I must be blind…I’m still trying to decypher what it says…and he hasn’t showed us yet

Pridham Studios:

https://www.pridhamstudio.ca/

Literally my exact thoughts.

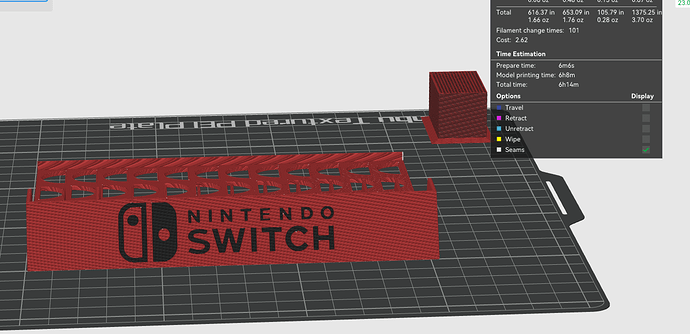

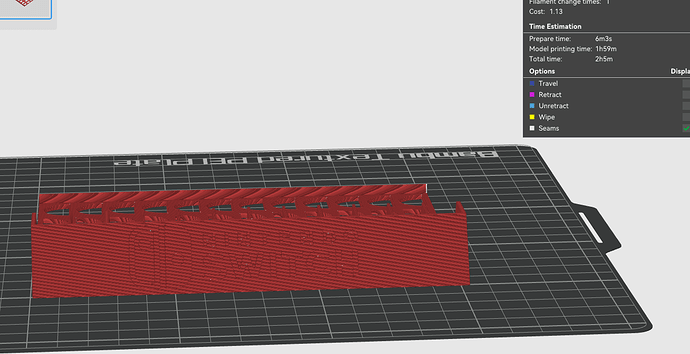

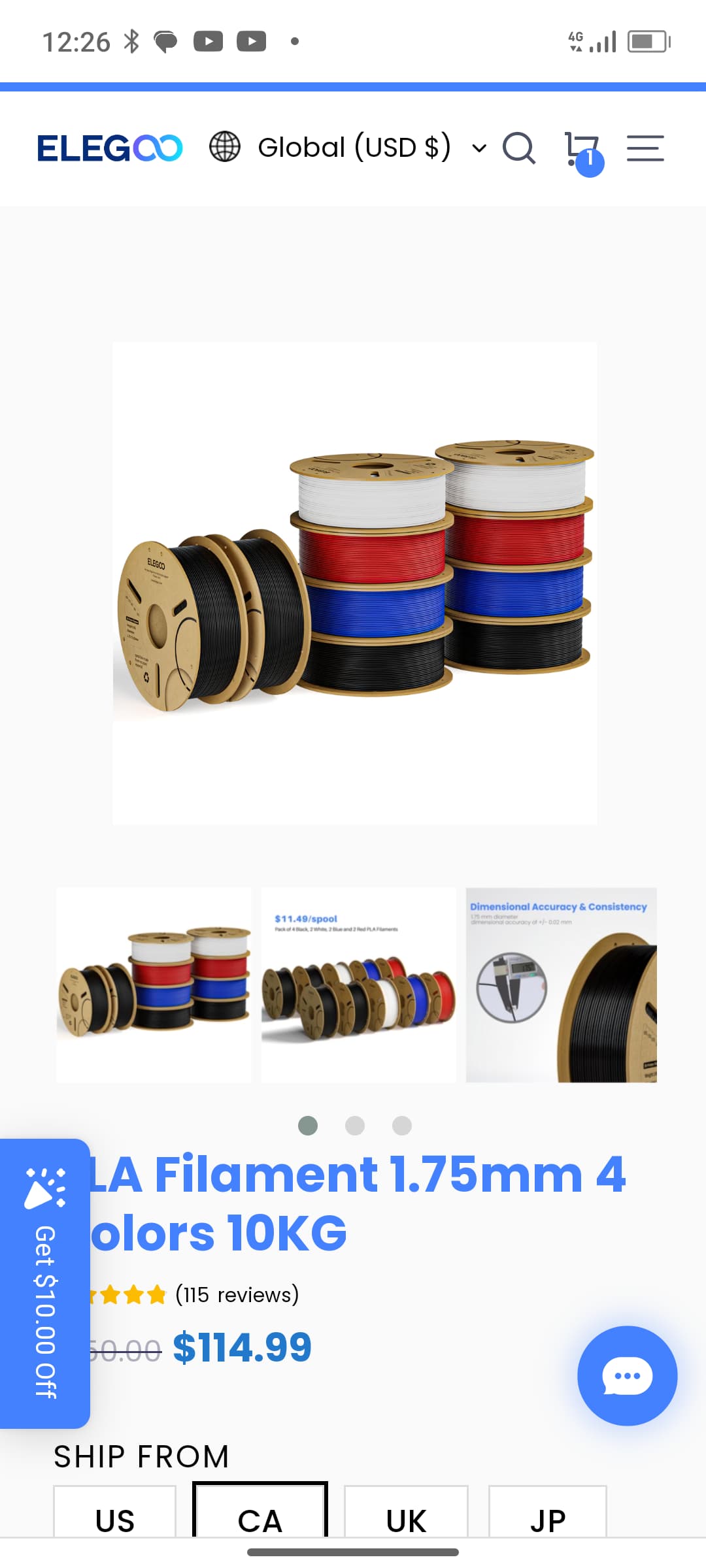

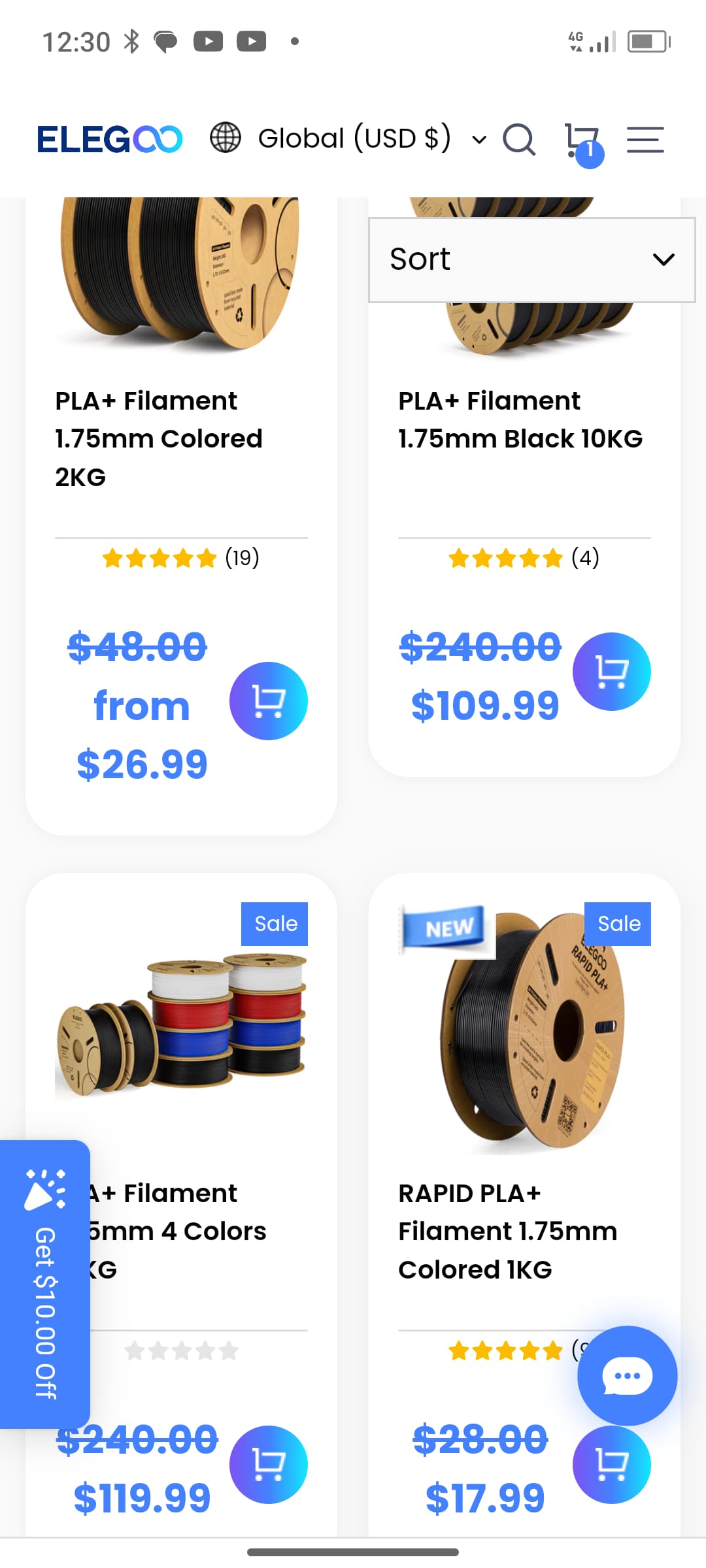

Major time difference for single color to two color print. It would have been close to 9hrs to add blue. It’ll be nice when they come out with multi head units.

6hrs - 2 colors

2hr - no color

it is crazy how much of a difference it makes

I hope Bambu does. I did pre order the prusa XL in 2021 but their roll out took 2 years and I gave up.

