Etching with plasma is tricky. Those came out pretty good.

Looks good Craig.

Craig, do you ever shut down or is your brain constantly on exploration mode???

It is all for the better for us. I just can’t imagine.

One should never stop learning.

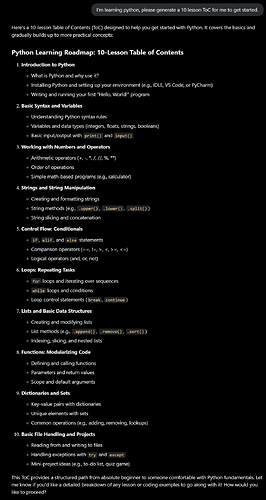

I just started to learn Python recently.

There is no rhyme or reason for it other than, I wanted to learn something new.

Constant exploration mode. I’m now talking to chatGPT while I drive to have it explain things to me instead of listening the music or podcasts.

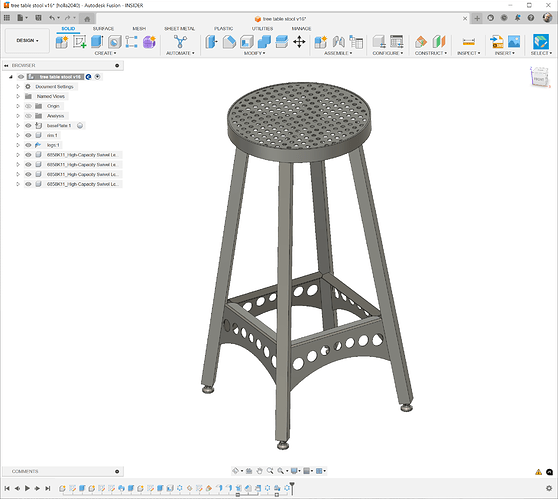

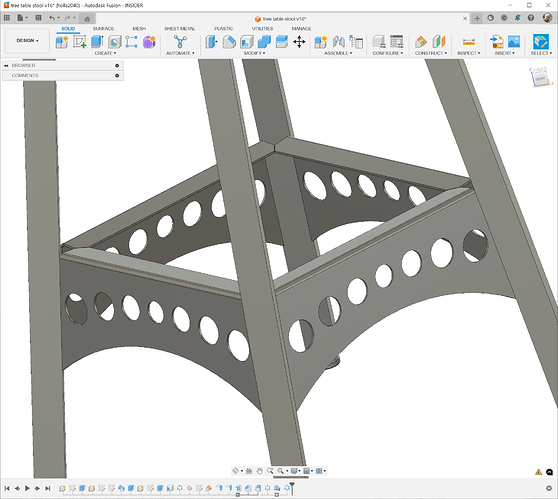

Next project, need 6 tree table stools by June 21st. I started today with a complete cad design. Got the boss’ design approval. Fab starts next weekend!

Have chatGPT or grok generate a lesson plan for you. I’ve been using python for about 20 yrs. One thing you need to clearly understand is its object nature and classes. Other than that, python is sooo easy and forgiving to learn. Good luck, hope you find it useful.

If a day goes by where you don’t learn something new, it was wasted.

A personal motto.

I for one would like to learn that fancy plasma etching wizardry.

Can’t wait to see the finished look. Keep up the good work.

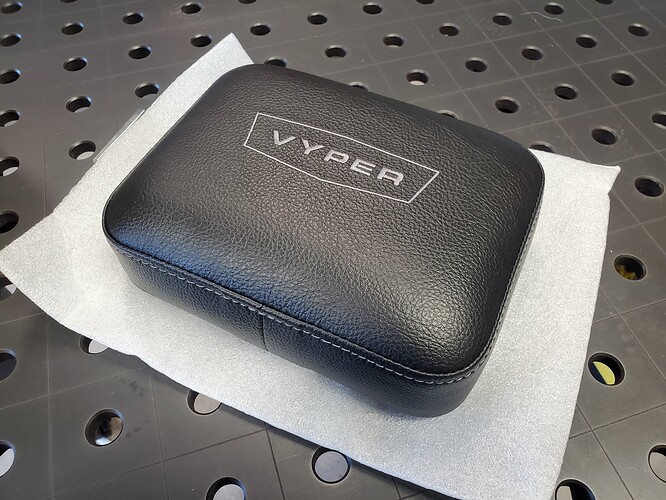

Pad arrived finally

I thought the small pad wouldn’t have provided much comfort but boy was I wrong, it feels nice and supportive

Just needs the footrest welded on, some paint, and she’s done.

Edit, not long after I posted this UPS showed up.

No more using this -

And instead, using this -

Just need my footrest now!

Looks great. I think you’ve inspired me to build one to replace the old office chair that I use for welding.

When the pad arrived, I was a bit skeptical that it’d add any real support.

Granted I’m not a big guy by any means (on the shorter side), I still found it to be nice and supportive.

Having a ton of leather left over though, I may still want to make my own at around 7" x 10" or so.

The Vyper pad is only 6" x 8" but it is comfortable.

Also the backrest I made has a tiny bit less angle and is quite a bit shorter than the one you shared. Still, it was super helpful.

My buddy is a tattoo artist and he sits in it backwards and leans his chest on the back rest for support. The original backrest was too short, so he asked me to make the longer one.

That makes a ton more sense!

Probably why I felt the need to edit it. I was using the one I screenshotted earlier as my initial mock up.

Someone made a comment about not hitting my car by accident with the stool ![]()

I expect this should work well.

To nice to use that for shop use

What no way, I’m making it so I DO have a dedicated shop stool.

It’s why I opted for real leather, a resilient HD foam, and a wrinkled high temp paint.

The foam is good for +10 years and meant for autos or boats, so it’s made to resist moisture and humid environments.

Had a little bit of time today.

Not sure if I mentioned this before or not but the Vyper backrest pad is a placeholder.

Feels cheap so it’ll be going back and replaced by a DIY variant using left over leather I’ve got.

Glad I got the paint done evenly, it was a bitch seeing how awkward the base is.

After some 24 hours of curing, it’ll lighten in color to match the remaining parts I painted last week.

I was inspired by @Kwikfab to build a new shop stool for my welding table.

I found the seat on a cheap stool that I bought for my daughter when she was in college. As it already had 4 holes for mounting, I designed the seat mount and back rest support as one piece.

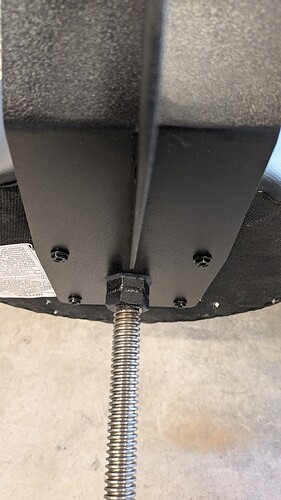

The nuts that I used to mount the acme threaded rod to the seat base were actually the drain nuts from the crossfire pro. The threads were wrong, so I bored them out on the lathe and welded them together.

I’m still waiting on foam to make a back rest pad.

Sick!

Man you knocked that thing out quick. My buddy got my backrest panel out to me before I left town so I drilled it out super quick and threw on some t-nuts before dropping it off with the upholstery shop.

Hoping it’s done once I’m back in town this Thursday.

Opted to make the panel 7" x 9" as opposed to Vyper’s 6" x 8".