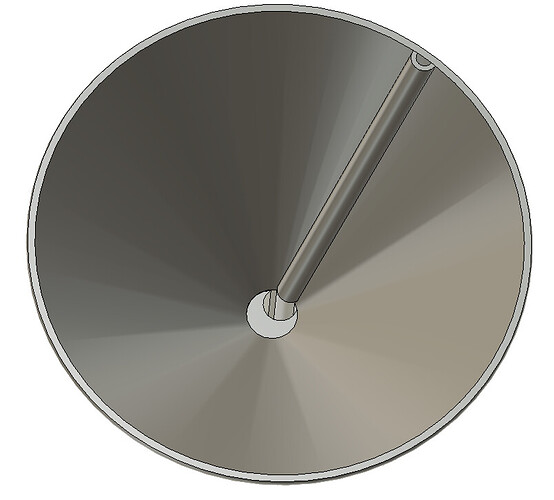

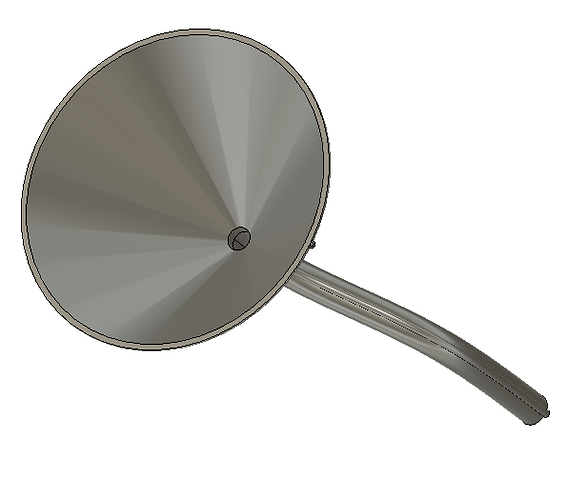

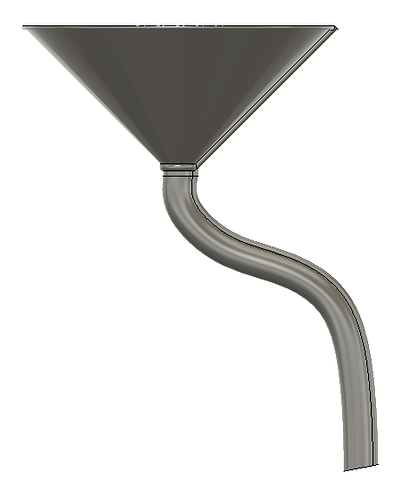

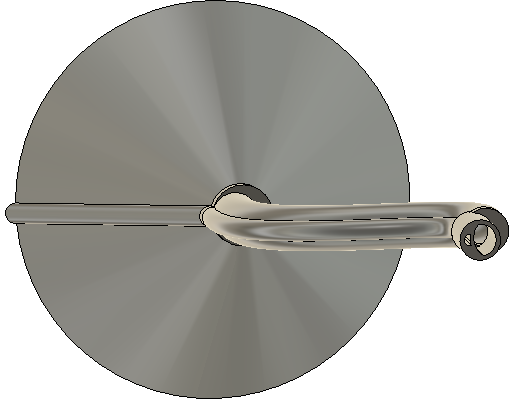

I designed a funnel last night for my printer-to-come. I am always annoyed when adding oil to the small engines how there is a long way away from the fill hole and no funnel will reach. I designed an air release passage for an air gap. I put it on the outside so that there was less restriction of the flow of oil.

I am sure there are twenty better ways to do this design but we will see how it prints. I know it will need lots of support structure.

I am open to any/all suggestions for printing and design flaws. I know it sounds poor planning but I am thinking if I want the best surface on the inside of the funnel, it needs that surface to be [UP pointing] when printing. This will cause the need for lots of support structure. Is my reasoning flawed? Probably use ABS or PETG.

I would share the dxf file but I don’t think it will translate well unless you were using Fusion 360, so here is the f3d file:

Funnel AirTrackOutside v3.f3d (305.4 KB)

Edit: Here is another funnel with the air track on the inside: much simpler to do. This one, I made the walls thinner but added the bulge at the top and bottom of the funnel for added strength.

Funnel InsideAirTrack v3.f3d (115.6 KB)

Revision of the first one (now that I can anticipate what the program is doing). Time to produced that first one: about 5 hours. Time to produce this one: about 20 minutes.

