Been on an aluminum kick lately. Made this out of 14, bent and riveted. Gotta make the bottom yet. It’s a clean out hopper for the Deere planter. Fits right below the row unit to catch the corn when you take the unit apart. The factory one isn’t big enough to catch everything when you are blowing the lines out to change crops. It fit decent, didn’t get a chance to try it after assembly. Riveted it together on the kitchen table instead of in the shop ![]()

why is is when I see the picture @Cletus posted of his shop …I get this image in my head…???

Fits pretty good, might have to trim the bottom and add some edge trim to keep it from scratching the paint.

There might be enough room for an Engine Lathe in that space…

Agreed! ![]()

![]()

Reading through old post. I Could Not agree more. I have started preping product for actual customers not just friends. The amount of time I spend preping something for an $8 rattle can is the same as powder. I have the money just have not pulled the trigger in finishing the oven. I currently have the rockwool and metal framing for a 4’x4’x7’ oven. Just need the control panel and skin…

Then I will not have to worry about the slightest knick scrathing the surface down to bate metal…

If that’s inside dim’s thats the same as mine! Good luck with it

Im doing it as panels because Im not in my shop yet. So the inside will be 48"’ wide and 41" deep.

Thanks

I just got the same computer for mine.

Good luck with your build!

From an industrial oven salesman (in a previous role), be certain you install a secondary overrun protection controller (with it’s own thermocouple) on top of the main controller, and don’t run mechanical contactors. They will weld shut over time and induce a run away condition. SSR’s at minimum but a silicon controlled rectifier would give far better thermal control of the volume, if you ever wanted to use the oven for any other purposes that might include a ramp / hold profile.

As of now I’ve got 1300 acres on my infurrow application brackets. Working pretty good. I’ve got a couple that got bent back a bit from hitting something in the field. Being 14g they bend back into shape pretty easy.

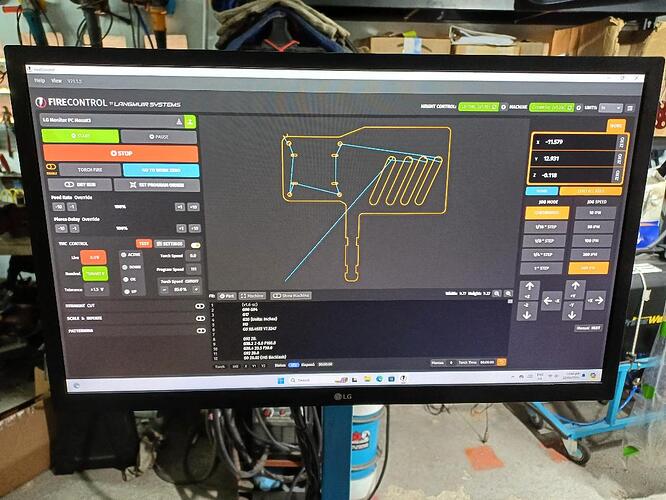

A nice big Hospital check came in last week for some work I did for them with the plasma table, so I gave in and bought the Limit SW Kit. Just installed it, so now I have a fully loaded, up to date, completely serviced, Crossfire XL. I just love this machine! ![]()

only @Cletus could make the Limit Switches work and like them…lol…

Now that is the truth.

My limit switches are unplugged. Used them exactly zero times. I would have sent them to you for free ![]()

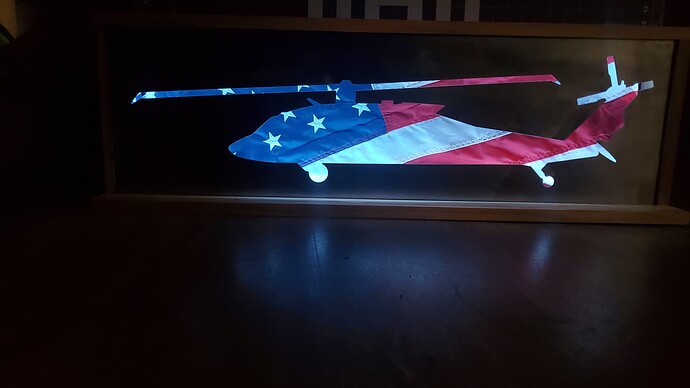

Im pretty happy with this shadow box. When I started this journey 6 months ago my first request was a blackhawk. When I finished the drawing and cut it I realized there was a huge waste. Well I think I have figured it out.

35" x 11.5" x 3.5 box with a made in the USA swen (not printed) flag and a strip of led lights.

Im pretty happy with it.

I have been trying to figure the BH out as well, every one that I make just looks too cartoonish. I like what you did here, nice and simple profile but with detail like UES. I’m a L guy myself so I’ll just have to straighten those tip caps out a bit haha. Nice job man.