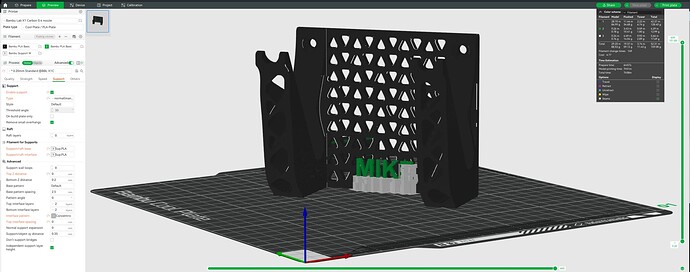

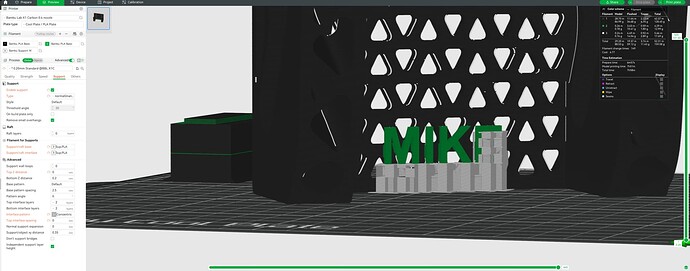

I did need to add support on my coloured letters on a similar project I did above. I tried without but it was printing in thin air . enable support and the time will increase another 30%

WOW! I sure hope it persists when I am ready.

Just asked the boss if I should order some. Her response “You have not made any effort to do what you are suppose to do. You haven’t cleaned up the space.”

I thought this was Christmas time: time of giving and forgiving. Guess she is not as on-board with the “Christmas spirit” as I am. ![]()

