4 longer rails, 2 longer lead screws and a larger water tray is all that is needed to change from standard Crossfire Pro. The rest is off the self parts. @langmuir-daniel @langmuir-reilly

@MechanicJon Thank you for sharing the idea! I appreciate it and agree a 4x4 PRO would be super useful. PRO expansion hasn’t been on our list of things to work on. However, we just added two new engineers to the team here, once they are up to speed we could evaluate doing something like this. I know we are slow to market with new ideas, but we have some really great things coming soon.

Awesome!!!

Along the same lines as this, maybe consider making the crossfire xl kit so it expands the y to 49 in of usable space instead if the odd 33 inch. With this you’d have a machine thats capable of cutting a full 1/4 sheet at 24 x 48. Its also the perfect in between size between the crossfire and the crossfire pro.

To cut down on cost of shipping larger water pan, it could be made up of 3 pieces instead of 2. Turn seam to match the x axis instead of the y axis like it is now.

I have thought about expanding the cut area of my pro on more than one occasion. One way to reduce the cost of an expansion kit would be to split the existing water tray and rotate it 90 degrees so all that is needed is a new center section of water tray that the existing halves can be bolted to. I thought about a way to extend the table without changing anything on the main table frame. It could be done by using L shaped stanchion plates that would allow for longer gantry rails.

I thought about that also. But you’d need something to support the water tray on the edges. Also i’d be worried about loading a heavy piece of metal and table tipping without additional legs. If you added the crossbar and additional legs the only thing would save on is the longer lower Y axis frame pieces.

I’m collecting the pieces to go ahead and do it myself. I’ve got the 4 pieces in stainless for the longer rails already. A machinest buddy is going to drill the necessary holes on his bridge port mill. I just have to pull a top rail off so he can match the holes needed. Since I welded my pan togeather I’ll have to make a whole new pan up.

I actually made a new water tray for my table last month and I decided to get away from a metallic water tray. I built a new water table using a combination of carbon fiber and aramid fiber and it is all one piece with integrated drainage channels that channels everything to a central drain. I haven’t installed the tray yet due to lack of time. It is autoclave cured with ultra high temp resin. While I was at it I built a carbon fiber water tank for underneath the table and I came up with a really clean carbon fiber cover for the z axis and torch. I haven’t priced stainless steel in a long time so I have no clue what it would cost to make a new stainless water tray.

Make sure you post pictures of all this stuff. It helps brew ideas on other stuff people may be thinking of doing!

Sounds like a great addition to this thread:

Pimp My Pro- Mods and Addons - CrossFire ® PRO - Langmuir Systems Forum

What temp rating does the resin have?

16g 5x10 sheet of 304L stainless is $615.00 in Arizona

5x10 sheet of 316L is $822.00

That’s for one sheet if you buy 10 or more the price gets cut by 2/3rds.

Any Word on this?!

I’d buy that kit in a instance sure lots of people would.

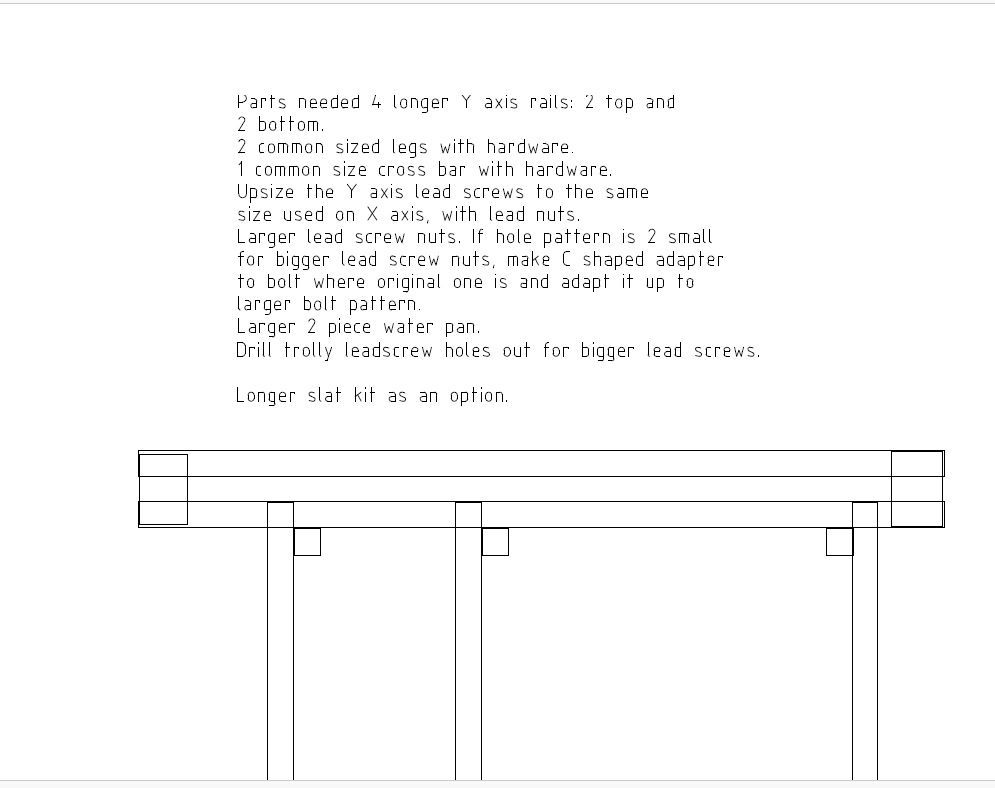

Here is a thread discussing what is needed. I have been gathering parts to do this before the end of the year and in the thread above I have been listing the parts needed with hyper links. I have also communicated with Langmuir to confirm the proper parts needed to get from Langmuir.

The post OP stated his cost was $600. If you only need 48x48 just shorten the rails. I’m going to be doing the full 61” listed. Maybe a little bit longer. I can’t do a Crossfire XR not enough current room in the shop but 61” will work fine.

Good afternoon

After purchasing “plans” and materials for a table for my son and I to build, I have instead purchased a used crossfire pro

I have 2x2 1/8 inch tube for the other build I am wondering if I can use to increase the size of the pro.

I have been following a couple treads and think its doable to make it so it fits a full sheet.

If i can get any input form you I would appreciate it.

thanks Unscripted

The first issue I see would be finding lead screws that are strong enough not to whip excessively when turning and keep the same pitch to keep motor steps correct. Then I am sure the motors would need a upgrade too. The XR uses a different type drive system than the pro. It uses ball screws. I assume that eliminates lead screw issue.

Not saying it can’t be done. When you attempt it please share.

You might have your heart set on having the ability to cut out a full sheet of metal with with one gcode file but as Phillip points out, you are going to feel like you built the table from scratch by the time to re-build and problem solve the hardware and software issues.

You might consider getting a couple of infeed and outfeed tables to support an entire sheet and do “index” cuts with your current Pro table.

Here is a nice introduction of how to split a larger image into sizes that fit on the Pro table.

We are still looking at this along with some other new products. The straightness of the tubes has been a challenge as we get into a bigger table with the traditional Crossfire Pro design, additionally the lead screws are having to get bigger, and we are looking at the water tray too. We will have an update by around year end one way or the other. We always appreciate the new ideas and evaluate all of them here in Conroe. Thanks for checking in on this! We will update you all soon.