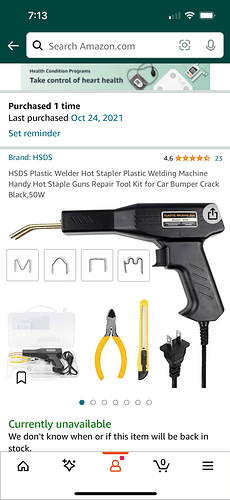

Has anyone did any plastic welding and if so how did it turn out?

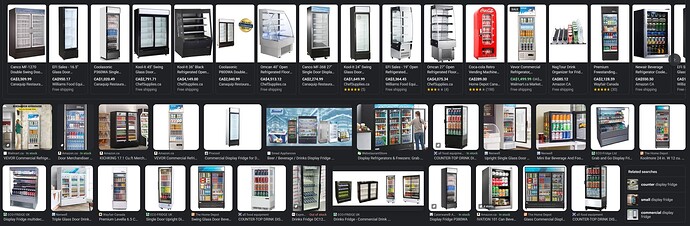

My ultimate plan to solve.

Keeping prints warm

Containing and ducting away vapour

Humid control

Sound

Lighting

Is to source a upright Drink display refrigerator, put it in my office and contain all my 3d printing things inside. The refrigerator part does not need to function so one should come up cheap.

I like this idea. I have several refrigeration vacuum pumps,I though about buying vacuum Chamber? But i really don’t know yet.

A spool is 8" so maybe 3 would fit ?

I watch auctions quite often and I see these type of refrigerated cases all the time

I used to do some plastic welding years ago and biggest thing is knowing what plastic you were working with. I am sure its way more complicated now.

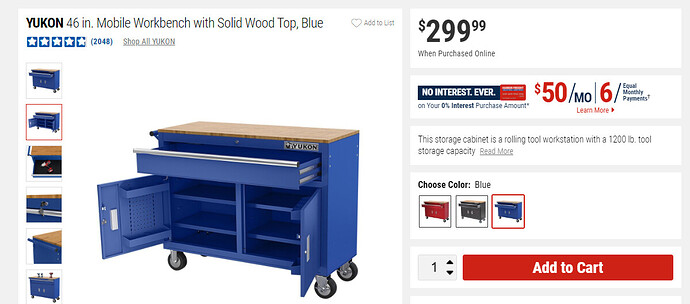

@TinWhisperer - I use this Harbor Freight 26" x 22" x 40" roller tool cabinet for mine. Holds 42 rolls of filament, all my spare parts and tools with the printer on top.

Don’t over think the vacuum part. The simple bags and the hand pump will take a whopping 2 minutes of your life sealing it up, for a 30 bag kit with desiccant and pump is $27 US

Cooking off moisture is still the best way to dry filament…Maybe a food dehydrator, but the oven method is tried and true.

The hardest part about filament inventory…Remembering what you have. I ran out of black PLA+ on a job and chose to stop one print with 9min left, and start the second half (plate) with Red PLA+.

I thought for sure I had another spool of black.

If I was doing as much as you guys, I would have to keep an inventory spreadsheet, and remember to check the rolls in and out of storage and update quantities.

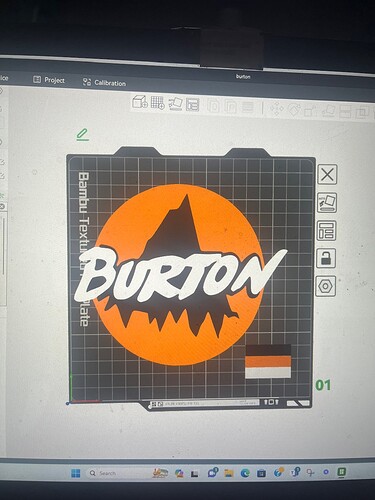

I’m still in the trying to learn new things. I didn’t have much time but started to make stomp pad for kids snowboard. I’ll have to look up how to add clear filament spikes on top as a body.

So many cool things to make with it.

Here is my Harbor Freight solution for moisture control and provide filament storage: have not pulled the trigger yet but this is my plan.

This Harbor Freight cart has a nice open cabinet in the bottom that I will seal up with weather stripping.

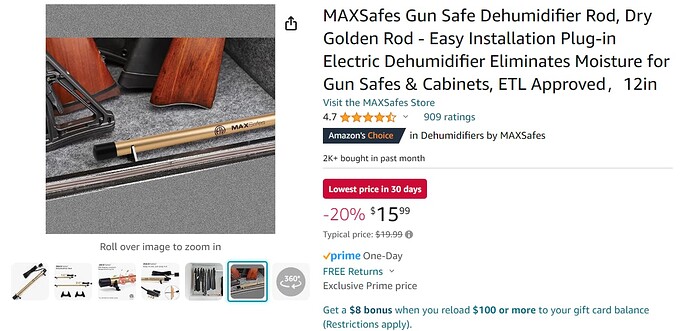

And add a couple of these safe dehumidifiers. I have tried all kinds of things to combat moisture in wet Washington state and these little warm sticks are fantastic. They never get warmer than 130 deg F, last for years and years, and only draw 7 watts of power.

How are you going to seal up the lower cabinet?

@TinWhisperer @ChelanJim - Adam Savage built a combo dryer/storage case that can also feed his printer.

Tape/caulking at the seams of metal and holes. Use weather stripping on the doors.

I don’t expect it will need to be air tight. That is what I discovered with those heaters: you don’t need to worry so much about infiltration of air if the air temp is warmer inside. You just need to make the air still. There is more need for the air to expand out than to come in. Sort of a positive pressure.

Don’t know if it will work but I can always add your vacuum bag idea on top. In our high humidity here, the desiccant does not last in any open container.

Edit: I just looked at the video of Adam Savage and he is confirming my idea to have some merit. His shop had RH of 56%. Inside the AMS case the humidity was 10%. This situation is helped by it being a closed container with still air, it is warm and it may or may not have desiccant beads.

I was thinking about using my marker setup on the cnc table and doing a small plexiglass cabinet. This might be a future project.

Plexiglass does not tolerate the stressors of torque and oblique forces. You would be best to use the plexiglass as the door and not the actual cabinet.

Unless you plan to “weld” all of the pieces. But, that requires a very tight, smooth joint.

I played around with the PLA-CF that came with it this weekend. Did you have issues with yours getting stuck while feeding in from the AMS? I had to cut the end of the filament to a point to get it to feed properly.

I live in a dry climate, so humidity in the house is almost always 30% or less. I just keep them in the cardboard boxes they come in. I have filament that’s over 4 years old out in the open in the house that’s still like new, the only issue is one spool was in the sun and the top layer on it got brittle from the UV.

how the heck do you get your SS cuts so clean w/o all the black nasty dross?

I have one of these next to my X1 for a quick PEI plate paper towel wipe down before printing.

https://www.amazon.com/gp/product/B07G8M3F3S/ref=ppx_yo_dt_b_asin_title_o07_s00

These work very well for long term filament storage

Add some dessicant in a sock / pantyhose and a humidity sensor on the lid.

There’s obviously something addictive in the vapor given off by 3D printers.

You guys make sure to take a photo now, so you can compare it a year from now. ![]()

For example, 2 years meth use:

That would be an improvement of my look. ![]()

@apynckel Argon gas instead of compressed air I’d bet