Why the tabs?

If you did that on a CF Pro…Wow.

Wow anyways. Looks nice @reid913

Very nice, do you have any stats while cutting? pierces? cut time per panel?

Thank you sir appreciate your kind words. Stats I’m remembering.

The man in the picture is Glen

Everlast 102i

Ipt 100

XR table my mistake I didn’t realize this was cross fire pro I used to have a crossfire pro.

Settings

14g A36

73psi

1.2 mm nozzle

40 amps -50

115 in/min travel speed

.5 sec rest after each cut

.125 lead in and lead out arc

I had a spray bottle to spray the steel as it was cutting really a two liter with a hole poked in the top. Water table was filled to the brim plenty of splashing. The rest at the end of the cut helped spray dirty water everywhere.

A lot of pierces about an hour per two panels

I’ll have to look

The picture was draw by hand then I took a picture. Then went into Inkscape traced the lines and vectorized in. Then went to fusion to place triangles on top of image and put bridges in. Sheet cam post processing. Looking forward to installing plastic panels on the inside then there is another frame that fits inside with the LEDs and pump I got a 5000 gph pump on Amazon hoping it does the trick. This is the first fountain project.

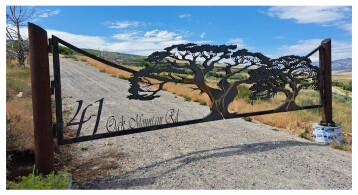

Definitely another two for the “wall” @langmuir-zachary, @langmuir-alex , as well as @Ammocan contribution with the gate above.

You know we will love to see photos when you have the fountain running.

… and the location so we can pin it to Google Maps!!! (Just kidding on that one)

New season on the farm, time for a new creation. Deere has used the same junk tiny toolbox for the last 40 years so I figured a mounting spot for a packout. The best way would have been to completely rebuild the step and have packout slots in it, but I can only bend 37" and its a 45" long step. I think if I were to do it again I would just have the local shop do those bends for me. My mount is plenty solid and could totally be a step, but its a lot of leverage on the factory step mounts.

I’m curious to see how that holds up does that stay on the tractor all the time and so it’s bouncing around? How much do you think it weighs?

The box maybe weighs 50 ish by the time I throw some tools in it. I was walking on it and its pretty solid. It flexes maybe an inch with 180 pounds standing on the edge. The bracket has zero flex, but the factory step has some give to it.

Ive got one sold to a neighbor too so I guess I’ll have 2 demo units out there

Necessity and creation. Nice.

Make it a two piece, weld them together and replace not add to the factory step. That will remove leverage, and reduce the bouncing that will cause stress fractures and unintended asset relocation and liquidation.

Yea that thought crossed my mind. My other concern with replacing the step is heat. That shield is perforated for a reason. Might affect the cooling of the hydraulics behind it if I throw a big packout next to it.

Made a couple changed to v2. Changed the geometry on the side flanges. V1 I layered the side flanges with another piece of 10g. Did it from 1 piece now, with a small reinforcement welded on the side with the notch. Then i got to looking at the combine frame and realized I could add a support for the factory step pretty easy. Burned a set out of 1/4. I’ll install them tomorrow after the paint is dry and see if it helps.

Well there goes the testing on the first design. ![]()

The first design is on my combine. 2nd design is going on the neighbors. Hes got the same exact machine as mine. His was actually built the day before mine. When you buy a new deere you can do a gold key tour on the day yours is built. You get to do the first start on the assembly line. He told his tour guide we were coming the next day so they went and found our cab before it was installed so he could sit in our machine first ![]()

But the stiffening plates are going on both machines. Seems like a no brainer easy fix for me.

Just so you are aware, be careful about advertising anything with packout holes and compatibility. It is patented by Milwaukee.

I received a cease & desist letter from their attorney over my packout drawers and shelves… They are super aggressive. I know a guy that is being sued now because he ignored them. And Klein tool is being sued as well.

Cheers.

ISTM that is a very shortsighted thing for them to do. It seems as if providing EASY licensing of the slots would promote compatible shelving thereby encouraging the proliferation of their mainstream products. Are they in the business of selling shelves or tools for goodness sake! ![]()

Of course I agree but the giant machine doesn’t care.

I proposed (and many others I have learned) a “signature designer program.”

was ignored….

They apparently dont hop on etsy very often ![]()

Although an easy way around that is to just sell mounts that facilitate their mounting plates. Its not quite as streamlined as a one piece, but its significantly cheaper to use their plates instead of cutting them out. Also makes potential shipping much easier.

I already have an entire modular cabinet system that does that.