All you have to do is ask for her keys!!![]()

My wife has just boxed up a 5 pound block of coal to send to you…you are getting me further away from that printer. Not closer. STOP HELPING! ![]()

Uh best gift ever!!! You scored when you found that lady! Take that woman out to dinner tell her it’s from me.![]()

I heat my house with coal. Do you have any idea what that sells for? ![]()

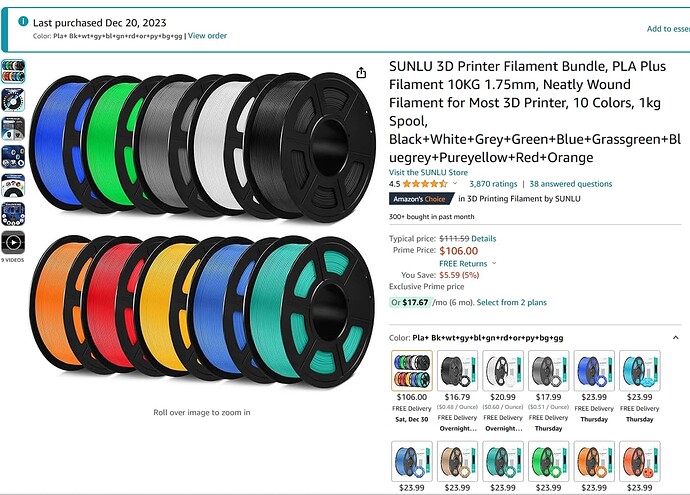

Got that filament in yesterday. That green and orange is darn near neon. The other turquoise is more grass green, and the lighter blue is kind of a dull blue, not light.