Funnel AirTrackOUTSIDE v2.f3d (261.2 KB)

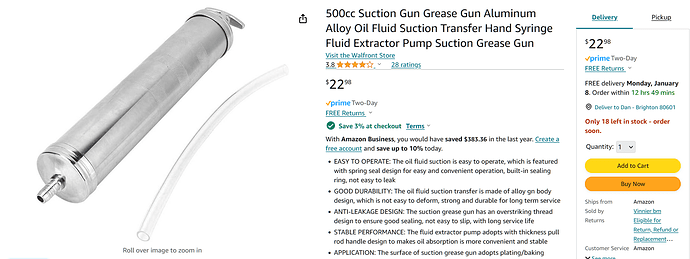

I always use a mechanics turkey baster to fill.

Like this one, but not this one.

Draining is a bigger PITA for me.

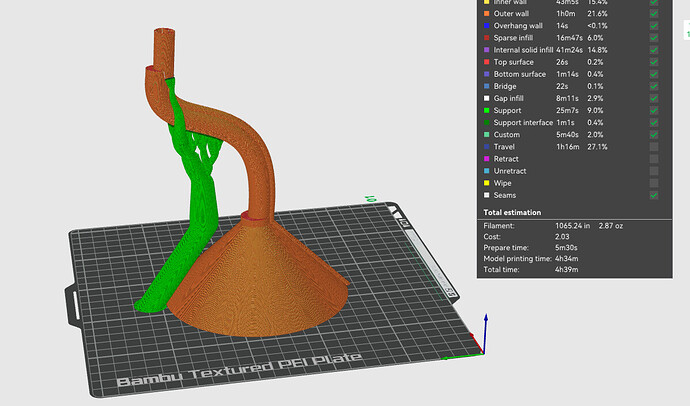

HOWEVER - please share your results. I have never tried a 2 piece round tube. Let alone a second port for venting. Bambu Lab printers do real good with overhangs so you should be able to get away with no supports in the vent line.

Might even be able to do the whole thing as a single piece with no supports if the diameter is small enough. Think thicker extrusion (.7mm or so) and maybe 2.1mm wall thickness. Less likely to sag with more wall counts and will help support itself.

No kidding! What is with that design or lack thereof?

Thanks for the suggestions. I am a few weeks away from trying.

Nice work…it does add 25mins for support tree but could try it without. Your off to a great start!

Chemical-resistant materials: A beginner’s guide - UltiMaker

Printed a couple racks for the cheapy HF nut drivers. Uses a rubberize studded magnet for attachment. Printed with matte black and white PLA, 20% infill.

HF Pittsburgh Nut Driver Rack.f3d (1.6 MB)

Don, always trying to show off. One week he has 1 printer few weeks later he has 150 and still finds time to help me!

![]()

That was a joking picture from internet to Tin because he’s taking time away. It’s great New Year’s resolution.

I always try to find time to help others.

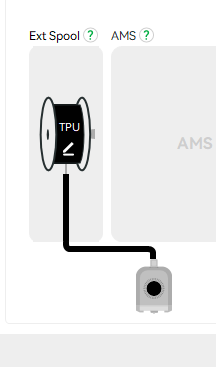

Played with TPU on A1 and quickly found out it needed to be used on the external spool and not through the AMS. I purchased regular TPU but they do make a high speed TPU that might work in AMS. Just trying to save anyone starting up some time. It’s very cool stuff compared to PLA and PETG.

Yup. I’ve made gaskets, sealing washers, replacement feet for a couch (the pads anyways). I don’t do many toy type things, but the ones I have seen are pretty neat.

I knew that. Lol

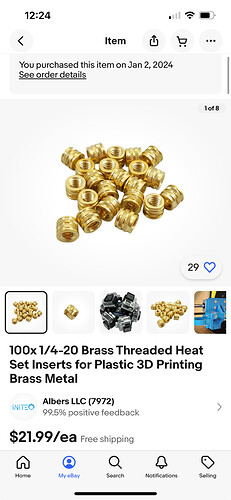

These worked great! I made test block for the 1/4"x20 inserts. I did order the correct soldering iron tips this morning. Thanks for suggesting.

You beat me to it! I’ve got some imperial ones I ordered, but they’re too long. I’m still waiting for the metric ones I’ve ordered in different lengths. Seems the imperial ones are harder to find (at least on amazon). Glad they worked so well, I’m excited to try mine.