Wow! A million dollar table. They could offer a 90% discount and I still couldn’t afford it.

That’s a beast.

Here is a little project I did a couple days ago. I have a small shop and need to roll things out of the way or take them a part and store them out of the way. This will do both. The base was from an old office chair. I piece of pipe I had and some 11 gauge steel, and now I have a stand-up computer stand. It is painted now and the large mouse pad is cut to size.

If you do this again, I would recommend 5 legs/casters on the base. It’s much less likely to tip over.

On the other hand, maybe that recommendation has been revoked by now… ![]()

![]()

Just using up what I had. It seems real stable though. I tacked it together and used it for a few days before painting it. There were no indication of it wanting to tip at all.

A post was merged into an existing topic: About the Buy and Trade category

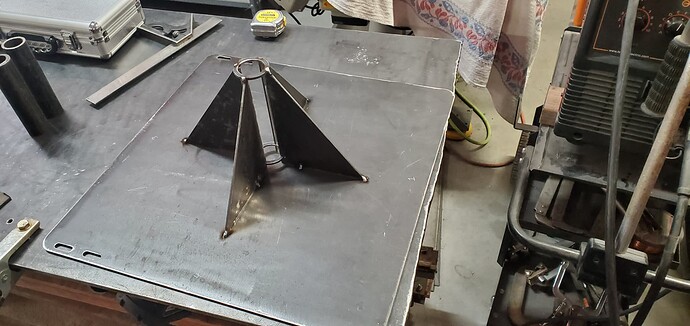

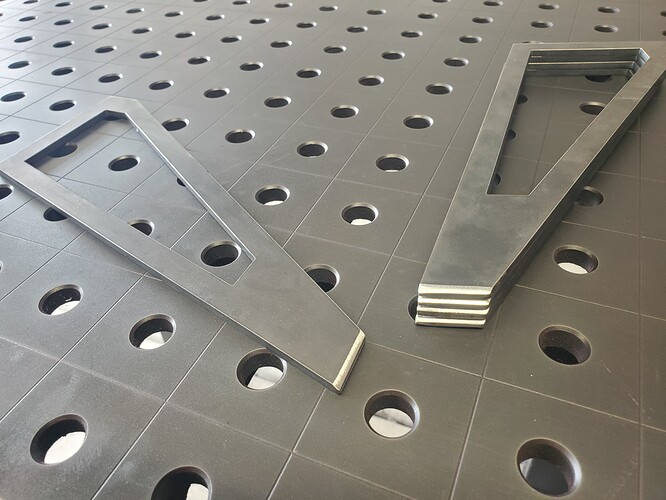

Here is one that is ready for paint. This is to big for my oven so I sub it out.

It’s some type of wall decoration for a Hotel remodel.

That’s the kind of thing that proves the value of your fixture table. Looks great Knick

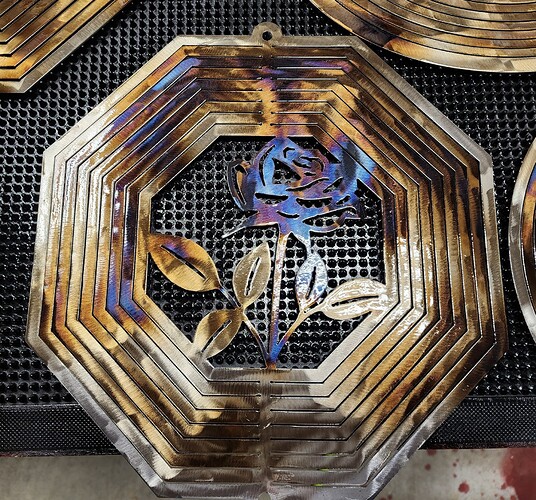

I’m stoked to finally have something to post up here. Feels like its been a long road to get some finished products.

The plasma is cutting good now! ![]()

I dont get it? Am I missing something?

That’s impressive! Did you Design the whole thing?

Knick, he cut the vertical gate bars to inset the sign to gate. The bars would have been in background of the sign, they are welded to top and bottom of border of the sign.

Like Richard said: I just added the bars into the image to show how distracting that would have been. Since he removed the bars, the sign was easily readable and aesthetically more impressive.

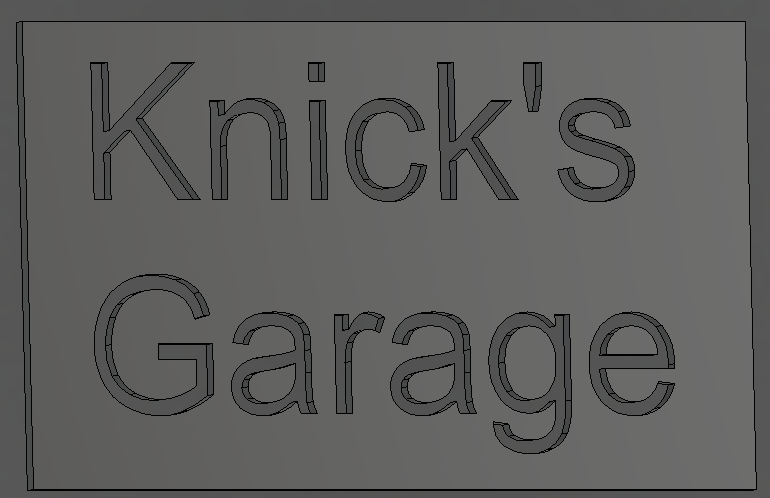

Many times people will make a sign and not see it the way others may see. Another example is when they use a font that may be so fancy or obscure that the reader may not know what the sign is trying to say. Those people familiar with it, instantly know what it says and are not trying to piece the letters into a meaningful message: Knick’s Garage

