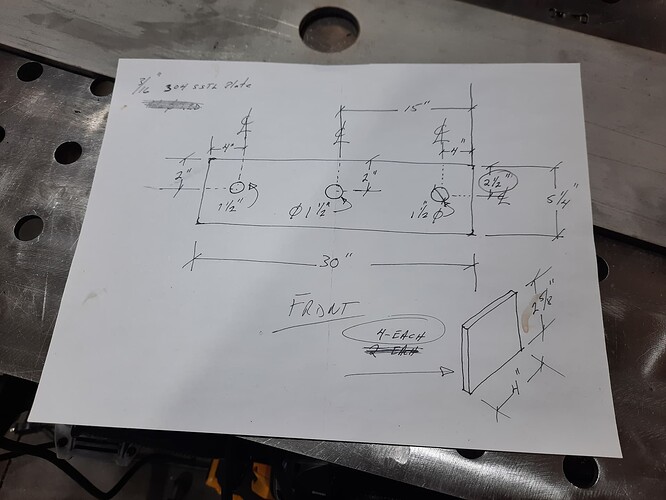

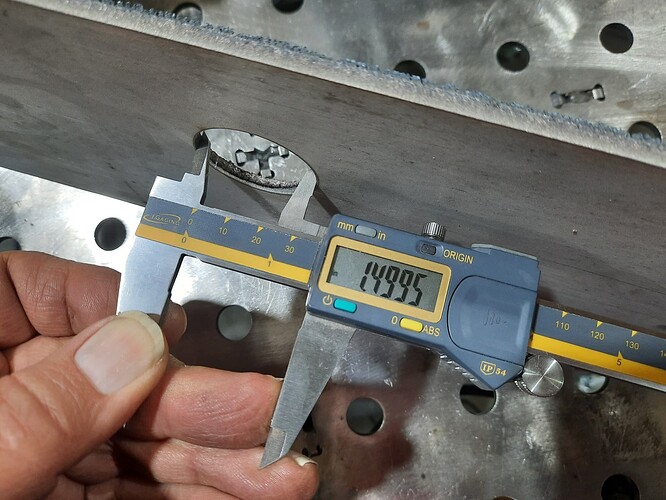

That’s the pucker factor then.![]()

Screw ups are not cheap. You can instantly vaporize profit.

They look liked they came out very nice!

Excellent idea!

Yes they are. I picked up a 50w fiber laser in the fall.

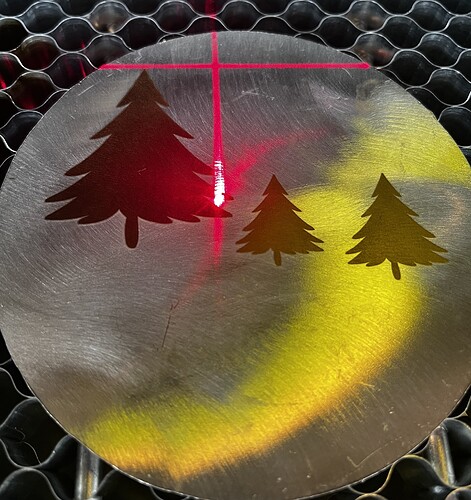

What did you coat the steel with? Is that a blue diode laser?

The cutter I bought has two laser modules. One is a 40 watt blue laser. It is used for non metal cutting and etching. The metal etching though, is done with a 2 watt IR laser (1040 nm). With the IR you don’t have to coat the steel with anything.

This is just a test piece in CRS. The different colors come from varying the speed (feed rate) of the laser. Basically this is very controlled torch blueing. Haven’t tried SS yet, but that is next

Can you share what machine you bought ?

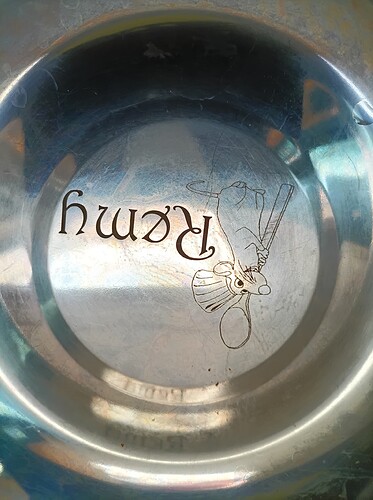

I had the power waaaay too high when I did the inside of Zero.

I’ve also done up some business cards, wedding invitations (on business cards with magnets on the back) re-etched the pocket caliper I have - 1/32 lines accurate to 1/64 over 5 inches. A couple tumblers and a ring inside and out.

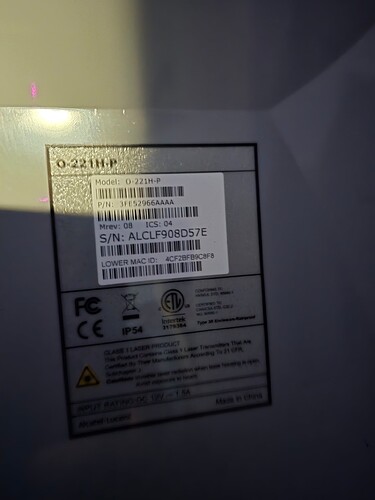

We bought an X-Tool model S1 with a 40W blue laser and a 2W IR laser. I bought this machine sepcifically for the IR laser and its ability to mark metal directly with no marking fluid. We bought a package deal that had the conveyor and rotary tool as well

@holla2040 , have you patched you table and tried water with additive yet? Wouldn’t an opaque liquid protect the pan?

What opaque liquid would you suggest?

@holla2040 those cuts look excellent

Cutting fluid obviously. Anything that would absorb/diffuse the light energy.

the 1/4 " piece of steel at the bottom of the pan works well too

Thanks Tim. As for the opaque liquid, we plan on building a different base for the XPro and ditching the water trays. However, we have a different potential issue, the laser energy damaging the shop floor. We address that if we see it happening.

Although I know very little about laser tables, the 12000w laser table the local shop used to cut stainless steel featured a honeycomb mirror material. Next time I visit that shop, I will ask about it.

$900,000 Table made in Germany. 480v three phase. It literally had light beams all around it to keep people from getting to close to the sheet loading area.

https://youtube.com/shorts/taLfcuEZeXA?si=tc-TUzwCvtk7Ncwe