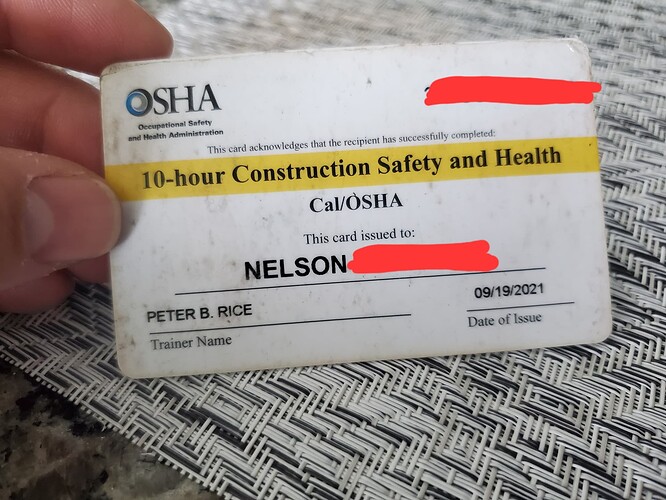

EXCELLENT! OSHA APPROVED! ![]()

Your stool base looks great Nelson, Thanks for sharing!

Ha thanks!

Once it’s done I plan to toss up the DXF for download.

This is a great project! Thanks for the post.

Awesome example of proper beveling and fixturing, can’t wait to see the final product.

I really should ditch my “upcycled” fabricobbled sheet-on-pipe welding table for a couple good fixture tables.

Im not really clear on that brand of table, could we get pics? I am a visual kinda of guy ![]()

I have used a 10 x 5 x5/8 A36 plate as a welding table for 30 years. It doesn’t have a name, though. I believe I will name it ROXANNE this morning…

Meet Roxanne.

Well this thing was salvaged from a belated farrier up in Lufkin. Something to “work for now” that his widow was kind enough to not charge me an arm and leg for. But it’s bumpy, definitely not level, and the legs are uneven from it sitting on pebbles/rocks/dirt and settling itself in the previous life.

The work surface is pretty much perfect in area, and it’s conductive, so i guess it has those working for it. I’d just rather have something that was flat with more ability to rigidly clamp work to. Really only the front 3" is accessible for clamping down to the table surface.

I don’t know how us old timers survived without holes in the table.

Do you just weld on reference jigs to clamp to?

I tack weld whatever I need to the table. It cleans up nicely afterward. The holes in the table are not ideal for my operation. I get it, though.

That’s how we did it at my first fab job.

Everything gets tacked onto the table itself.

Hey! Maybe I should go back to Welding school! That’s what happened to me when I tried to learn how to weld, the piece ended up being welded to the table! ![]()

Technology happens. Advancements. Finding better ways to make things easier and better. How on Earth did we survive before cnc?.. and limit switches?

Ohhh, Sticks, you didn’t just do that!?!? ![]()

Oh yea he went there ![]()

I hate to say it, but @Sticks is correct. I still hate the limit switch issue. I also don’t want holes in the table we work on all day. I can see it now parts, screws, bolts, etc, falling on the floor through the holes. Like I said, 30 years, and I have not one inkling to have a table with holes. Just my observation.