Easy to read:

A struggle to read if you don’t already know the business name (at least for me):

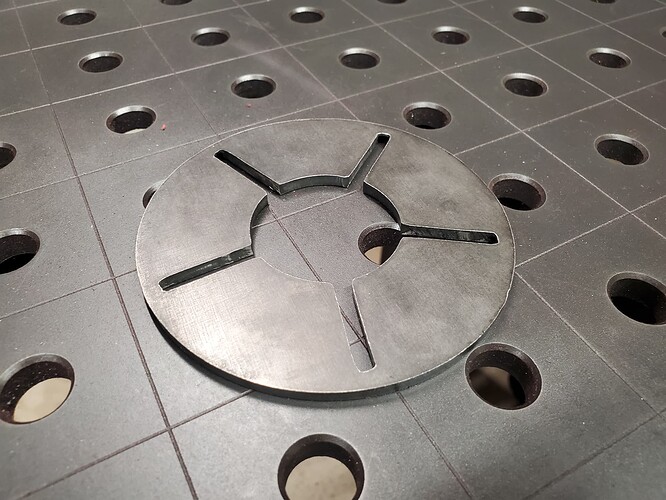

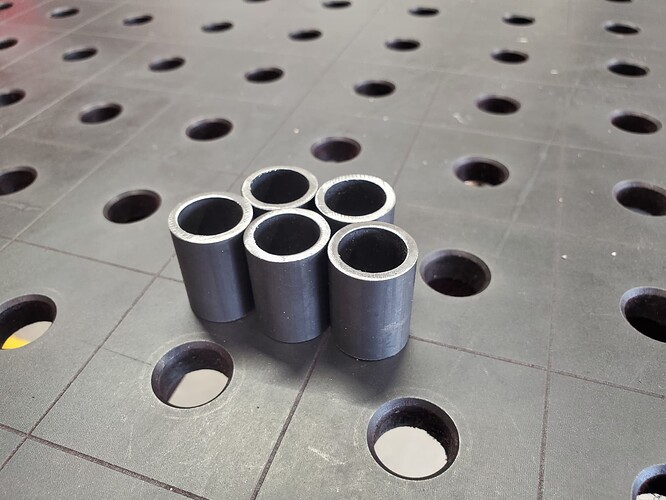

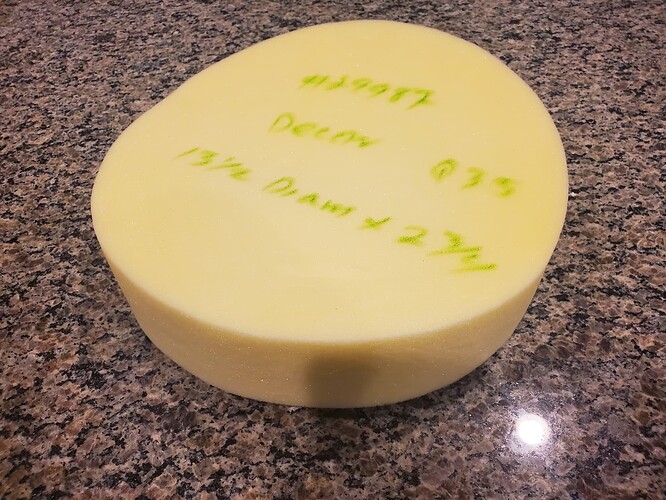

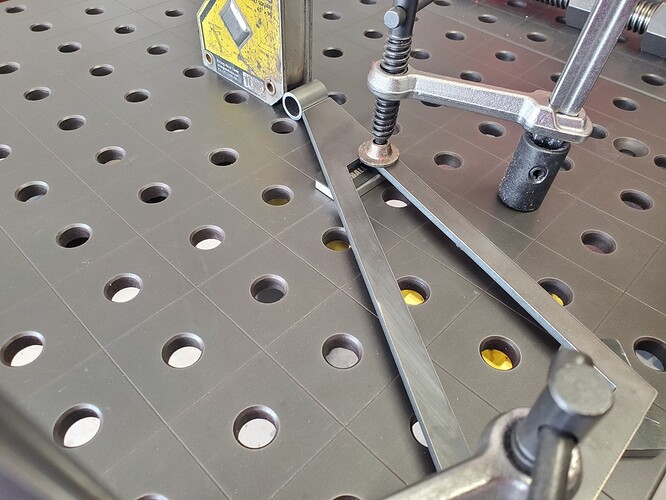

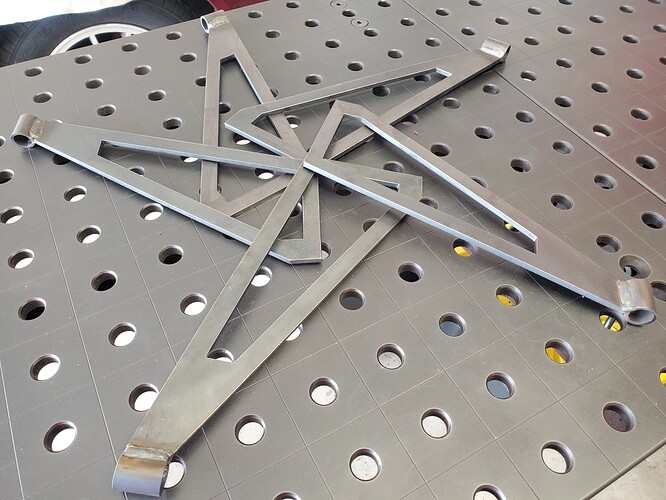

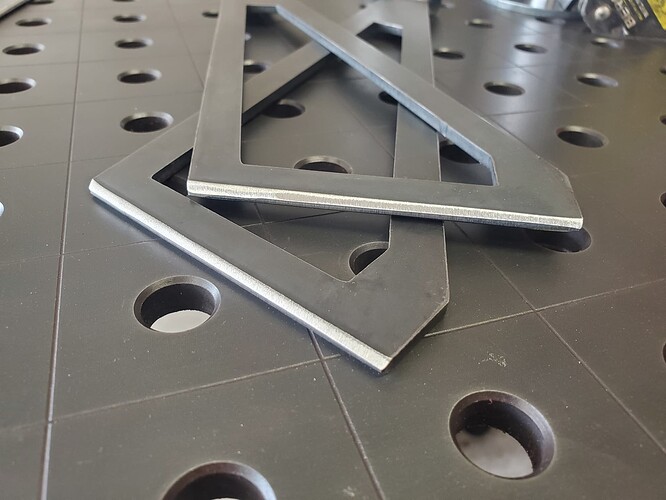

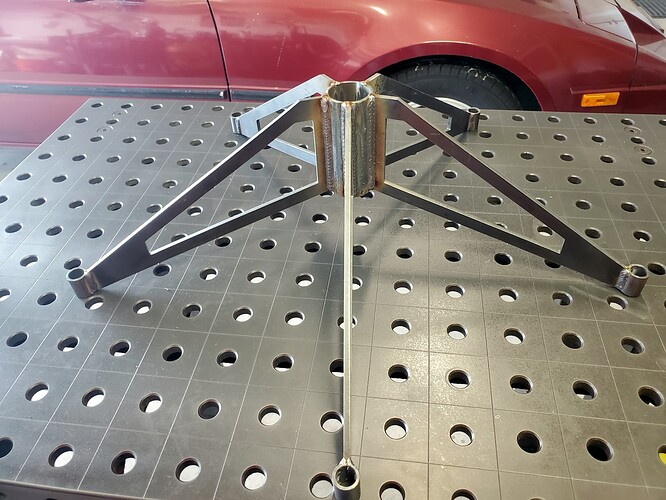

Cut some parts the other day.

