Store it upside down as propane is heavier than air.

Don’t forget to roll your gas cylinders to keep them properly mixed!

Being a non-sign guy, I don’t paint shit.

With that said, this VHT paint really came out nice and even.

Looks fantastic!

Oh, I sooo wanted to edit that!!! ![]()

Thou protest too much, sign guy!!! ![]() Embrace your inner sign-guy self. Let your freak sign inspiration soar!

Embrace your inner sign-guy self. Let your freak sign inspiration soar!

![]()

![]()

![]()

![]()

![]()

![]()

Nice video, I was disappointed that you never mentioned anything about sending me all your laser stuff so I could try it on my table to gain some more test data

But as I thought about it more, I guess you would want someone who has the plasma side dialed in before testing any laser stuff ![]()

Ya sending me stuff would be a bad idea, never mind

Thank you brosef

I couldn’t contain myself, so when I got home I flipped it over to get the other side done

As it gets warmed up, it begins to wrinkle

Wrinkle in full effect

Now I can actually leave it alone for a few days

I’m old and can’t remember who asked for what and what I said. You however are rockin’ the plasma!

You are probably on to something with the acceleration and the program ability to navigate the cut profile, and the lack of precision in the X,Y system.

The distance is too short to actually achieve the 250, or even the 175 before it has to slow down again for the next turn.

I know that with 3D printers that claim super high print speeds, there is X distance that it needs to have to reach full speed, and most prints that straight line is too short to make it.

Print something at say 500mms on one printer, and the same model on an identical printer but at 200, they both get done at the same time due to the geometry of the model.

ETA - good on you. It cut, you feel it meets your mechanical needs, don’t need to waste the brain power making it visually perfect. Wavy edges or straight, it still keeps fingers or whatever from getting to the fan blades.

Duh, of course! I hadn’t even thought of that. That’s why the results are near identical. Thanks for thinking of that.

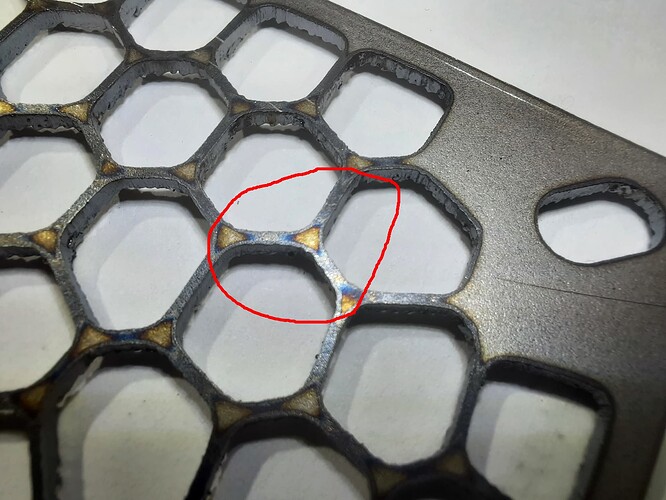

After @Sticks comment about feed rate, acceleration and small cuts, I re-ran my fan example at 80IPM and 600W. Dramatically improved top side edges on 18ga CRS. Circled area is the bridge joint shown in previous video.

That is so much better!

Sticks has been around the block, he knows what he is talking about. And no doubt, he has mowed down a few mailboxes on the way.

That laser torch looks quite large. How much more do you think that weighs compared to a machine torch?

Looks hella better.

Started making a Can-Am Clutch tool for my Can-Am Outlander ATV. As you can see I put some labels on it. The Clutch tool part came out OK but the Made By Tim… Not so good.

Labeling your tools is a OG move. Everyone that barrows it will return it! Nice work.