I have been using Sunlu, Esun, Polymaker, and Duramic (not a fast printing filament…needs more setting tweaking) exclusively.

One of the main things that I do is forcing compartments to my needs.

This is my work lunch cooler that keep my fresh food, snacks cell phone separate. Been lugging this cooler around in my service truck for 4 years. Printed with ASA

This is the small pack I picked up for my high voltage working. Fluke 3000FC kit with 3 amp meters (one in transit), the main DMM, 2 voltage meters (AC and DC), and my test leads. Keeps them easy to get to, protected and enough little pockets on the pack for my other tools (screwdrivers, wire strippers and whatnot). Printed with PLA +

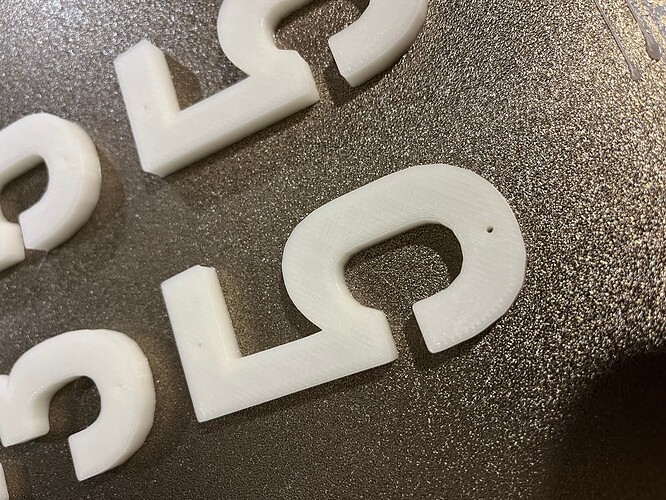

I have lots of friends ask me to do mailbox art for them, so I wanted to test out the green glow filament. I downloaded my 3" numbers from Fileshare and made them 1/4" thick. These are going outside on a post to see how they hold up in Michigan winter conditions.

Anyone have an idea how these will hold up outside?

3" numbers for mailbox or house | FireShare | Langmuir Systems

That is really a perfect application for that filament…if it works. The reason I say that is because the color is not special when not glowing, which works out better to see in the daylight. And, at night or after a blast of headlights, it gives more visibility in the dark.

You never have to worry about the bevel or cut height with that printer, do you? I am going to have to get busy and get one!

Cut height - Work area on new A1 full size is the exact same as P1S and X1C. 10x10x10”

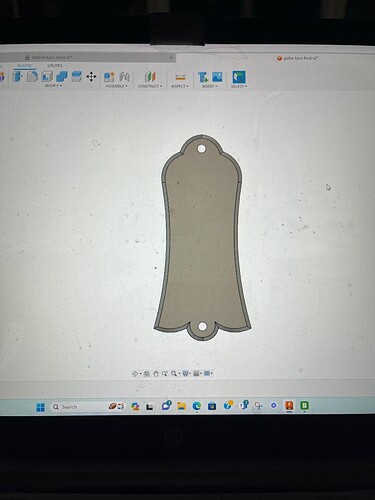

Bevel - not really sure what you mean about worrying about bevel. If your asking can you bevel edges than yes. That’s all part of the design. No easy way to do it in the slicer. I did bevel on these guitar truss covers.

I am comparing to the issues we have with plasma cutting. Just saying: it is refreshing not to need to worry.

If course you have new challenges like the filament not adhering, running out of filament, sagging of the object and the lengthy time delay between start and finish of the print.

One more post and this topic reaches 300!

BlockquoteOne more post and this topic reaches 300!

Hmm