As well as having bought some, most of them just arrived minus the wood top and t-nuts.

Prepped and glued most of it up yesterday.

As it sits now.

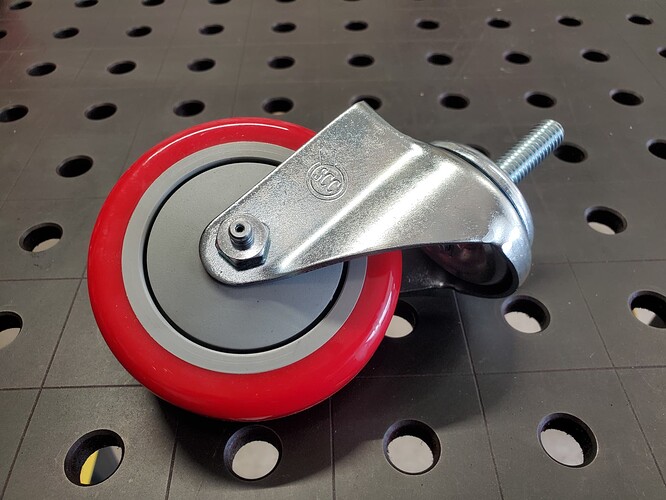

The casters aren’t fully bolted in place, just wanted to ensure all the casters touch the ground and it does all over where it’ll roll around.

Will be able to finish it once the remaining parts arrive, and after I either find someone to bend some rod for me, or if I compromise and use a flat round ring as a foot rest.